#Home Textiles

Trevira at the 2020 Heimtextil trade fair

A thriving partnership – value-creating innovations – future-oriented applications

Joint booth with Trevira CS customers and partners

Trevira’s customers will present their Trevira CS collections for the home textile sector and the contract market at individual stands, thus demonstrating their contribution to the textile value chain.

The following customers and partners will join Trevira at the joint booth to present their wide range of attractive, modern Trevira CS yarns and fabrics:

Ambience Home Textiles, Chamatex, Dina Vanelli, Engelbert E. Stieger, FIDIVI Tessitura Vergnano, Gebrüder Colsman, Gebrüder Wylach, Georg + Otto Friedrich, Hoftex, llcat by Leitsu, JAB Josef Anstoetz, Jenny Fabrics, Lodetex, Lonfil, Mattes & Ammann, Mewes, Mottura, Panaz, Pozzi Arturo, Pugi, Spinnerei Lampertsmühle, Spandauer Velours, SR Webatex / Getzner Textil, Tessitura Mario Ghioldi, Tintoria Sala / F.lli Baroni, Torcitura Fibre Sintetiche, VLNAP / Wagenfelder Spinning Group, and Wintex.

“Once again, we rely on our trade fair concept of a joint booth together with Trevira CS customers and partners and once again, we have increased the number of our co-exhibitors. This shows that our concept is successful. This also means that we are able to provide visitors to our booth with an even more extensive overview of Trevira CS products and applications,” says Trevira CEO Klaus Holz.

Trevira’s joint booth, which will be situated in Hall 4.2, immediately next to the Messe Frankfurt exhibition “Interior. Architecture. Hospitality. EXPO”, will also feature a special showcase, “Textile Future by Trevira CS” especially for the contract market. To curate this special display, Trevira is proud to have secured a collaborative partnership with renowned Berlin design company studio aisslinger. The studio is known for its outstanding work in experimental and product design, innovative materials and architectural concepts. As a designer, studio founder Werner Aisslinger is particularly interested in how the latest technologies and unusual materials can be used in product design. In addition to designing furniture, his most recent projects mainly include interior design concepts for hotels and workspaces.

The special exhibition, “Textile Future by Trevira CS”, will give visitors, especially architects, interior designers, and decorators, an opportunity to find out more about future-oriented, innovative applications of Trevira CS fabrics on the contract market.

“With our Heimtextil 2020 trade fair booth, we again look forward to offering a networking platform that will be of special interest to decision-makers on the contract market. Our aim is to provide not only an extensive overview of Trevira CS products and collections but also to inspire visitors to rethink textile applications for future projects in the areas of public spaces, workspace, hospitality, health and care, as well as mobility. Our special exhibition will enable visitors to do just that, away from actual projects,” says Anke Vollenbröker, Head of Marketing at Trevira GmbH.

Trevira Innovation Park

At the 2020 Heimtextil trade fair, Trevira presents its new concepts and innovations directly at the entrance to its trade fair booth in the „Innovation Park“.

Trevira CS – A new brand concept for more flexibility and sustainability

Trevira CS collections are becoming more and more ambitious in their designs – and this at a time when the market is increasing its demands and fresh end uses are being developed. In appearance it is frequently impossible to distinguish them from textiles made from natural fibres. At the same time there are fresh surfaces appearing, seemingly technical, which can only be achieved with the use of man-made fibres. This is made possible by continual expansion of the fibre and yarn programme, which increasingly contains new fancy and textured yarns from spinners and yarn finishers. It is thanks to their creativity that fabric designers can draw on the most varied and innovative range of flame retardant yarns when they create Trevira CS materials. Flame retardant Trevira fibres and yarns are thus not only the basis for the functionality of textiles, they also ensure that manufacturers and fabric houses are able to set international trends.

To meet the ever more complex demands of the market and offer our customers and partners greater flexibility, the Trevira CS concept has been expanded to include two new brands, Trevira CS flex and Trevira CS eco. Besides the high brand quality and performance that Trevira CS customers have come to expect, these two new brands offer properties and functionalities especially tailored to meet specific requirements.

Recycling at Trevira – sustainable in many ways

Trevira pursues various approaches to meet the demand for and different requirements on sustainable products. All recycled Trevira products are being certified in accordance with the GRS standard (Global Recycled Standard).

Trevira CS: pre-consumer recycling

When polyester fibres and filaments are manufactured, the process inevitably results in some residual waste. However, this residual waste is actually a precious resource that can be recycled for further use. To ensure resource-efficient use of materials, Trevira is committed to feed our residual waste back into the production process wherever possible. Our agglomeration facility is able to reprocess residual materials in order to create new serviceable raw materials. These processed recyclates retain the same characteristics as the original products (such as flame retardancy) and are thus equally high performing. They can be deployed in our fibre and filament spinning mills to make new, high-quality products. Fibres thus created can be processed into yarns that consist of 100% recycled fibres.

The Mario Ghioldi Company has used this type of yarns to manufacture fabrics that consist of 100% flame-retardant, recycled materials (pre-consumer). In future, the Trevira CS eco brand will be available for this type of textile fabrics.

