#Research & Development

Vacuum insulation panels rethought - Adjustable, tailored to needs, flexible

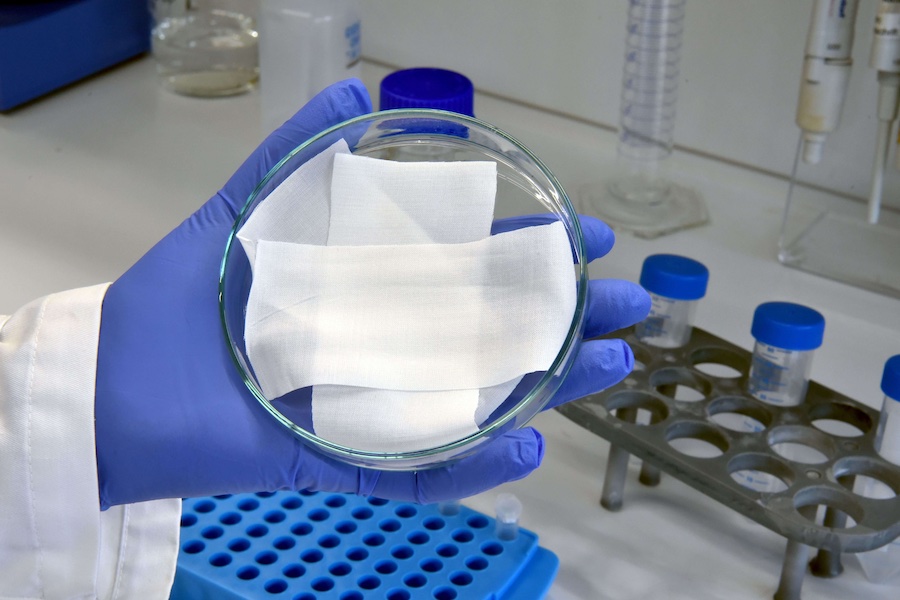

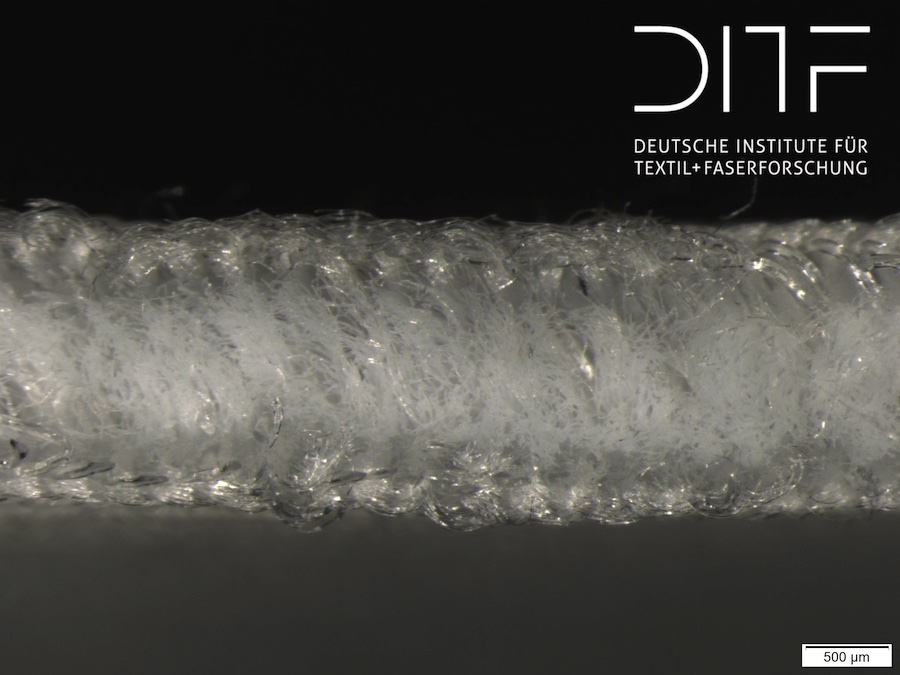

The research project is developing adaptable insulation elements based on the Knudsen effect. The Knudsen effect describes the change in the thermal conductivity of porous structures with the prevailing gas pressure in the pore space. If there is a vacuum in the pore space, the thermal conductivity is low; if the pressure increases, the thermal conductivity also increases. In order to use the principle in an adjustable insulation element, the highest possible switching factor between the two states is required. To achieve this, the pore system and gas pressure range must be optimally matched. In the adaptable insulation panel, the pore system consists of a spacer fabric that is being developed at the DITF. A key challenge here is the compressive strength of the filling core, which must only allow minimal deformation at a surface pressure of 10 N/cm2 imprinted by a fine vacuum.

The research team at the Technology Center Knitting Technique at DITF has developed the corresponding pressure-resistant structures. Their pore size will be optimized in the next steps by inserting textured yarns into the pole thread space. The basic thermal conductivity of the structure should be increased as little as possible. With the knitted structures in the panel, a switching factor, i.e. the ratio of maximum to minimum thermal conductivity achieved, of 5 has already been demonstrated. Current work involves optimizing the spacer structures and setting up a demonstrator.

In the joint project, the Institute of Technical Thermodynamics at the German Aerospace Center (DLR) in Stuttgart is developing a thermochemical reactor component that enables precise and energy-efficient gas pressure adjustment in the vacuum insulation panel. Metal hydride-hydrogen reaction systems are used, which allow the gas pressure in the insulation panel to be set through temperature control.

The Institute for Building Energetics, Thermal Engineering and Energy Storage (IGTE) at the University of Stuttgart is investigating the integration possibilities of the panels in the wall composite using simulations and experiments. The thermal-energetic simulations make it possible to assess the energy-saving potential of the technology in different scenarios and under different boundary conditions. A demonstrator is used to test the adaptable thermal insulation in an application-oriented manner.

The ReVaD project (development of adaptable vacuum insulation elements for the needs-based adaptation of heat transfer in building envelopes and structures as well as the thermal activation of storage masses) is funded by the Federal Ministry of Economics and Energy as part of joint industrial research (IGF) (FKZ: 22617 N).