#Techtextil 2019

Toray presents flame-shielding fabric GULFENG at Techtextil in Frankfurt

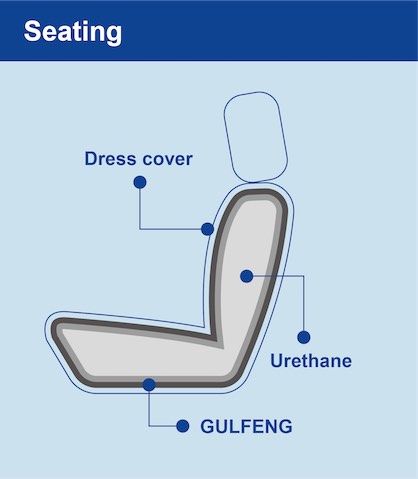

Ranging from thin paper to thick felt, the material works as a fire blocker in electronic devices, seat cushions, and other application scenarios.

Reliable fire protection, soft to the touch

Compared to other flame-retardant materials that are made of glass-fiber, m- and p-aramid or Ox-PAN felt, GULFENG is lighter, thinner, and more flexible. The paper variant is no thicker than 0,06 mm and weighs 60 g/m² – it looks and feels just like regular paper. The material can also be knitted or woven into a soft fabric or felted into flexible mats. This versatility means that the material can be used for batteries, bedding and bus seats alike.

Despite its thinness, GULFENG loses none of its flame-retardant properties and serves as a fire barrier. Flames are stopped from spreading and igniting surrounding combustible materials. This is achieved by combining thermoplastic polyphenylene sulfide (PPS) with oxidized polyacrylonitrile (OX-PAN) fibers. When heated by a flame to 285°C, the PPS fibers start to melt and build a membrane around the non-melting Ox-PAN fibers. These absorb heat and start to carbonize, thus creating a closed barrier against flames

A history of material innovation

In developing the GULFENG material, Toray was able to draw on its longtime experience with both PPS and carbon fiber technologies – it seemed only natural to combine both into one fire-blocking material. Starting with GULFENG paper, Toray engineers then worked to expand the use cases and textile structures to serve different customer needs. Currently, the company is also exploring GULFENG leather, a flame-retardant base material for synthetic leather. It eliminates the need for an intermediate layer of flame-shielding material and could make seating cushions even thinner and thus more comfortable.

Toray’s wide product portfolio will be on display at Techtextil. In Hall 4.2, booth D48, the company is also exhibiting a number of other technical textiles, including the Axtar polyester non-woven fabric and a LCP fiber named Siveras.