Nonwovens / Technical Textiles

Focus on the entire process chain in nonwovens manufacturing

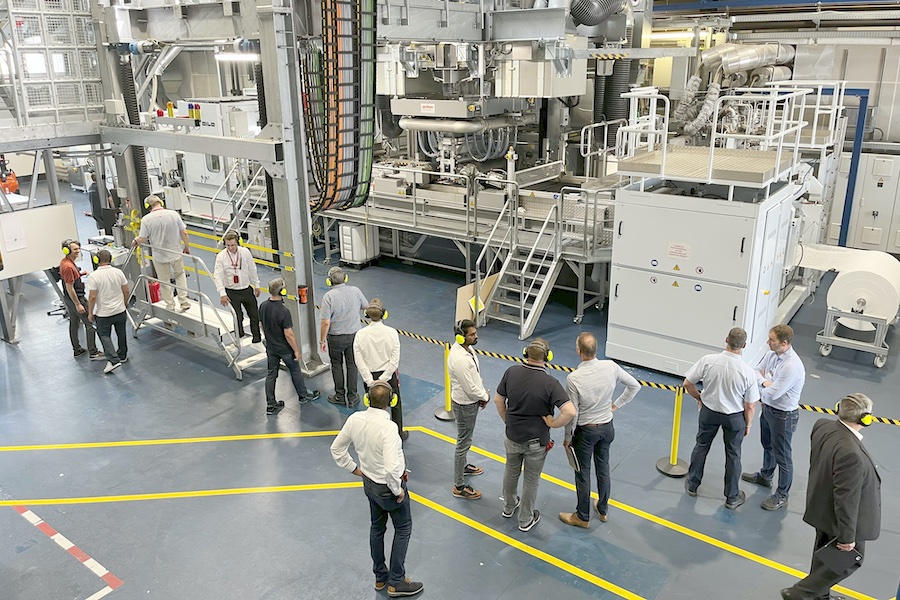

Open House with partners

Around 50 guests took advantage of the opportunity to attend numerous presentations and see various spunbond and meltblown technologies in action at the Neumünster Technology Center. In addition to the patented and (multiple) award-winning solution for producing charged meltblown nonwovens using water atomization, demonstrated using the example of a process with PLA, the spunbond processes for producing BiCo PET/CoPET and PP geotextiles were also presented.

Presentations along the process chain

Eight partner companies from all stages of the nonwovens manufacturing process made an indispensable contribution: Weko presented its solutions for spin finish applications. Dilo presented machine concepts and innovations in the field of needling technology. Brückner provided information on thermoprocessing lines for finishing nonwovens, while Mahlo focused on online measurement systems. Oerlikon Barmag provided an insight into its diverse range of pumps, which are also indispensable in the nonwoven process. In addition to the presentation on the Oerlikon Nonwoven Meltblown system, TotalEnergies Corbion contributed to the topic of sustainable raw materials with a presentation on Luminy® PLA.

Somatec rounded off the event with a presentation on the world of winding, and Comerio Ercole showcased innovations in the field of calender solutions. “A successful event here in Neumünster at our nonwovens competence center,” agreed Andreas Frisch and Ingo Mählmann, who are responsible for the business unit. The overall approach and the various process demonstrations in the technical center were well received. “We don't want to deliver isolated solutions, but rather solutions that are coordinated with our customers and the upstream and downstream process stages,” said Andreas Frisch, explaining the format. He added: “Experiencing the technology live and in color is extremely helpful for understanding our solutions.”