#Industry 4.0 / Digitalization

Toray and Soramitsu to trial jointly developed blockchain-based traceability system

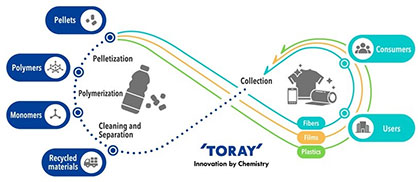

One key goal of the Toray Group Sustainability Vision is to help the world manage resources sustainably by 2050. The company seeks to integrate proprietary recycling, biomass and other sustainable technologies that can contribute to a closed-loop economy. It also looks to integrate its product supply chain with Soramitsu’s blockchain technologies to enhance traceability in product collection, reuse, and other processes. Such an approach would help engage all supply chain stakeholders in achieving a closed-loop economy.

In 2019, Toray launched “&+™”, a sustainable brand that supports efforts to use recycled plastic bottles made of polyethylene terephthalate as raw fiber materials and make such resources traceable. The trial will focus on this brand, with Toray collaborating with companies in its supply chain in organizing to build a basic system that allows anyone, anywhere to verify traceability.

Toray will encourage consumers to actively engage in the recycling process by providing visualization and verification of the closed loop cycle, where consumers can trace the full process from material collection to the production of the end product.

It will also verify frameworks that make it easier for its business partners to integrate information from this system into their own traceability systems.

The company will validate how much energy is used during the recycling process and present information that shows consumers the environmental impact of each product.

Toray will draw on trial findings to sort out issues and substantiate prospects for broadening applications for the traceability system. The company aims to deploy this setup for all the core polymers, including fibers, resins, and films.

Toray will establish a blockchain-based supply chain to deliver total traceability from manufacturing through final product distribution, collection and reusage.

Toray will empower consumers and other stakeholders to participate in a closed-loop economy by enabling them to confirm that the resources sustainably, thus helping to realize a society that readily embraces resource sustainability and closed loop cycles.