#Spinning

The world’s first 12-head comber: TCO 21XL

Real-world results from spinning companies worldwide – including Bakan Tex in Uzbekistan – have confirmed the TCO 21XL’s high levels of performance and quality. Why is this new comber grabbing attention among top spinning companies?

Great performance in Uzbekistan

Trützschler customer Bakan Tex, headquartered in Uzbekistan, has already enjoyed an exclusive sneak-peek at this machine. Bakan produces 14,500 tons of combed cotton yarn per year (ranging from Ne 20 to Ne 40) at its state-of-the-art spinning mill. The company has a high degree of automation and focuses on future-oriented technologies.

“The production and quality data of the TCO 21XL are simply fantastic,” says Mr. Sekar, General Manager at Bakan Tex. “We’re incredibly excited about how the 12-head comber is going to benefit our business.”

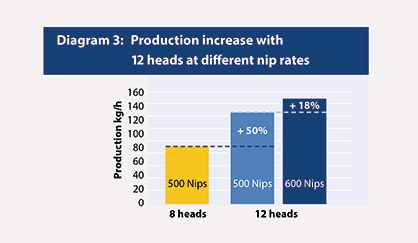

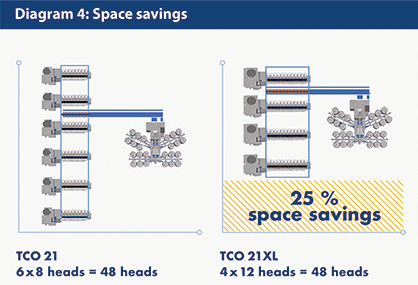

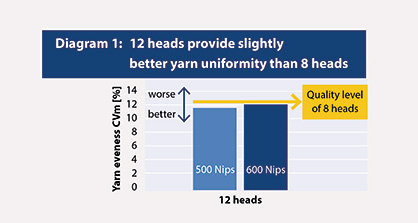

Bakan Tex was able to perform a comprehensive comparison between eight-head and twelve-head machines under identical production conditions because it already has TCO combers installed. You can see the results on Diagram 1 and Diagram 2. These trials were carried out for ring spinning with uzbek cotton as the raw material. The yarn count was Ne 30.

Further results are promising

The team at Bakan Tex was thrilled to see how one comber can meet its market needs so effectively. Further results in Turkey, for example, confirmed higher productivity at no compromise in quality, stable running performance and very satisfactory endurance test results.

Lower cost of ownership

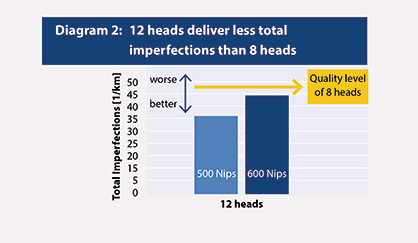

Next to boosting productivity, the TCO 21XL requires 25 % less space to accommodate the same number of combing heads (see Diagram 4). This reduces initial construction costs and also results in lower ongoing operating costs, including costs associated with lighting, air conditioning and other overheads. Trützschler's new ONLINE NOIL MONITORING function also enables further cost savings by automatically detecting variations in the noil and giving a warning signal in case of significant changes. Of course, the TCO 21XL also features the proven drive technologies DUAL DRIVE and 2TWIN DRIVE for a completely synchronous running on all combing heads and a uniform combing result.

Trützschler is excited that this innovative comber has started fulfilling its most important role - delivering outstanding productivity and quality to customers worldwide!