#Spinning

Industrial yarn producer sees growth potential in tire cord sector

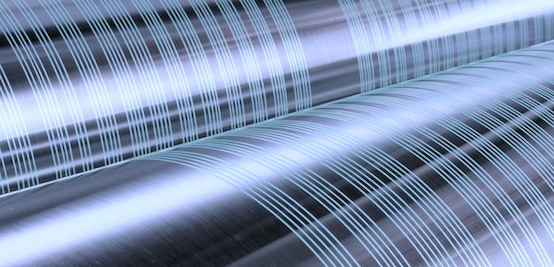

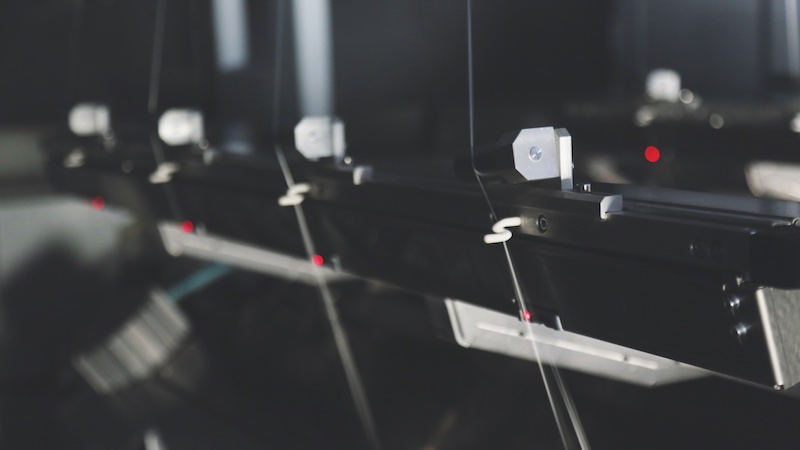

Junma processes the tire yarn produced in the titer range of 1100 dtex to 2200 dtex in-house into tire cord using the downstream processes of dipping and weaving. The largest HMLS single project for Junma and Oerlikon Barmag to date was put into operation in record time. After just two weeks, the various yarn specifications were approved. “The fact that we achieved the required yarn parameters so quickly shows how reliable our industrial yarn systems are,” says process engineer Li Jiangang. “Our systems guarantee a stable spinning process and reliably produce quality yarns – our many years of experience in the industry help us here.”

Wang Hongbin, General Manager at Junma, is also aware of this: “We entered the HMLS polyester tire cord manufacturing business in 2008 and at the time, we decided on Oerlikon Barmag systems. All the subsequent expansion stages have confirmed our decision from back then; today, we are convinced Oerlikon Barmag customers.”

High-end HMLS technology for the international tire market

Junma supplies its end products to renowned international tire manufacturers and sees definite growth potential in this segment of the automotive industry. “This year, we opened our first branches outside of China. And for the coming year, we are planning our first production facility in Thailand,” says Wang Hongbin. In doing so, Junma continues to rely on the expertise of Oerlikon Barmag. The HMLS process from Oerlikon Barmag scores particularly highly with production speeds of up to 6300 m/min, at which the core components of high-speed godets and winders demonstrate their reliability.