#Research & Development

Sustainable design of Geosynthetics and roof underlayments made from recyclates

The Fraunhofer institutes attach particular importance to the practical relevance of their new developments. This example shows the use of geosynthetics in riverbank stabilization. © Fraunhofer LBF/Raapke

As an alternative to mechanical processes, they are jointly developing innovative recycling methods for the production of sustainable roof underlayments and geosynthetics. This involves the analysis of the entire value chain at pilot scale.

The market for recycled plastics, especially polypropylene (PP) and polyethylene terephthalate (PET) recyclates, still holds significant potential. Demand for sustainable solutions is growing, but the quality of the available recyclates needs to improve. Many recycling processes fail due to contaminants that complicate processing, so recyclates are often still unable to compete with virgin materials. Together with the Fraunhofer Institute for Molecular Biology and Applied Ecology IME and the Fraunhofer Institute of Optronics, System Technologies and Image Exploitation IOSB, the six institutes of the Fraunhofer CCPE Cluster aim to overcome this limitation and bring about change. In the project Zirk-Tex (from the German for “circular textile sheet structures”), they are investigating whether it is possible to produce recycled plastics from previously unused plastic waste streams for high-quality films, nonwovens and fibers that can be further processed into roof underlayments. Several hundred million square meters of roofing underlay membranes are installed in Europe every year.

At the same time, biopolymers are still often viewed as lacking the properties required for demanding technical applications. In the project’s second use case, the partners succeeded in producing contaminant-free fibers from biopolymers, specifically polylactide (PLA) and polybutylene succinate (PBS), for the manufacture of biodegradable geotextiles whose degradation in the environment can be controlled. Biodegradable textiles of this type are used for the temporary stabilization of slopes and riverbanks, for instance, or for the construction of temporary access roads on building sites.

Cost-effective production of roof underlayments from PP and PET

“Producing injection-molded components from plastic recyclates is comparatively straightforward. It is much more challenging to use them to manufacture textile products such as nonwovens for roof underlayments, however, because filament-forming processes place extremely high demands on the recyclates. The feedstock material has to be homogeneous and entirely free of contaminants in order to be extruded uniformly through extremely fine capillaries and, after extrusion, to withstand what are in some cases very high tensile forces,” explains Evgueni Tarkhanov, researcher at Fraunhofer IAP. “Processing stability is absolutely crucial for the production.” Even small amounts of impurities or foreign polymer represent defects in the extruded filament, which increases the probability of breaks in the production process. Replacing filament bundles onto the yarn guides is time-consuming and can result in production lines being shut down in some cases, incurring considerable costs.

Rethinking the entire value chain

“In order to be able to manufacture roof underlayments from post-consumer waste, we cover the entire process chain for PP and PET at pilot scale, from the analysis of sorting processes (Fraunhofer IOSB) and innovative recycling methods (Fraunhofer ICT and Fraunhofer IVV) through to the application stage. A granulate or compound is produced by recycling suitable waste plastics. This is then additivated (Fraunhofer LBF) and further processed by melt spinning into nonwovens, films or membranes,” says Christian Schütz, researcher at Fraunhofer LBF and head of the project. The research team’s work involved assessing the potential of two recycling processes: The PET fraction underwent glycolysis, a chemical recycling process followed by repolymerization, while both PP and PET fractions were recovered using a solvent-based recycling process that includes purification. Residues from both recycling processes were further utilized by means of pyrolysis (Fraunhofer UMSICHT). The practical work was supported by a life cycle assessment (Fraunhofer UMSICHT) and a material flow analysis of available material streams (Fraunhofer IML).

