#Techtextil 2024

Focus on road safety and health protection - Oerlikon presents sustainable technologies at Techtextil 2024

More safety in vehicles with high-performance filament yarns

In modern passenger cars today, an average of 30 to 35 kg of yarn ensures safety and comfort. Airbags play a large part in this: the yarns used are mainly made of polyamide. Due to the ever increasing variety of airbag applications and the ever growing size of the systems, polyester is also often used today, depending on the application requirements and cost/benefit considerations. In addition to high productivity and low energy consumption, the technologies from Oerlikon Barmag score particularly well with their stable production processes. "They meet all the high quality standards for airbags, which – like almost all other textile products in vehicle construction – must guarantee maximum safety for the occupants," confirms Dr. Jen Supra, Technology Manager Technical Yarn at Oerlikon Barmag. "And without any loss of function in any climate, anywhere in the world, for the entire service life of the vehicle."

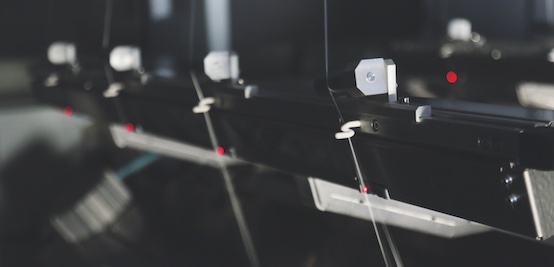

Seat belts also play a life-saving role in vehicles. They must be able to withstand tensile forces of more than three tons and at the same time stretch in a controlled manner in an emergency to reduce the load in the event of a collision. A seat belt consists of around 300 filament yarns, whose individual high-strength yarn threads are spun from around 100 single filaments. Oerlikon Barmag's patented Single Filament Layer technology ensures a High Tenacity (HT) yarn process that is as sophisticated as it is gentle.

Safe on the road – reinforcement with geotextiles

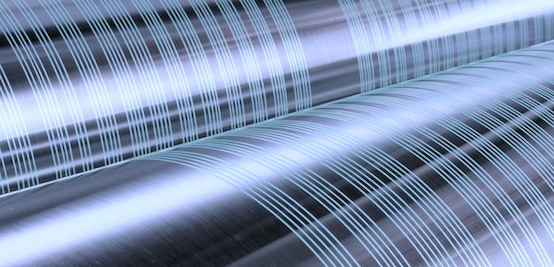

But technical yarns not only have advantages in the car, but also underneath it. Low elongation, ultra-high tenacity, high rigidity – technical yarns offer outstanding properties for the demanding tasks of geotextiles, e.g. as geogrids in the base course system under the asphalt. Geotextiles usually have extremely high yarn counts of up to 24,000 denier. System concepts from Oerlikon Barmag simultaneously produce three filament yarns with 6,000 denier each. Thanks to the high spinning titer, fewer yarns can be plied together to the required geo yarn titer in a more cost and energy efficient way.

The geotextile portfolio is complemented by Oerlikon Nonwoven's spunbond technology: the process for the production of nonwovens for the manufacture of geotextiles made of polyester or polypropylene is characterized by high production capacities and yields with low energy consumption.

Filter efficiency of over 99.99% with hycuTEC

The hycuTEC hydrocharging solution from Oerlikon Nonwoven is a unique technology for charging nonwovens to increase filter efficiency to over 99.99%. For meltblown producers, this means a 30% material saving with significantly increased filtration performance. For the end user, this is noticeable in a gain in comfort due to the significantly reduced breathing resistance. With significantly lower water and energy consumption, the patent-pending technology is recommended as future-proof and sustainable.