#Yarn & Fiber

Toray receives reverse osmosis membrane order for Rabigh 3 desalination plant

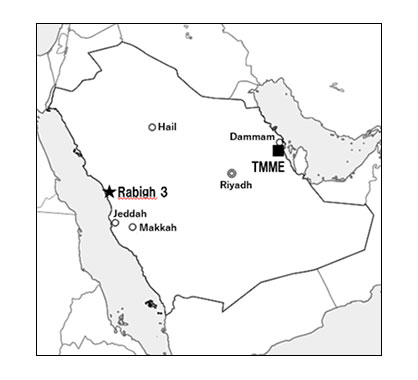

Toray Membrane Middle East LLC (TMME), Toray’s local subsidiary located in Dammam, Kingdom of Saudi Arabia will supply the RO membranes and provide technical services. In keeping with its company principle of reinforcing local services, TMME will supply locally manufactured product, provide commissioning support and autopsy service to help resolve water shortages in the Middle East, which will also ultimately contribute to stable energy supplies to the world.

1. Background

Gulf countries are investing extensively in infrastructure to cater to rising populations. They are pushing ahead with plans to build desalination plants to secure sufficient drinking water. With increasing awareness of environmental footprints and cost reduction, construction of RO Desalination Plants which consume less energy than conventional evaporation method is increasing.

The award of RO membrane supply order for Rabigh 3 Desalination Plant was realized from Toray’s solid desalination reference over a decade, operation record, and efficient proposal based on past experience in the region.

2. Looking ahead

Over the years, Toray has expanded its RO membrane sales, production, and technical support to help resolve water issues around the globe. Applications extend from desalination, wastewater reclamation and industrial usage, achieving the total accumulated water production capacity of over 91,400,000m3/day, which is equivalent to serve the water needs of 640 million people, or around 8% of the world’s population.

Ensuring supplies of safe and clean water is Toray’s top theme announced both in “Toray Group Sustainability Vision” on July 2018 and in “Toray Vision 2030” on May 2020. Toray will continue supplying RO membranes and other advanced membrane products while strengthening technical services to meet local demand, striving to help overcome the challenges of ever growing water demand in the Middle East.

Order details

Rabigh 3 Desalination Plant

Location: Rabigh, Kingdom of Saudi Arabia

Production capacity: 600,000 m3/day

Expected Operation Start: Q4 2021

Developer: ACWA POWER (70%) / Saudi Brothers Commercial Company (30%)

EPC Contractor: Abengoa Agua S.A. / TIEJUN / SIDEM

Background of establishment of TMME

Toray established TMME in Dammam 3rd Industrial City in 2015, in harmony to Saudi Vision 2030. This vision was launched by the Kingdom of Saudi Arabia to reduce its dependence on oil and achieve diversified economy. TMME has earned an outstanding reputation on its product and technical service through the numerous references achieved with the Made in KSA reverse osmosis membranes, and shall further contribute to the Saudi Vision 2030.

Toray Water Treatment website

https://www.water.toray/