#Weaving

The creative luxury of Lanificio Cerruti selects the pioneering weaving technology of Itema

Collaboration agreement between the two excellences of Made in Italy in the name of sustainable innovation

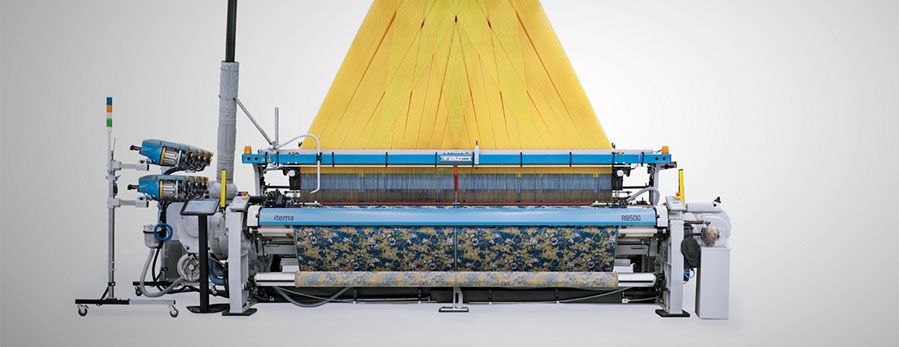

After a strategic study based on a careful market and competitors’ assessment, Lanificio Cerruti identified the Itema rapier weaving machine as the best technology to meet its demanding needs and Itema as the ideal candidate to forge a partnership grounded on shared values. The Itema rapier R9500² ensures to Lanificio Cerruti the highest sustainability levels in three different fields:

- environmental, as it is designed to reduce energy consumption and waste of raw materials;

- social, thanks to the ergonomic features that simplify and protect weavers;

- economic, due to the delicate treatment of the yarns which leads to raw materials saving and quality improvement; furthermore, the remote monitoring allows to minimize interruptions and failures. With this agreement Lanificio Cerruti and Itema, excellences of Made in Italy respectively in the fashion and in the weaving machinery industries, start a cooperation based on the common orientation towards an increasingly sustainable innovation, meant to generate value while respecting the environment and people.

"Lanificio F.lli Cerruti joins with great satisfaction a partner of excellence as Itema to undertake a path that will help us to further enhance the concept of creative luxury, so inherent in the DNA of our company" - commented Filippo Vadda, President and CEO of Lanificio Cerruti - "This partnership is the evidence of our strong commitment to an increasingly positive impact on the planet and on future generations - since at Lanificio Cerruti sustainability means looking ahead using the best available technology".

“We are proud to work with Lanificio Cerruti. It is not just a technological partnership, but the beginning of a co-development journey that will allow us to design and implement solutions of great value", added Ugo Ghilardi, CEO of the Itema Group. "We firmly believe that together we will give prestige to the Made in Italy creativity and innovation, which are admired all over the world".

The new Itema weaving machines will be installed in the Biella plant of Lanificio Cerruti starting from March 2022.