#Research & Development

STFI Theme Day: Advancing technologies for a circular textile economy

Challenges on the path to a circular textile economy are diverse and complex. They span across material research, processing and treatment technologies, product design, usage and care, business models, and even policy measures, which play a crucial role in incentivizing transformation. Given the current single-digit recycling rates, there's a considerable journey ahead. However, recent advancements in textile waste collection, sorting, and processing demonstrate that transformative momentum is building. Solutions must be as diverse as textile product designs themselves, with a circular economy emerging as a culture that involves us all.

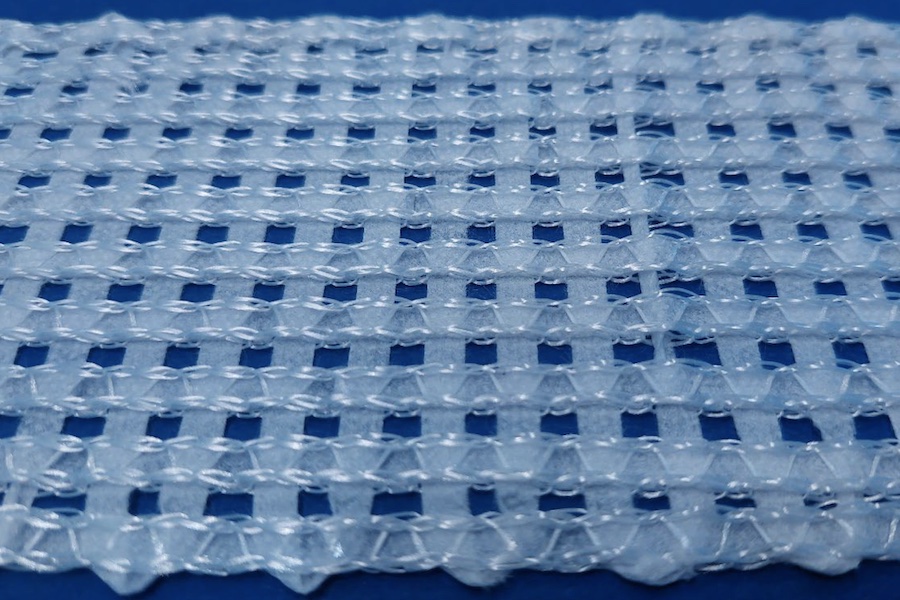

For over 30 years, STFI has served as an innovation partner and service provider to a wide array of sectors within the textile industry. With the development of the Center for Textile Sustainability and the addition of a wetlaid nonwovens line, STFI has further advanced its expertise in nonwoven innovation, textile recycling, and testing services.

Event Program:

09:00 a.m. – 10:00 a.m.

Registration at the Center for Textile Sustainability

Welcome Address: Dr. Yvette Dietzel, Head of Research at STFI

Circular Textile Economy – Topics, Trends, and Perspectives: Johannes Leis, M. Sc., STFI

Are Natural Fibers a Mega Trend? Dr. Jörg Morgner, Temafa Maschinenfabrik GmbH

TBA – Caspar Böhme, Sumo GmbH

Technologies for Textile Circular Economy at STFI: Johannes Leis, M. Sc. & Dipl.-Ing./Dipl.-WI Ina Sigmund, STFI

12:00 p.m. – 1:30 p.m.

Lunch and Tours of facilities, including the Textile Recycling Center, Spinning Mill, Wetlaid Technology Centre, and Laser Technology Centre

End of Event and Commencement of STFI General Meeting

Registration Details:

Participants may register until November 25, 2020, at

https://www.stfi.de/thementag

Join STFI as they want to explore and shape the future of a circular textile economy through innovation, collaboration, and cutting-edge technology at STFI’s Theme Day.