#Yarn & Fiber

Trevira CS makes its debut at Clerkenwell Design Week in London

The London borough of Clerkenwell is home to more creative businesses and architects per square mile than anywhere else in the world, making it one of the most important design hubs in the world. To celebrate this rich and diverse community, Clerkenwell Design Week has created a unique opportunity to showcase the world's leading interior design brands. With more than 600 events in over 160 showrooms, more than 11 curated exhibitions, stunning installations, talks and a supporting program, CDW has established itself as the UK's leading design festival. The Trevira CS stand is part of the "German Collection - home to German Contemporary Design", which brings together a leading selection of renowned German brands. It can be found at 1 Sekforde St., London EC1R 0BE.

Unlimited possibilities

In addition to their inherently flame retardant properties, Trevira CS fabrics are characterized by their variety of designs and areas of application. The Trevira CS portfolio available on the market offers a veritable treasure trove of high-quality fabrics that can be used to create sophisticated interiors - in hotels and restaurants, in the care sector, in working environments, in means of transportation or in public buildings. Here, but also in private homes, the fabrics also impress with their easy care properties.

On duty outdoors

On duty outdoors: Flame retardant, spun-dyed, UV-stable Trevira® filament yarns

The product range of flame-retardant Trevira® filament yarns now also includes 30 spun-dyed, UV-stable yarns, which are particularly suitable for outdoor use in fabrics in the hospitality sector and on cruise ships due to their high light fastness and UV resistance. They also score points for their sustainable properties, as the fabrics made from them can be produced in a more environmentally friendly way than textiles made from conventional yarns. The use of spun-dyed yarns is easy on the environment, as dyeing processes for yarns and fabrics are no longer necessary, meaning that fewer resources such as energy, water and chemicals are required. The durability of the textiles is also given under outdoor conditions: permanent color strength, no fading, UV stabilization for long-lasting durability.

The Trevira CS sustainability concept: sustainable in many ways

The Trevira CS brand pursues various approaches in order to achieve the best possible sustainability balance over the life cycle of the product, from the fiber/filament through to recycling options for textiles that can no longer be used. Various recycling methods are used, from mechanical to chemical recycling.

Recycling solutions

Trevira CS fabrics are also available in recycled versions. They consist of fiber and filament yarns that are obtained in various recycling processes. Fabrics made from these yarns can obtain the Trevira CS eco trademark. The prerequisite for this is a recycled content of at least 50%.

The Trevira CS eco textiles available on the market today go far beyond the initial basic articles in terms of design, look and feel. Almost all fabric qualities are available: light, transparent curtain fabrics, flowing, shiny decorative fabrics, materials in natural looks, flat woven fabrics and velvets for use as upholstery fabrics. Articles for interior sun protection are also available in Trevira CS eco quality.

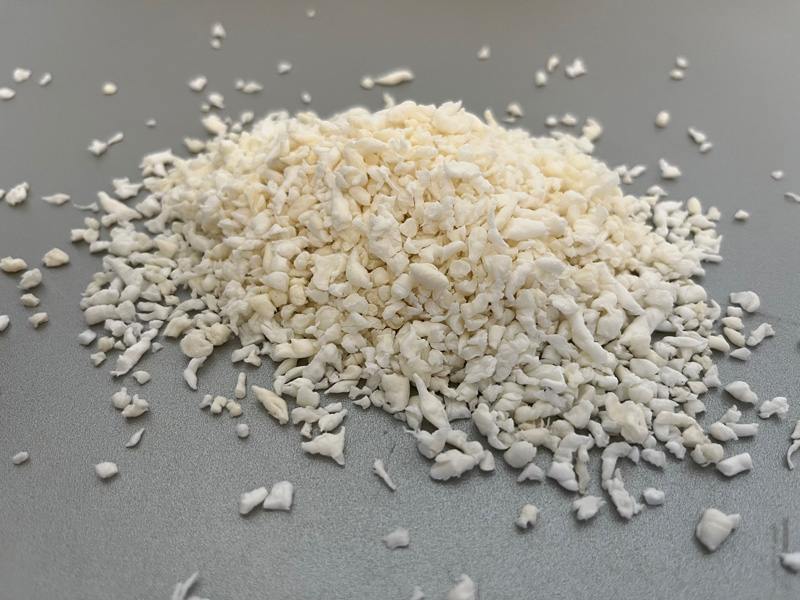

Mechanical recycling: Use of bottle flakes and agglomerate

Flame retardant Trevira® filament yarns are produced using recycled PET bottles and contain 50% post-consumer recycled material. Recycled fibers are obtained using an agglomeration plant and in further process steps from recyclable materials from production and consist of 100% recycled material (post-industrial recycling). These flame-retardant, recycled Trevira products are GRS (Global Recycled Standard) certified.

