#Research & Development

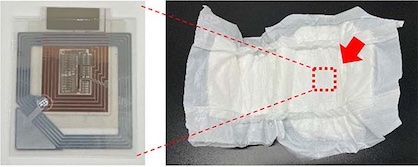

Toray develops diaper-embedded urination sensor tapping on-film semiconductor circuit technology

The company recently tested the capabilities of automatic urine-detecting diapers worn by patients at a nursing home. It intends to further evaluate performance with larger groups of individuals, with a view to commercializing the sensor during the fiscal year ending March 2026.

In Japan, the number of individuals needing eldercare is increasing each year as the population ages. At the same time, labor shortages in a shrinking workforce will likely amplify caregiver responsibilities in nursing homes, highlighting the need to tackle this societal challenge.

Toray previously used its proprietary semiconductive carbon nanotubes composites technology to create a sensor integrated into a general-purpose film to detect moisture. It confirmed that the sensor could operate wirelessly. Embedding the sensor into a diaper made wireless communication unfeasible, however, owing to moisture from the human body and urine.

The company addressed that challenge by implementing moisture-resistant wireless communication technique. It also explored a sensor configuration that is less vulnerable to moisture, confirming its effectiveness with input from nursing home residents. In developing the sensor, Toray collaborated with Koyo Co., Ltd., which manufactures and sells disposable diapers for adults. The Sanko Welfare Association helped to verify the sensor’s performance.

The film-based sensor conforms to diaper contours, eliminating discomfort for wearers. Formed directly on the film, the semiconductor circuit prevents peeling, unlike silicon counterparts. Caregivers can easily use a diaper in which the sensor is pre-embedded and dispose of it without any special procedures, similar to a regular diaper. This innovation allows caregivers to effortlessly monitor changing times with a PC, smartphone, or tablet, reducing workloads and optimizing diaper changes, thus decreasing diaper consumption.

Another pivotal benefit of the sensor is that its real-time urination detection enables caregivers to gather data and accurately predict urination timing. They can thus efficiently guide individuals to restrooms when necessary, and thereby the individuals are expected to go to restrooms by themselves.

Technology to form semiconductor circuits directly on film by printing technology provides significant design flexibility and allows small-lot production with minimal expenses. Toray has already set up a pilot line at its Shiga Plant to manufacture printed semiconductors. It aims to collaborate with partners to promptly commercialize a urination detection system leveraging its sensor technology.

The company intends to draw on the characteristics of film-based printed semiconductors to draw on such technologies as radio frequency identification to optimize logistics site operations and address labor shortages. It will additionally implement authentication applications to combat counterfeit products and foster a safer and more secure society.

Toray will continue to develop revolutionary materials that resolve a range of social issues in keeping with its corporate philosophy of contributing to society through the creation of new value with innovative ideas, technologies and products.