#ITMA 2023

Pleva will present advanced technology for energy-efficiency and sophisticated processes at ITMA 2023

Unlocking the gateway to tomorrow’s production

"We enable textile producers to save large amounts of energy, improve product quality and make even complex processes more traceable and reproducible by using high-end sensors and controls with latest technology. In other words, we are unlocking the gateway to tomorrow's production.”

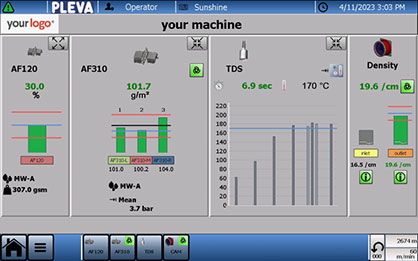

Make sophisticated processes transparent and efficient with PLEVATEC pro: The new, advanced process control system PLEVATEC pro allows an integration of a huge variety of process critical data with all information at one glance and optimal controls. It is designed to enhance and simplify operation even at complex production lines with different modules.

Hereby, tolerances can be set as well as parameters saved and loaded within the integrated recipe management system. The customizable system provides solutions to a huge range of processes, e.g. a production line with foulard, coating and stenter frame.

In general, an integration of the following PLEVA devices is possible:

- Exhaust humidity FSX for great energy savings

- Fabric/air temperature TDS for transparent drying/heat-treatment processes

- Residual moisture RR, RF/AF for improved fabric quality and efficiency

- Application moisture/coating AF/MP for savings of valuable chemicals

- Pick/course density CAM for high quality fabric

Through the continuous process monitoring and control of the parameters, a significant optimization of even very complex production processes is possible. And by having more stable processes, a constant, high quality of the goods is ensured. This means that there are no expensive adjustments or second-choice goods, which saves valuable resources.

The smart way of weft-straightening SL smart: The SL smart is designed for knitted and woven fabrics with a plurality of solutions customizable to fit the individual customer needs. It includes options like fully-integrated accessories for tension- sensitive fabrics, Industry 4.0 applications and more. The heart of the SL smart is the well-established traversing camera technology which is unique in weft-straightening.

The high-resolution camera captures more than 20 measuring points per meter of fabric width. This gives a complete overview of the fabric instead of few fixed positions. Finally, advanced evaluation algorithms ensure an ultra-precise distortion analysis

which enable perfect straightening results in a blink of time. With the weft-straightener SL smart only one round through the production line with the respective fabric is needed and the aimed result is directly produced. This, of course, also saves energy and enhances the production efficiency directly from the beginning.

The all seeing eye – CAM series 400: For the assessment of quality parameters but also weft-straightening, precise detection and advanced image processing is the most important aspect. The brand new CAM offers cutting-edge technology with many novelties for best results: Completely new lighting with increased brightness and special lighting possibilities allow a detection of all kinds of fabric independent from density or color.

This in combination with a four times higher calculation power, higher resolution with five-times more pixels and revised algorithms for calculation of distortion and pick/course density makes it the leading technology in the area. On top, it is also designed as a retrofit for existing PLEVA systems with easy connectors and is fitted for even the harshest conditions thanks to an improved housing design.

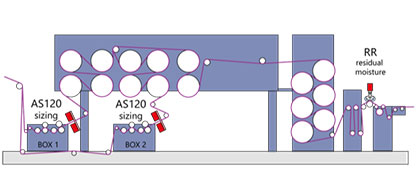

Sizing made sustainable and efficient with updated AS 120: Sizing is the crucial preparation for weaving and high yarn quality. Therefore, sizing agents are applied with a squeezing unit to the warps. To be on the safe side often 10-25% more sizing is applied than required. This implies disadvantages like higher use of expensive sizing agents, more wastewater, unstable yarn quality, lower weaving efficiency, etc. To eliminate those disadvantages, a measurement and control is needed.

The AS 120 measures the size add-on after size box constantly. It includes a newly designed special construction with integrated protection against steam vapours and high temperatures as well as a faster, even more precise electronic. This enables a reliable, continuous monitoring and control. As a result, 1.5% up to 4% higher weaving efficiency is easily possible and at the same time production gets greener.

Besides those new developments, PLEVA also offers special versions of sensors for special demands such as the TDS sensor for fabric and air temperature fitted for EX-zones, state of the art interfaces like Profinet and the PLEVA Remote Service for even faster support of your production. Whether for standard applications

or demanding processes, PLEVA is your partner for the sustainable and efficient production of tomorrow.

PLEVA is looking forward to show all highlights live in hall 11 booth A101!

For more information visit:

https://www.pleva.org

https://www.linkedin.com/company/pleva-sensors-and-controls/