#Spinning

Rieter closes the financial year 2024 with a solid operating result

Order intake

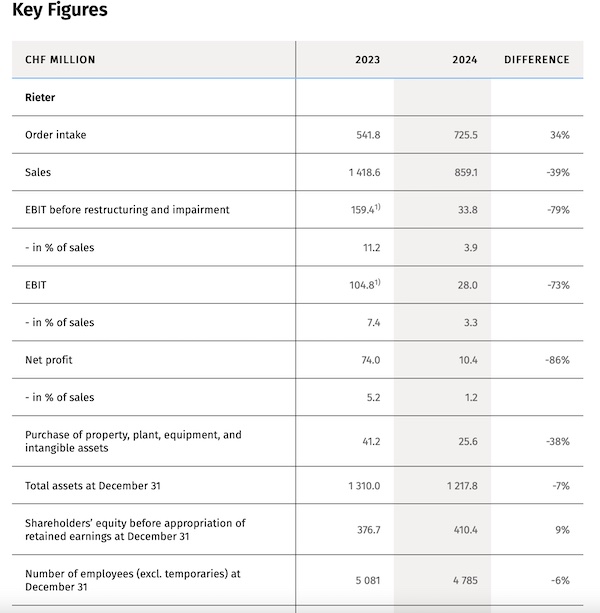

Order intake in 2024 was 34% higher than in the previous year at CHF 725.5 million (2023: CHF 541.8 million). Rieter thus succeeded in strengthening its competitive position in a challenging market environment. An initial market recovery was visible compared with the previous year.

Sales by division

The Machines & Systems Division posted sales of CHF 424.9 million, a decrease of 56% compared with the previous year (2023: CHF 965.0 million). In the Components Division, sales declined to CHF 247.6 million, down 7% from the same period of the previous year (2023: CHF 266.2 million). The After Sales Division reported sales of CHF 186.6 million, comparable to the previous year (2023: CHF 187.4 million).

Order backlog

At the end of 2024, the company had an order backlog of about CHF 530 million (December 31, 2023: CHF 650 million).

EBIT, net profit and free cash flow

Profit at the EBIT level in the year under review was CHF 28.0 million (2023: CHF 104.8 million), which represents an EBIT margin of 3.3% (2023: 7.4%). Despite significantly lower sales, a solid EBIT margin was achieved. This is mainly due to the consistent implementation of the measures set out in the “Next Level” performance program.

Rieter closed the 2024 financial year with a net profit of CHF 10.4 million (2023: CHF 74.0 million).

Free cash flow amounted to CHF 14.1 million (2023: CHF 118.7 million). Net debt increased due to new lease liabilities in connection with the Campus in Winterthur to CHF 230.3 million (2023: CHF 191.2 million).

The equity ratio as of December 31, 2024, rose to 33.7%, mainly due to positive currency effects and lower net working capital (previous year’s reporting date 28.8%).

Dividend

The Board of Directors proposes to shareholders the distribution of a dividend of CHF 2.00 per share for 2024 based on the positive free cash flow of CHF 14.1 million and the improved equity ratio of 33.7%. This corresponds to a payout ratio of 85.8%.

Sustainability

Rieter has a clearly defined sustainability strategy that is closely linked to the Group strategy. Through the Science Based Targets initiative, Rieter made a commitment in 2024 to define company-wide emission reduction targets for the year 2040, which are consistent with scientifically-based net-zero goals. In this way, the Rieter Group takes responsibility for its own impact while supporting its customers on their sustainability journey. In the 2024 Annual Report, the report on non-financial matters shows the progress Rieter has made in the areas of environmental, social and corporate governance.

Outlook 2025

Rieter expects a challenging first half in 2025 with regard to sales volume and a stronger second half-year depending on the further market recovery. As a consequence, Rieter anticipates a sales volume at the previous year’s level for the full year 2025. Despite this exceptionally low sales level, Rieter anticipates a positive EBIT margin between 0% to 4% for the year 2025.