#Weaving

From the Venus flytrap to foldable aircraft wings: Peter Dornier Foundation Prize 2025 honours bionic research on 3D weaving technology

Longer aircraft wings can increase the efficiency and sustainability of commercial airplanes because they reduce aerodynamic drag and thus lower fuel consumption. The problem: aircraft with long wings encounter spatial limitations at airports, for example on taxiways or at gates. ‘That's why we simply fold up the wingtips,’ says Dr Patrick Meyer, a research assistant at the Institute of Mechanics and Adaptronics at TU Braunschweig until July and now a development engineer at Lufthansa Technik. The idea of foldable wingtips is not new: Boeing, for example, has opted for foldable wings on the ground for its latest model, the 777X. Airbus is also working on movable wingtips. According to Meyer, however, there is even more potential in the concept of foldable wingtips: ‘By using pressure-controlled actuators with customisable mechanical properties, wingtips could become multifunctional control surfaces.’ The inspiration for this concept came from nature.

Carnivorous plant serves as a role model

In principle, the Venus flytrap works like a hydraulic system: as soon as an insect falls into the trap, the plant closes its leaves in a fraction of a second by specifically changing the pressure in its cell walls. These so-called nastic movements form the basis of ‘PACS’ (Pressure-Actuated Cellular Structures) – a still young technology that is essentially based on research work at the TU Braunschweig and the German Aerospace Centre. ‘In principle, PACS is a technical replica of the mechanics of the Venus flytrap and has precisely the properties that robust yet easily manoeuvrable wingtips need.’ To implement the PACS concept for his idea of controllable wingtips, Meyer teamed up with textile researcher Dr Michael Vorhof from the Institute of Textile Machinery and High Performance Materials Technology at TU Dresden. ‘Plants are made of fibres – if you want to copy them, you also have to copy their complex, fibre-based structure,’ explains Vorhof.

3D weaving paves the way for sustainable aviation

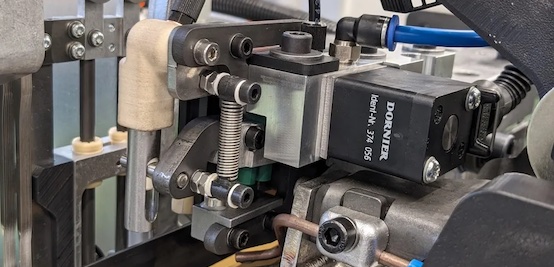

In order to transfer the complex structure and mechanics of the Venus flytrap into a woven and movable wingtip that can be bent by changing the pressure, Vorhof used a weaving machine from machine and plant manufacturer Lindauer DORNIER GmbH, whose 75th anniversary is being celebrated this year. 'The robust design, the composite-compatible layout and the high precision of the DORNIER weaving machine were crucial in helping us to implement the complex fibre structure required for PACS,' says Vorhof. The woven semi-finished products consist of glass fibre and polyamide threads and are melted in a thermo press to form the fibre composite plastic component. ‘This is significantly cheaper than using an autoclave,’ says Vorhof. Aeroelastic analyses on the model of a Cessna Citation show: The woven lightweight wingtip, inspired by nature, is able to bear the loads exerted during a flight and can be moved up and down in seconds.

Interdisciplinary achievement honoured

For their joint research work as part of their dissertations, the two doctoral students from aerospace and textile technology were honoured in July with the Peter Dornier Foundation Prize 2025, which is endowed with 5,000 euros each. At the award ceremony at the Lindauer DORNIER Weaving Technology Centre, the trustees Dr Bernd Sträter and Dr Adnan Wahhoud acknowledged the special significance of the work: ‘These are two excellent dissertations that use well-known process parameters of modern 3D weaving technology from DORNIER to develop practical applications related to current advances in aircraft construction to make aviation more sustainable.’ Peter D. Dornier, son of the founder and responsible for the foundation prize in the advisory board of the Peter Dornier Foundation, emphasised in his speech to about 120 guests: 'My father would have been delighted with this interdisciplinary research work, because it builds on two of his core areas of interest: aircraft construction and textile technology. With his pioneering ideas, the founder of DORNIER has shaped both areas – for example, by developing the positively controlled rapier weaving machine and supplying it to French glass and carbon weavers, who used it to produce fibre composite aircraft components already at an early stage. The foundations for the Composite Systems division, which was established in 2014, were thus laid back in the 1970s; today, this division includes, among other things, 3D weaving machines for the production of 3D carbon fibre fabrics for turbine blades, explained Dornier, longstanding Managing Director and now Chairman of the Supervisory Board of Lindauer DORNIER. He also praised the interdisciplinary cooperation between the two institutes in particular: ‘In Germany, several chairs often conduct parallel research on highly interesting topics – this cooperation is exemplary of how two different institutes can work together systematically and successfully on a future-oriented project,’ said Dornier.

The future of foldable wings

The two young researchers expressed their appreciation at the award ceremony in Lindau: ‘It is a great honour for us to be awarded the Peter Dornier Foundation Prize, as it combines textile innovations with aviation and thus recognises interdisciplinary research such as ours,’ said Meyer, who undertook research flights in a Dornier Do 228 as part of his studies. In order to further develop the concept, the prize winners' institutes are planning follow-up projects and the construction of the first prototypes. “If everything goes well, our technology could be used in the second next generation of aircraft,” the two prize winners cautiously anticipate.

The Peter Dornier Foundation Prize

The idea of the Peter Dornier Foundation Prize goes back to Peter Dornier (1917-2002), the founder of Lindauer DORNIER GmbH. Since 2021, the prize has been awarded to young people for outstanding scientific work in the fields of textile, film and composite technology as well as aviation. Funding medical research is just as much a part of the foundation's purpose as supporting hospices for a self-determined and dignified life until the end.