#Yarn & Fiber

Toray develops durable reverse osmosis membrane

The new membrane offers double the resistance to cleaning chemicals of conventional counterparts. This reduces performance degradation from membrane wear and simplifies operational management, halving replacement frequencies and shrinking the product’s carbon footprint.

The company is preparing to mass produce this membrane and launch it in the rapidly expanding Chinese market in the first half of 2024. It looks to develop products with the new membrane for the global market including Japan.

The broad applications of RO membranes include desalinating seawater and river water, reusing wastewater, and producing drinking water as a technology to ensure sustainable water sources. Reusing wastewater entails treating water of diverse quality levels with RO membranes. The downside is that an increased reliance on cleaning chemicals to purge contaminants on the membrane surface to maintain their operational efficiency deforms their pores, diminishing removal performance. This has spurred demand for more resilient membranes.

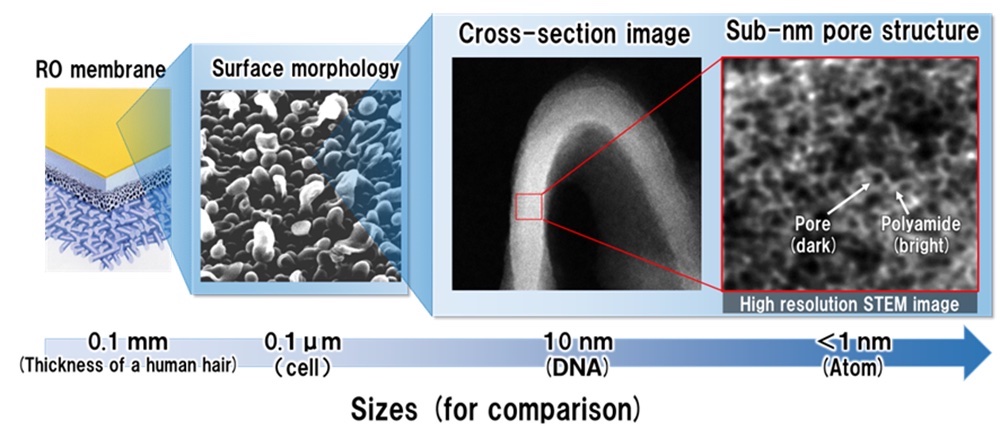

The company combined a Toray Research Center-developed scanning transmission electron microscopy (glossary note 2) technology and a digital data analysis technique to quantitatively analyze the pore of the separation layer of RO membranes, which is smaller than one nanometer (a billionth of a meter) in diameter. Toray drew on the analysis to identify a substructure that helps enhance pore structure stability when in contact with cleaning chemicals. It innovated a manufacturing process to design a new polymer structure, thus creating a RO membrane that delivers a stable pore structure.

Toray tested its new RO membrane at a wastewater reuse plant to simulate harsh chemical cleaning conditions. The membrane proved effective in reducing deterioration in the quality of obtained water. This membrane should deliver an extended lifespan in such applications in sewage treatment and wastewater reuse facilities of chemical, steel, and dyeing plants requiring frequent chemical cleaning and in attaining zero liquid discharge (glossary note 3). This could potentially slashes carbon dioxide emissions by 50% associated with replacing and disposing of membranes. The company will establish a mass production system to supply products meeting customer needs.

Toray will keep leveraging its core technologies of synthetic organic and polymer chemistry, biotechnology, and nanotechnology to innovate materials in keeping with its commitment to delivering new value and contributing to social progress.

Glossary

1. Reverse osmosis membranes

When concentrated and dilute solutions are in contact through a semi permeable membrane, the water moves from a dilute to concentrated solution as a result of osmotic pressure because the concentrations differ. Under a pressure exceeding that of osmotic pressure on the concentrated aqueous solution, water passes through the semi permeable membrane and goes to the dilute solution. Membrane separation employing this phenomenon is called reverse osmosis. Reverse osmosis membranes remove sodium, calcium, and other metal ions, chlorine and sulfate ions and other anions, and such low molecular organic compounds as pesticides.

2. Scanning transmission electron microscopy

See Japanese-language news release that Toray Research Center issued on February 24, 2023, titled, Toray Research Center Launches Contract Analysis Service for Advanced Imaging Techniques Employing Transmission Electron Microscope

3. Zero liquid discharge

This is a framework for water reuse by ultimately discharging only solid waste with concentrators and crystallizers after RO membrane and other treatment, eliminating environmental or sewage releases of wastewater from factories and other facilities.