#ITMA Asia + CITME 2024

Itema exhibits at ITMA ASIA + CITME 2024 and reaffirms its commitment to provide Chinese and Asian markets with high-performances weaving solutions

The past, present and future of weaving on display

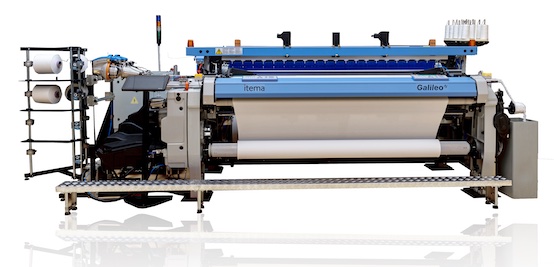

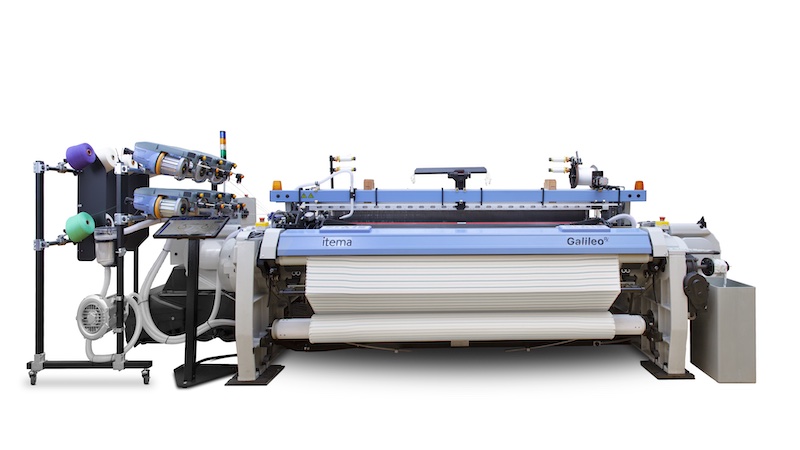

Born from the legacy of the most successful high-end rapier weaving machine assembled in China, the Itema R9000 and R9000-2, the GalileoRX features technological and design advancements to fully meet the needs of the market, reaching unbeatable levels in terms of performances, textile mastery and eco-efficiency. Launched in 2022 to address the specific needs of the Chinese and Asian textile markets, the Itema GalileoRX has rapidly gained recognition for its ability to weave a wide range of fabrics with superior quality and precision.

The GalileoRX on show at the Itema booth – in 2300 mm weaving width - will weave an Apparel style and will be equipped with two of the latest Itema innovations: the New Generatione Machine Console, with a 15.6” wide touch, full glass, capacitive display, and the iSAVER®fancy. Based on the mechatronic technology of iSAVER®eco, iSAVER®fancy is available up to 6 weft colors and allows to eliminate the waste selvedge on the left-hand side of the rapier machine thus providing substantial costs saving and significant contribution to sustainable weaving by reducing raw materials and resources waste.

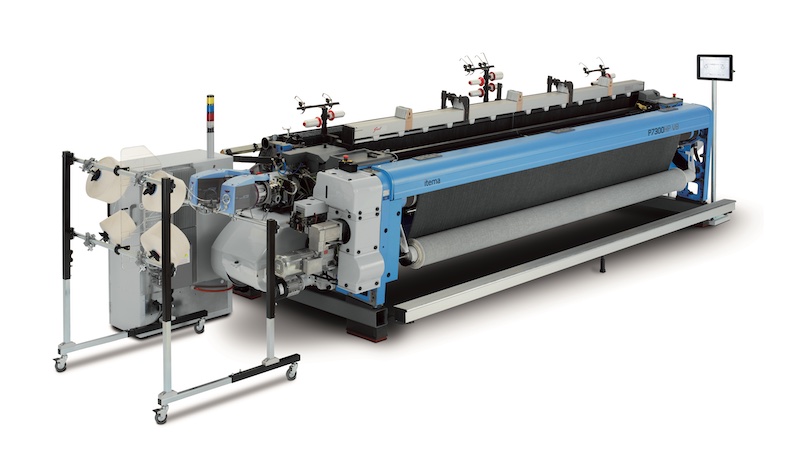

Moreover, in the year of its 70th anniversary, the legendary projectile weaving machine makes its grand return to an international trade fair.

The Itema projectile P7300HP V8, in 3900 mm weaving width, will weave a Denim style. Renowned for its unbeatable reliability and high productivity, the P7300HP V8 ensures excellent fabric quality even for heavy- duty textiles such as denim and technical fabrics. Itema is the only weaving machine manufacturer that offers projectile weaving technology - and continues to push the boundaries of projectile weft insertion technology, which still remains the best weaving machine for specific applications.

This year also marks a milestone for projectile weaving technology as we celebrate the 70th anniversary of the official unveiling of the TW11, the first projectile weaving machine, which was presented at the Mustermesse in Basel in 1954. The TW11 revolutionized the weaving industry with its unique weft insertion system and ability to efficiently produce extra-wide and heavy fabrics, laying the groundwork for subsequent generations of projectile looms like today’s P7300HP V8.

Additional machines displayed at partner booths

Guests will also have the opportunity to see eight additional Itema rapier weaving machines showcased at our partner booths, including Huzhou Hyundai (Julibao) at Hall 3 – C08, Lilai (Hall 3 – Booth A38), Tongxiang (Hall 3 – Booth E07), Changfang (Hall 3 – B35), Huling and Song&Song (Hall 3 – A67).

Itema Group’s complete offer of weaving solutions

During their visit to ITMA ASIA + CITME 2024, visitors will be able to learn more about the full range of weaving solutions offered by Itema Group:

• HelloItema, the Itema customer portal – offering a comprehensive set of digital functionalities and smart solutions and designed to make customers' working lives easier and add value to their investment. Accessible via browser or app from any device – and directly from the machine console on new generation Itema machines – users can order original spare parts, check order status in real- time, open service tickets, and access relevant machine documentation.

• The full range of OEM spare parts and the latest solutions for upgrading existing Itema looms, as well as previous brands such as Sulzer, Somet, and Vamatex.

• Lamiflex, part of the Itema Group, will showcase advanced weaving accessories, including rapier tapes and sprocket wheels.

Visitors to ITMA ASIA + CITME 2024 will have the chance to experience firsthand how Itema continues to provide state-of-the-art solutions tailored to the evolving needs of worldwide textile industries. To learn more, visit the Itema Group Booth in Hall 3 – Booth C11.