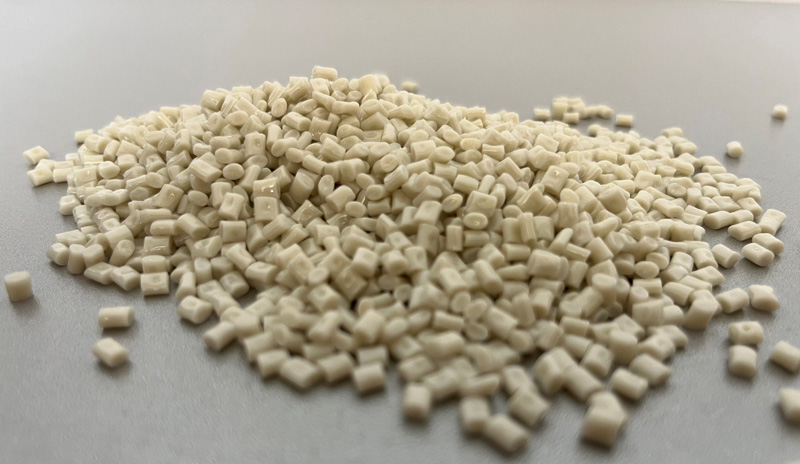

Advanced / chemical recycling: The next generation of flame retardant fabrics

The long-term goal in the development of sustainable products is to enter a closed-loop economy. Chemical recycling opens possibilities for approaching this goal.

Indorama Ventures has launched an innovative Trevira CS product development in which flame-retardant fibers and filament yarns are made from chemically recycled raw material. The products are made from 100% recycled material. Currently, PET material from the packaging industry is used here, which is not suitable to be re-used in the manufacture of bottles/packaging material.

Chemical recycling involves depolymerization, a sequence of chemical reactions in which the polymer chains are broken down again into their original components, i.e. the monomers. The raw material obtained from the recycling process is comparable to the original material and can be used again in high-quality products.

The greatest advantage, however, lies in the potential that this approach unlocks for the future. Today, the chemically recycled raw material used to produce flame-retardant Trevira® fibers and filament yarns is obtained from PET waste from the packaging industry, but in principle it could come from almost any other recycled PET material, even from textiles.

With these first steps, the path to a circular economy is underway - waste can be avoided and resources conserved. In future, it may be possible to use chemical recycling to obtain raw materials for new textiles from textile waste.

Back to a new life: The Trevira CS take-back program

Used Trevira CS fabrics can be returned and recycled as part of the Trevira CS take-back program. This applies to textiles from the pre-consumer sector such as unsold remnants, discontinued items, offcuts, defective goods, etc. as well as textiles that have reached the end of their useful life (post-consumer).

The Trevira CS fabrics are collected at the recycling company ALTEX Textil-Recycling GmbH & Co. KG and undergo a mechanical recycling process. The final products are nonwovens, which are used in various sectors for example for insulation and soundproofing. Of particular interest is their use as acoustic systems, for example in the form of sound-absorbing wall coverings, free-standing partitions, ceiling suspensions or decorative objects.

The take-back system offered is a program for Trevira CS fabrics only (i.e. Trevira CS, Trevira CS flex, Trevira CS eco). Proof that the fabric in question was manufactured from flame retardant Trevira® fibers and filaments or the products of the further processing stages (spinners, texturizers, etc.) is provided by presenting the Trevira CS trademark approval. This confirms that the fabric has passed the fire test indicated in the trademark conditions and has been approved for the Trevira CS trademark.

At ALTEX, nonwovens with a basis weight of 600 – 3,000 g/sqm can be produced for a wide variety of applications. One project is the production of a flame-retardant nonwoven for use in an acoustic panel. For this purpose, torn fibers from Trevira CS fabrics are used, which are processed into the corresponding nonwovens if applicable by adding new fibers and/or low-melt fibers. It is important to adapt the function, thickness and strength of the nonwoven to the corresponding area of application. If the resulting nonwoven is covered with Trevira CS or Trevira CS eco fabrics, the result is a new, attractive, functional product that helps to avoid waste and conserve resources.