#Sustainability

Forward-looking biomass balance approach raises the renewables share in construction products

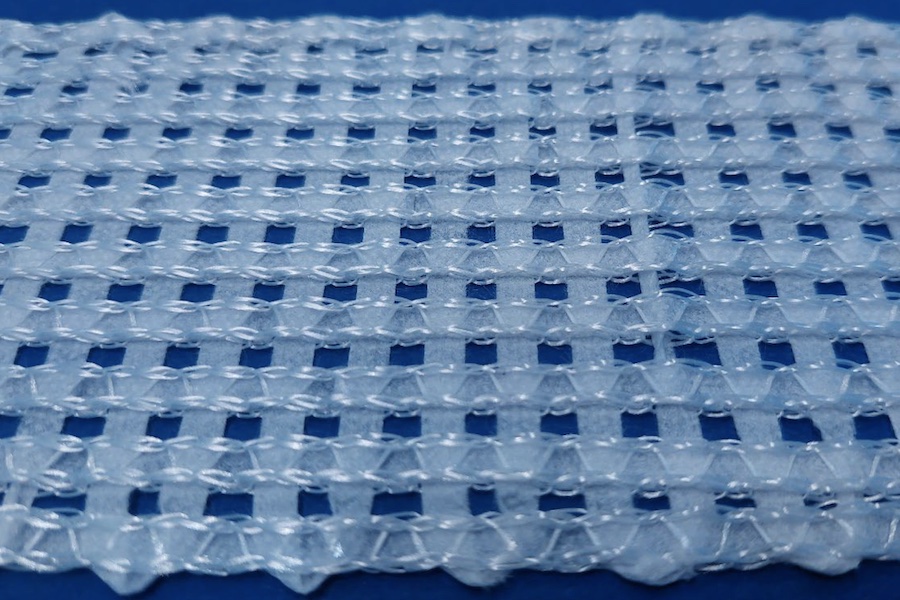

- BASF customer Falk presents innovative sandwich panels produced with BASF’s new biomass balance approach

- Cooperation to cut fossil resources in the construction sector

How it works: The biomass balance in practice

The principle is comparable to that of green electricity. The basic idea involves using renewable resources, such as biogas or bio-naphtha, together with fossil resources in production. The bio share is then arithmetically assigned to certain products using a method certified by the TÜV SÜD technical control board. The share can range from 25 to 100 percent, depending on customer wishes. And with product characteristics absolutely identical to those of the fossil equivalent. “There are no differences in quality or properties. The chemical components derived from renewable and fossil resources are indistinguishable. This means that the construction elements containing our Elastopir® systems always meet the same superlative standards,” says Roel Gunnink, Segment Manager Commercial, BASF Performance Materials.

Joint show of strength

Sustainable action is growing increasingly into a competitive factor that can tip the balance when the customer takes his or her purchase decision. “Each purchase of biomass-balanced products drives the substitution of the relevant quantities of fossil resources with their renewable equivalents at BASF,” explains Jesper Bjerregaard, Head of Marketing at BASF Performance Materials. Ecological responsibility, the conservation of fossil resources, and cutting greenhouse gas emissions go hand in glove with commercial success. BASF helps its customers to adopt innovative methods and exploit new business openings.

Falk is an exhibitor at the International BouwBeurs show in Utrecht, Netherlands, Hall 11, Stand F080, from February 6-10, 2017