#Weaving

Stäubli at Domotex asia/CHINAFLOOR 2025

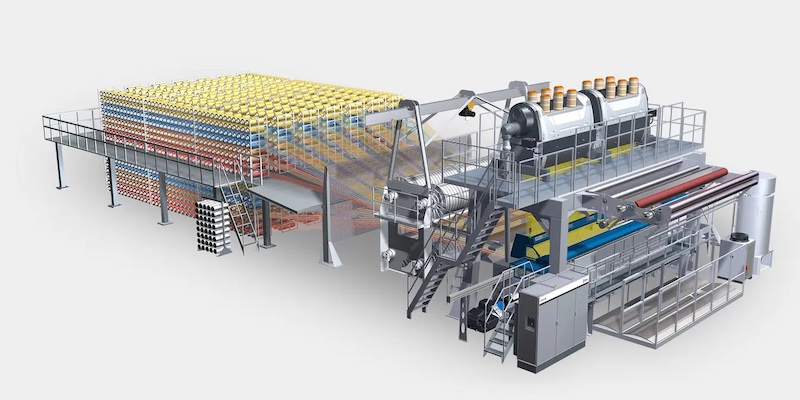

The ALPHA 580 UNIVERSAL stands out with a diverse range of design options. Visitors will see rugs made with this new weaving system and a demonstration of a wide variety of binding techniques:

+ cut pile and flat weave

+ pattern on the ground

+ weft patterning

+ high pile

Besides the compactness of the ALPHA 580 UNIVERSAL, carpet mills especially appreciate the easy operation and high operational reliability of this machine.

Visit Stäubli at Domotex Asia Chinafloor: The entire team looks forward to seeing you at booth C32 NEEC Shanghai in Hall 6.1.

Visitors will learn about the many advantages of the ALPHA 580 UNIVERSAL carpet weaving machine, including the new shedding components for pile and basic weaves. In addition to the technical benefits, Stäubli offers a full range of services, including practical advice prior to any purchase, training before weaving, support services even many years after the purchase, and much more.