#Spinning

Trusted by experts and driven by innovation – Autocoro 11

The Autocoro 11 from Saurer sets new milestones in the world of rotor spinning. The impressive fully automatic rotor spinning machine is not only the longest of its kind, but also a true masterpiece of efficiency. Over a length of more than 100 metres, it accommodates an impressive 816 top-class spinning positions. What particularly characterises the Autocoro 11 is its amazing potential in many areas. Besides significantly reducing spinning spinning costs - whether for energy, raw materials or personnel - it also enables effortless operation. Large LED lights at the head and tail of the machine provide an optimum overview, keeping the operator constantly up to date without having to walk the entire length of the machine.

Thanks to the innovative Synchropiecing 60 technology, 60 piecers start simultaneously and bring even the longest machines up to speed in just a few minutes. The new yarn guides on the winding unit are a real game changer! Whether for pure cotton or blends with recycled fibres - they extend the cleaning intervals by at least 10 times, as the dirt-resistant yarn guides clean themselves! The new design minimises the surface area for deposits and an integrated pneumatic cleaning system also ensures absolute cleanliness. A breakthrough for maximum efficiency and minimum maintenance!

“Switch on and produce smoothly - that's what counts for us. With 18 long Autocoro 11 machines, we need a quick overview, and the LEDs on each machine give us exactly that: an immediate performance picture, without unnecessary travel. This gives us full production reliability and allows us to deploy our staff more efficiently", says Burhan Kaplan, owner of Biska Tekstil, Türkiye.

Autocoro 11 - champion in energy efficiency

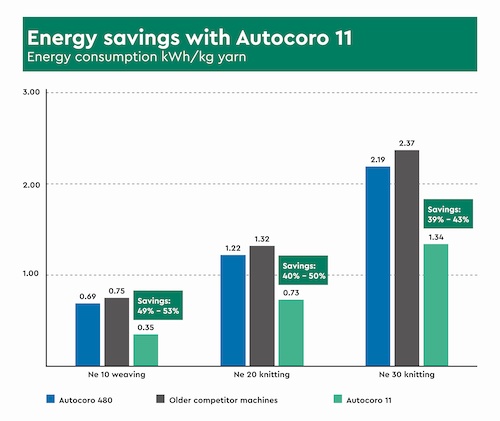

Energy is the second largest cost factor in automatic rotor spinning mills. The Autocoro 11 from Saurer minimises electricity costs by up to 10 % compared to the previous generation and thus immediately increases the profitability of spinning mills. Compared to older rotor spinning machines, the savings can even be up to 48% (Fig. 2). Yarns spun on the Autocoro 11 also have the lowest energy consumption of all spinning processes.

Innovative air logistics for saving energy

A large proportion of the energy requirement - around 30 % - is accounted for by the provision of the vacuum by the suction system. Saurer has fundamentally redesigned the suction system and air logistics of the Autocoro 11 (Fig. 3). With modified ducts and a significant increase in capacity, the new supply ensures resistance to pressure fluctuations, supported by modern air filter systems and a revised electronic control system.

Reliability and performance with energy saving drives

Like a tireless workhorse, the winding unit of the Autocoro 11 winds tonnes of yarn every year. Equipped with powerful yet energy-saving drives and innovative electronic components, such as optimised power supply units, the Autocoro 11 makes a decisive contribution to a positive energy balance. Even with moderate energy prices of 0.10 EUR/kWh and relatively short machines with 480 spinning positions, spinning mills can achieve considerable cost savings in the six-figure range year after year, for each individual machine.

“We are really excited about the Autocoro 11, with savings of up to 30% in energy costs compared to our semi-automatic machines and an impressive 10% compared to previous Autocoro models, it shows how progress is redefining our efficiency", says Fahri Polat, owner of Polat ?plik Tekstil, Türkiye.

Recycling with Autocoro 11

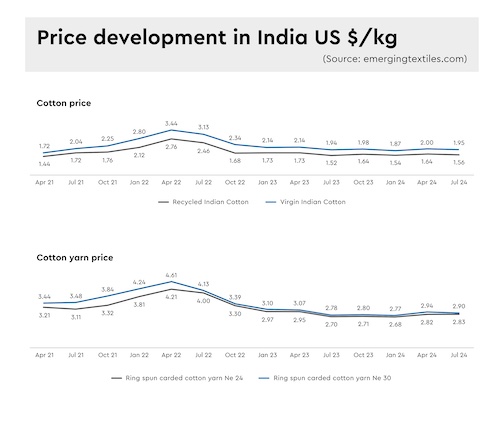

The last few years have clearly shown that raw material prices are volatile, doubling and halving within a few months. Yarn prices do follow raw material prices, but usually more moderately. In challenging times, such as weak demand or an oversupply of yarns, raw material costs can account for more than 80 % of the spinning mills' selling price. One promising way to save costs is to increase the use of recycled cotton fibres, which are on average 19% cheaper than conventional raw cotton in India, for example (Fig 4).

Smart settings for recycled fibres

Although conventional raw cotton can be processed with up to 30% higher productivity compared to recycled fibres, this is often not enough to compensate for the high raw material costs. Recycled fibres offer a more economical solution - but require precise adjustments to the spinning machine. By fine-tuning the yarn twist, speed of the opening rollers and rotor size, it is still possible to achieve a yarn quality that almost matches that of raw cotton. The Autocoro 11's wide range of adjustment options open new ways for spinning mills to achieve greater profitability and flexibility in yarn production.

Innovative Recycling Xtreme technologies

In addition, the Autocoro 11 Recycling Xtreme edition offers more options for processing mechanically recycled fibres, which are extremely short and generate a lot of dust and fly. Recycling Xtreme features a new cleaning system for the rX yarn guides and dirt-repellent surfaces for the opening rollers. The fibre beard supports of the SE 21 spin box can also be easily adapted for very short fibres.

The new patented rotor cleaning technology of the Doffing Cleaning Unit (DCU) keeps the rotor groove clean. The extraction system inside the machine removes waste even more efficiently. With an innovative three-chamber system, the waste can be collected and easily fed back into the spinning process. The Synchropiecing 60 technology increases the Autocoro 11's piecing capacity by 65%, allowing it to maintain high efficiency even with the high breakage rates that typically occur when using recycled fibres.

Autocoro 11: Synergy of efficiency, economy, and sustainability!

With its pioneering technologies, the Autocoro 11 impressively demonstrates how spinning mills can produce economically, efficiently, and sustainably with the help of the Autocoro 11. The Autocoro 11 offers tailor-made solutions for every spinning mill and every type of yarn and fibre.