Innovative recycling processes for uncontaminated recyclates

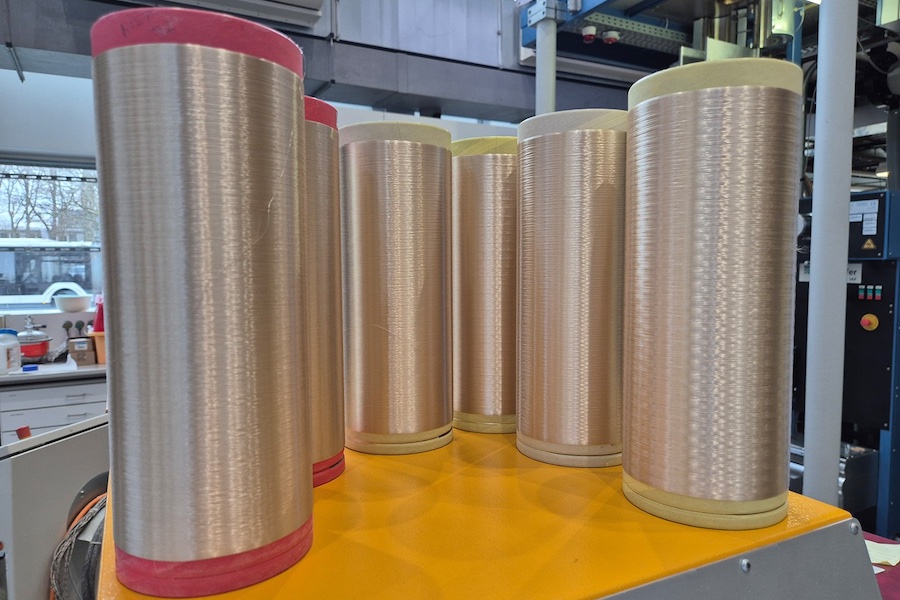

Using the solvent-based recycling process developed by Fraunhofer IVV, the research team was able to separate PP from unwanted polymers and additives, resulting in an almost uncontaminated material. The waste stream initially contained 33 percent PP and 67 percent foreign plastics. After processing, polyethylene (PE) was the only significant remaining unwanted polymer, with a share of less than 2 percent. The team also ensured the stability of the PP recyclate at high processing temperatures. The recovered rPP was then spun into a multifilament yarn at Fraunhofer IAP. “Thanks to the right additivation strategy, we were also able to significantly improve the processing stability of both PP and PET recyclates,” says Schütz.

For the PET glycolysis carried out at Fraunhofer ICT, the researchers used PET trays containing 13 percent unwanted impurities. Glycolysis is a form of solvolysis in which ethylene glycol is used to depolymerize PET into bis(2-hydroxyethyl) terephthalate (BHET). “Solvolysis involves plastics being selectively broken down into their respective monomers using a depolymerization reagent,” explains Schütz. The resulting BHET was repolymerized into rPET at Fraunhofer IAP and processed on a pilot melt-spinning line into a multifilament yarn with 48 filaments. In addition, the researchers demonstrated that the same PET fraction can also be recycled using a solvent-based recycling process. “We were able to obtain fibers from both PP and PET for the production of nonwovens, and, in the case of PP, also for membrane production,” says Tarkhanov.

Pyrolysis of residues from the solvent-based recycling process of the PP fractions yielded a high proportion of pyrolysis gas and a low proportion of coke, while pyrolysis of residues from PET solvolysis yielded pyrolysis oil fractions with a high oil proportion and low coke contents. The products from both feedstock streams show good potential for further utilization.

The accompanying analyses also revealed that suitable and sufficient quantities of PP and PET are available, but that the logistics and sorting infrastructure required to access these still need to be established. The aggregated life cycle assessment results showed that the value chain of the process developed by Fraunhofer CCPE offers a better climate footprint for both biopolymers and recyclates than the use of virgin plastics. “We were able to successfully demonstrate that previously unused material streams are a viable option for the production of high-quality recyclate-based materials,” says Schütz.

Biodegradable geotextiles made from PLA and PBS

Can plastics be manufactured for landscaping applications from biobased polymers (PLA and PBS)? Is it possible to make products that degrade in a controlled manner and do not cause environmental problems? How do we ensure that PLA and PBS remain stable during use and then degrade quickly and completely afterwards? These questions are addressed by Fraunhofer CCPE in the second use case of the project, which focuses on geotextiles designed for short-term applications of less than 10 years and therefore require rapid degradation. The focus here was on the biodegradability and ecotoxicity of the bioplastics, with tests conducted using virgin PLA and PBS materials. In order to assess biodegradability, the project partners stored fibers of two PBS types and three PLA types for 25 weeks at Fraunhofer UMSICHT at 40°C and 90 percent relative humidity in moist soil. Using tailored additives developed by Fraunhofer LBF, the researchers succeeded in controlling the onset and progression of degradation of the PLA and PBS fibers and significantly accelerating it, as demonstrated in degradation tests, while largely maintaining the material properties until the start of degradation. “For both PLA and PBS, we were able to produce fibers with controlled and adjustable degradation behavior,” says Schütz. “Ecotoxicity tests conducted by Fraunhofer IME showed no indications of adverse effects. Our results provide a concrete development perspective for the use of geotextiles in real-world applications, and we now intend to pursue these further in collaboration with industry partners.”