#Weaving

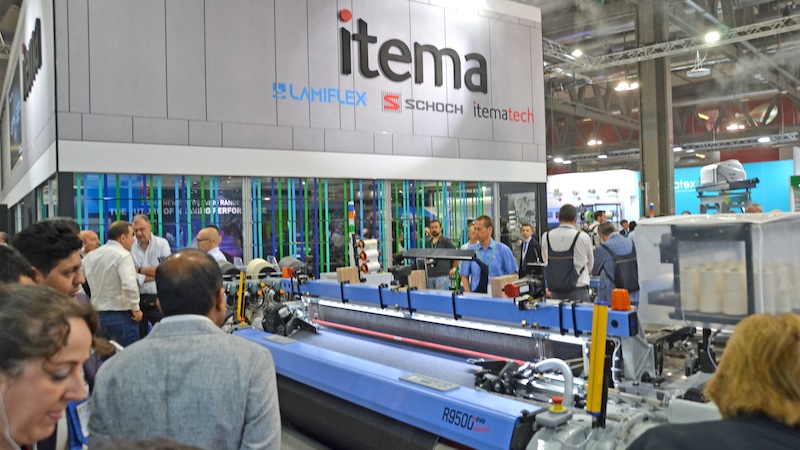

Itema completes the acquisition of Schoch & Co Srl

Schoch has been founded by Alfredo Schoch in 1907 in Ranica, Bergamo Province, and since then manufactures high quality accessories for the textile industry. Son of a Swiss reeds manufacturer, Alfredo Schoch sets up his business in Italy and carries on the family’s entrepreneurial vocation.

Over the years, Schoch installs in its plants the most advanced manufacturing technologies to constantly ensure its products renowned superior performances.

In 2019, with the entry into Itema Group, Schoch moved the Italian site from Ranica to Colzate, at the Itema headquarters and could count on a solid and well-structured organization, dedicated to satisfying even the most demanding customers' requests. In addition to the Italian plant, Schoch also has a production site in India with 100 employees.

Ugo Ghilardi, CEO of Itema Group, commented: “With this transaction, we completed the acquisition process of Schoch & Co. As done in 2021 with Lamiflex, Itema aims to integrate the human and industrial capital of the Group’s companies with the ultimate goal of maximizing collaboration and results, both in terms of product development and new markets.”