#Research & Development

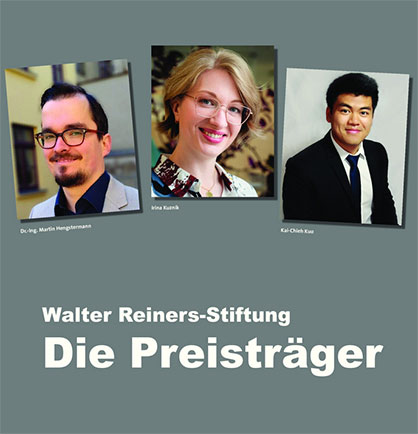

ITA PhD student Kai-Chieh Kuo was awarded Best Master’s Thesis Award of Walter Reiners-Stiftung (Foundation)

Significant advance in aortic prostheses through high-density, thin-walled tubular woven fabric

Minimally invasive endovascular aortic repair (EVAR) with textile stent-graft systems is nowadays a clinically established therapy procedure for the treatment of abdominal aortic aneurysms (AAA) – pathological bulges of the aorta. Due to the thick profile of the folded stent graft systems, there is currently a high risk of injuring narrowed or highly angulated access vessels from the inside during implantation. Stent graft systems with smaller profiles could provide an improvement, which could overcome complicated access routes through a lower bending stiffness. One possible approach for reducing the system profiles is the use of thin-walled tubular woven fabrics made of ultrafine multifilament yarns (?20 dtex) as graft material.

Up to now, it has not been possible to process the fine yarns with the required high thread density (>200 threads/cm) and the available weaving technology in order to guarantee sufficient tightness against blood.

In his master's thesis, Kai-Chieh Kuo made high-density tubular weaving of ultra-fine filament yarns possible for the first time by means of suitable modifications to a shuttle loom as well as adaptations in the weaving preparation. In particular, he developed a new innovative reed technology that reduces warp thread friction during the shedding process and thus improves the process stability of the dense tube weaving process of fine yarns.

With the help of the process modification, it was then possible to produce high-density, thin-walled tubular woven fabrics, which were positively evaluated with regard to their suitability for a stent graft. Above all the potential of these tubular fabrics lies in their extremely thin-walled fabric profile, which seals well against blood. By using these new types of tubular fabrics as graft material for stent grafts, the system profile of the folded stent graft system can be reduced without having to compromise the blood tightness of the implant. The technology developed by Mr Kuo is not only applicable to stent graft systems, but also offers great possibilities for use in all other endovascular implants such as trans catheter heart valves, covered stents and small-lumen vascular prostheses.

Through its Walter Reiners-Stiftung (Foundation), the VDMA Textile Machinery Association is actively involved in promoting young engineers. Every year, the Foundation awards prizes for the best dissertation, diploma or master's thesis and the creativity prize for the cleverest student research project. In 2020 and 2018, ITA graduates have already been awarded promotional prizes from each category.