#Research & Development

Researchers develop living material from fungi

Sustainably produced, biodegradable materials are an important focus of modern materials science. However, when working natural materials such as cellulose, lignin or chitin, researchers face a trade-off. Although these substances are biodegradable in their pure form, they are often not ideal when it comes to performance. Chemical processing steps can be used to make them stronger, more resistant or more supple – but in doing so, their sustainability is often compromised.

Empa researchers from the Cellulose and Wood Materials laboratory have now developed a bio-based material that cleverly avoids this compromise. Not only is it completely biodegradable, it is also tear-resistant and has versatile functional properties. All this with minimal processing steps and without chemicals – you can even eat it. Its secret: It's alive.

Optimized by nature

As the basis for their novel material, the researchers used the mycelium of the split-gill mushroom, a widespread edible fungus that grows on dead wood. Mycelia are root-like filamentous fungal structures that are already being actively researched as potential sources of materials. Normally, the mycelial fibers – known as hyphae – are cleaned and, if necessary, chemically processed, which brings about the above-mentioned trade-off between performance and sustainability.

The Empa researchers chose a different approach. Instead of treating the mycelium, they use it as a whole. As it grows, the fungus not only forms hyphae, but also a so-called extracellular matrix: a network of various fiber-like macromolecules, proteins and other biological substances that the living cells secrete. “The fungus uses this extracellular matrix to give itself structure and other functional properties. Why shouldn't we do the same?” explains Empa researcher Ashutosh Sinha. “Nature has already developed an optimized system,” adds Gustav Nyström, head of the Cellulose and Wood Materials lab.

With a bit of additional optimization, the researchers gave nature a helping hand. From the enormous genetic diversity of the split-gill, they selected a strain that produces particularly high levels of two specific macromolecules: the long-chain polysaccharide schizophyllan and the soap-like protein hydrophobin. Due to their structure, hydrophobins collect at interfaces between polar and apolar liquids, for example water and oil. Schizophyllan is a nanofiber: less than a nanometer thick, but more than a thousand times as long. Together, these two biomolecules give the living mycelium material properties that make it suitable for a wide range of applications.

A living emulsifier

The researchers demonstrated the versatility of their material in the laboratory. In their study, which was published recently in the journal Advanced Materials, they showcased two possible applications for the living material: a plastic-like film and an emulsion. Emulsions are mixtures of two or more liquids that normally do not mix. All you have to do to see an example is open the fridge: Milk, salad dressing or mayonnaise are all emulsions. And various cosmetics, paints and varnishes also take the form of emulsions.

One challenge is to stabilize such mixtures so that they do not separate into the individual liquids over time. This is where the living mycelium shows its strengths: Both the schizophyllan fibers and the hydrophobins act as emulsifiers. And the fungus keeps releasing more of these molecules. “This is probably the only type of emulsion that becomes more stable over time,” says Sinha. Both the fungal filaments themselves and their extracellular molecules are completely non-toxic, biologically compatible and edible – the split-gill mushroom is routinely eaten in many parts of the world. “Its use as an emulsifier in the cosmetics and food industry is therefore particularly interesting,” says Nyström.

From compost bags to batteries

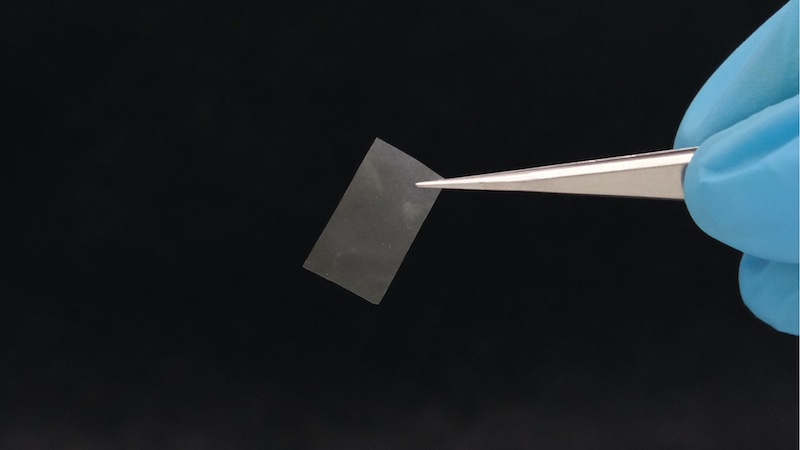

The living fungal network is also suitable for classic material applications. In a second experiment, the researchers manufactured the mycelium into thin films. The extracellular matrix with its long schizophyllan fibers gives the material very good tensile strength, which can be further enhanced by targeted alignment of the fungal and polysaccharide fibers within it.

“We combine the proven methods for processing fiber-based materials with the emerging field of living materials,” explains Nyström. Sinha adds: “Our mycelium is a living fiber composite, so to speak.” The researchers can control the fungal material's properties by changing the conditions under which the fungus grows. It would also be conceivable to use other fungal strains or species that produce other functional macromolecules.

Working with the living material also presents certain challenges. “Biodegradable materials always react to their environment,” says Nyström. “We want to find applications where this interaction is not a hindrance but maybe even an advantage.” However, its biodegradability is only part of the story for the mycelium. It is also a biodegrader: The split-gill mushrooms can actively decompose wood and other plant materials. Sinha sees another potential application here: “Instead of compostable plastic bags, it could be used to make bags that compost the organic waste themselves,” says the researcher.

There are also promising applications for the mycelium in the field of sustainable electronics. For example, the fungal material shows a reversible reaction to moisture and could be used to produce biodegradable moisture sensors. Another application that Nyström's team is currently working on combines the living material with two other research projects from the Cellulose and Wood Materials laboratory: the fungal biobattery and the paper battery. “We want to produce a compact, biodegradable battery whose electrodes consist of a living 'fungal paper',” says Sinha.