Trevira CS: post-consumer recycling

The recycling of PET bottles is an important contribution to environmental sustainability. Flame retardant recycled Trevira filament yarns are made from recycled PET bottles and consist of 50% recycled materials (post-consumer).

Standard Polyester: spun-dyed recycled

Trevira uses regranulates made from PET bottle flakes to create both filament yarns as well as fibres. These filament yarns, made from recycled PET bottles, are available in raw white and spundyed flat and textured yarns in standard polyester and in various colours and titers. Alongside technical applications, they are used in the automotive and apparel sectors. Their recycled content is 100%.

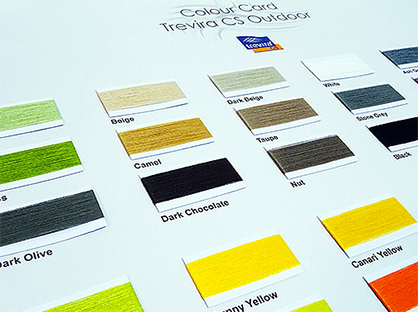

Trevira CS Outdoor – high performance in colour

Another current topic is the use of Trevira CS fabrics in outdoor products since people continue to enjoy the outdoors. Consequently, outdoor spaces in both the private and public sectors are being extensively decorated with high-quality products. When it comes to textile materials, there is a high demand for fabrics with an especially nice feel and a wide range of colours; after all, people do not want to give up comfort and design when outdoors. Especially in the hotel, restaurant, and shipping industries, which require fabrics for both indoors and outdoors, there are very high demands on textiles. Materials for indoor use must comply with fire safety regulations, whereas materials for outdoor use require high performance with regard to resistance to light and tearing. In order to produce high-performing and well-designed textiles, Trevira now offers six more colours in addition to the existing range of 24 UV-stable, spun-dyed filament yarns (Green, Dark Beige, Taupe, Canary Yellow, Charcoal, Light Beige). Spun-dyed yarns, i.e. yarns dyed by adding colour with the master batch to the spinning mass, have a high degree of light resistance. A UVstabiliser is also added to the spinning mass, which increases the resistance of the yarns and the fabrics made from them. In addition to a depth of colour and resistance, spun-dyed yarns have another advantage: They are more sustainable than yarn-dyed products because of the omission of additional steps in the dyeing process that are harmful to the environment. This process also saves money and energy. Trevira has won the “Brandenburg Innovation Award for Plastics and Chemistry 2019” for this product development.

Also fancy yarns, like for example chenille yarns of the Lonfil company are available in flame retardant, spun-dyed, UV-stable versions.

At Trevira’s trade fair booth, for the first time a knit velour is presented, that is suitable for outdoor use. It is manufactured by Mattes & Ammann and consists of 100% flame retardant, spun-dyed, UV-stable Trevira filament yarns. Three colours were used to produce the fabrics.

Furthermore, visitors will be able to see cushions made by PIF Textile, with cover fabrics consisting of spun-dyed, UV-stable, flame retardant Trevira yarns.

Trevira CS Dim Out – function and design for day and night

Flame retardant dim-out or coated black-out fabrics are used in numerous hotel projects to darken rooms. These products are mainly selected for reasons of functionality and cost, while quality and design play a subordinate role. Those in search of a more high-quality textile alternative of darkening curtains that also has an attractive feel to it, can soon avail of a wider range of flame retardant Trevira CS fabrics. Spun-dyed Trevira CS filament yarns are the basis for these high-end qualities and they are available in various dimming levels depending on the fabric construction.

Trevira CS CAT – for a leading edge in design

Melange designs continue to be an important trend for home textiles, in particular with strong and contrasting properties of matching shades. The use of yarns that are cationic dyeable is one way to achieve this effect. When these yarns are combined with conventionally dyeable yarns, they can be immersed in a one-step dye bath with two different dyes (cationic and discationic). The yarns absorb different amounts of colour, thus creating a melange effect. Trevira offers both flame retardant, cationic dyeable fibres and filament yarns. The Trevira Innovation Park will display a Trevira CS melange fabric, manufactured from fibre yarns, made by Tintoria Sala. The yarns consist of a combination of normal and cationic dyeable fibres. Dyeing these different types of fibres together results in bicoloured yarns that can be used to achieve a melange effect. The cationic proportion of the yarn can be adjusted to meet individual customer demands.

A strong combination – high-tenacity, flame retardant yarns

In addition to the already well-known flame retardant yarns for the home textile sector, Trevira now also offers flame retardant high-tenacity polyester yarns that can be used in various areas such as industrial applications or protective clothing. Produced from flame retardant Trevira raw material, PHP Fibres (Trevira’s sister company in the IVL Group) markets high tenacity drawn flat yarns. Trevira refines these flat yarns into flame retardant air-textured yarns also having high tenacity properties, thus offering another interesting yarn alternative.

Trevira CS antimony-free – quality for special requirements

Today, Trevira’s flame retardant fibres are antimony-free as a standard. The aim is to continue to improve product safety and to satisfy potential client requirements for antimony-free products for specific applications. The entire Trevira range of fibres is now available for customers that require antimony-free products. Trevira is also planning an antimony-free version of filament yarns.