Spinning

2025-11-25

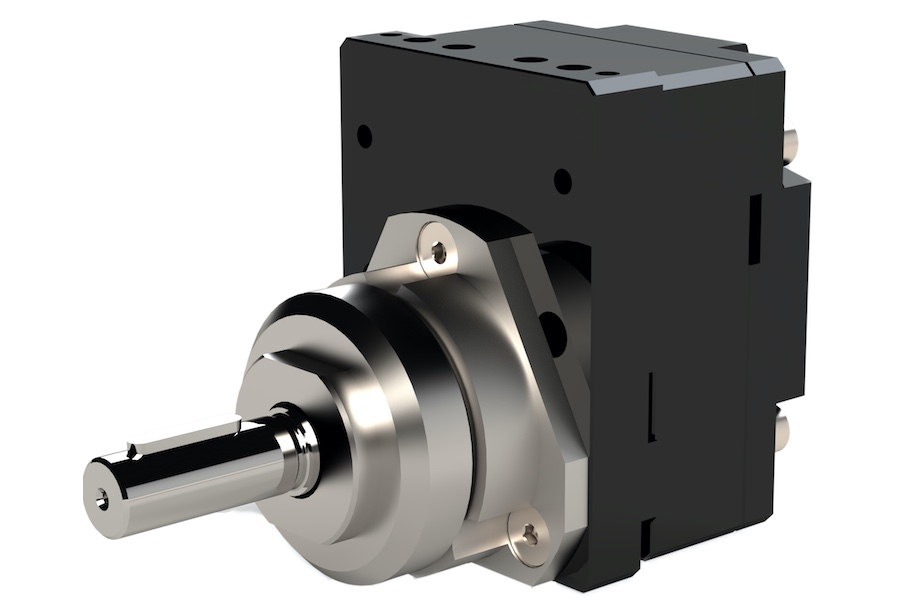

The planned acquisition of the “Barmag” Division of OC Oerlikon will create the leading system provider worldwide for natural and man-made fibers. Rieter is confident it will receive all regulatory approvals to complete the acquisition in the fourth quarter of 2025. The Rieter Group is therefore adjusting its Group structure as of January 1, 2026, to take this acquisition into account and to be able to provide an even more agile response to market challenges.

...more

Spinning

2025-11-20

Barmag, a subsidiary of the Swiss Oerlikon Group, will commission three HMLS yarn systems with a total of 30 stations at renowned technical yarn manufacturers in China over the next three months.

...more

Spinning

2025-11-13

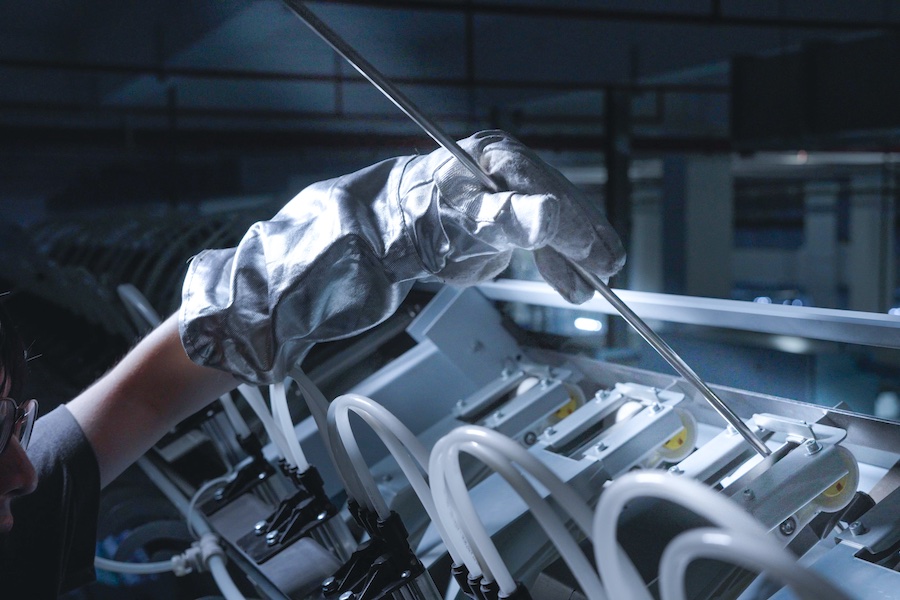

Fibre Extrusion Technology Ltd (FET) of Leeds, UK has completed its second major exhibition of 2025 at ITMA ASIA in Singapore, which is aimed at the textile and garment industry in South and Southeast Asia and the Middle East. Once again, this trade show proved to be a successful one for FET, with considerable interest from several countries surrounding China.

...more