#Spinning

55 years of collaboration: Parkdale and Trützschler’s ongoing partnership

For over 108 years, Parkdale has proven to be a reliable full-service yarn supplier. Operation began at its first facility in Gastonia, North Carolina, producing 425 tons of thread yarn per year. Since then, it has grown into the largest consumer of cotton in the US. Parkdale produces more than 8,000 tons per week at 21 manufacturing sites in the US, Mexico, Central America and South America. It supplies many industries worldwide with spun yarns consisting of fiber blends including cotton, polyester, rayon, nylon and acrylic.

Trützschler entered the US market in 1969 and almost immediately engaged in close cooperation with Parkdale. Together, the two companies have successfully identified and adapted to several big transformations within the textile industry. Those achievements are evidence of the shared focus on exploring new technologies and continuously improving production processes. As the latest step forward in this pioneering partnership, Parkdale recently ordered 34 carding machines equipped with SUPERTIP wires from Trützschler on the licker-in, cylinder and doffer roller.

Taking clothings to the next level

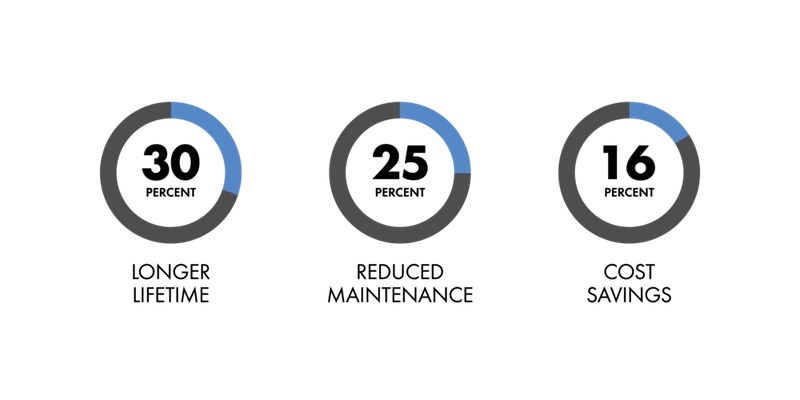

SUPERTIP wires are the newest innovations in Trützschler’s range of clothings. Parkdale selected these wires because they achieve big contributions to quality and precision. Specifically, the customer values the outstanding durability of SUPERTIP wires. All SUPERTIP offer a service lifetime that is up to 30 % longer than conventional solutions, which cuts maintenance requirements by up to 25 %. In this way, Parkdale can now minimize service disruptions and ensure smoother processes – with lower costs.

Parkdale uses a variety of SUPERTIP wires for its uniquely diverse range of applications and process parameters. In total, more than 300 versions of the SUPERTIP clothings are available – and our teams are constantly expanding that portfolio. This wide range of innovations makes certain that we always have the perfect wire for each customer’s unique needs. It also eliminates the need to grind newly fitted clothings, which further extends intervals between maintenance tasks.

“Parkdale has trusted the Trützschler Card Clothing (TCC) team to be a full-service provider for our card clothing needs. They have exceeded our expectations for quality and performance throughout our entire manufacturing network, spanning throughout the Americas. TCC continually works with our team members, looking for innovative strategies to delight our customers,” says Charles Heilig, President and CEO of Parkdale Textile Division.

Parts and people are always available

Parkdale’s recent order for SUPERTIP card clothings is an important milestone in a partnership that now extends for over half a century. The customer can rely on fast availability of parts including stationary and revolving flats, licker-ins and more. And our technical specialists are always ready to visit Parkdale’s sites and conduct full-service maintenance in line with the highest standards.

“We’re incredibly proud of our longstanding partnership with this well-known industry leader,” says Greg Duncan, Vice President Spinning Machine Sales American Trützschler (ATR). “Our companies have collaborated for more than five decades. Personally, I’ve worked with Parkdale for over thirty years. I know how much Parkdale values the full maintenance service that our mechanics, engineers and technologists provide – as well as our pioneering solutions for card clothing.”

Benefits of SUPERTIP

SUPERTIP stands for enormous durability, great versatility and the highest precision. These benefits have been achieved through a new, unique manufacturing process that builds on TCC’s long technological expertise in the market.