#Research & Development

Kendyr as a climate-friendly cotton alternative: STFI explores new value chains for salinised land in Central Asia

From wild growth to textile process chain

During the project period, only wild-harvested kendyr stalks were available. These were harvested locally and mechanically opened in Germany. The fibres were almost completely freed from shives, shortened to cotton staple length, and degummed to achieve a fineness of 40?dtex. Subsequent carding reduced the fineness to 5.6?dtex—comparable to Chinese hemp and closer to cotton than any other regionally available bast fibre. Kendyr also has a natural, slightly rust-red colour, similar to colour-grown cotton.

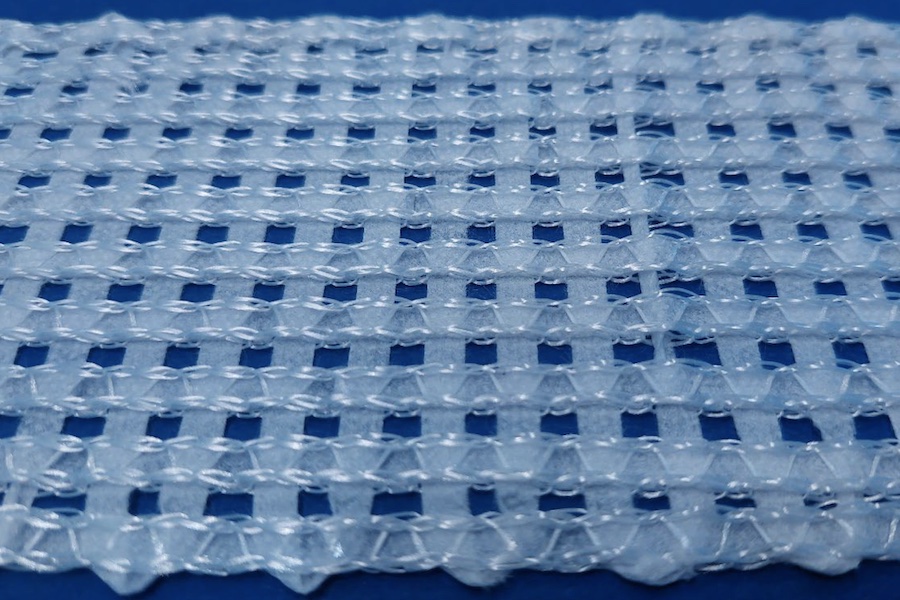

The refined fibre was successfully spun at production scale into a 30?tex (Nm?34) ring yarn blended with 70% cotton and processed into lightweight knitted fabrics (110–140?g/m²).

Research and industry partners

In addition to STFI, project partners included Martin Luther University Halle-Wittenberg, the Leibniz Institute for Agricultural Engineering and Bioeconomy (ATB), HANFFASER Uckermark eG, the hessnatur Foundation, Sachsen-Leinen e.V., and international partners from Central Asia.