#Spinning

Improving quality with service products

3rd block of webinars with a focus on customer service

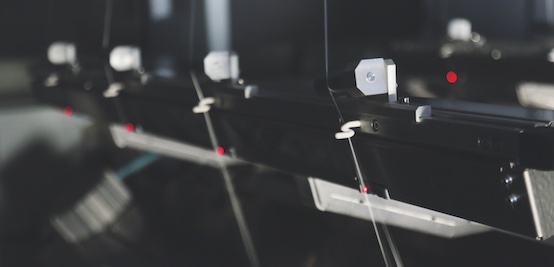

How ceramics within the yarn path improve the quality of your yarn

September 01, 2021: 2 – 2:45 p.m. CET

Catering to the ever-greater requirements in terms of yarn quality and production speeds requires specially-designed yarn guides made from new materials. They help optimize the yarn production process. Here, the yarn guide and yarn oiler become two of the most important components coming into contact with the yarn within spinning and texturing machines. Regional Service Sales Director Ingo Scholz and Technical Project Manager Michael Kochanek illuminate how the right selection of the ceramics used here can guarantee superlative yarn quality with maximum production speeds and outstanding durability.

myOerlikon – tailored digital services provide a comprehensive overview

September 13, 2021: 2 – 2:45 p.m. CET

Ingo Scholz, Regional Head of Service Sales at Oerlikon Barmag, and Oerlikon Neumag’s Regional Service Sales Manager Finn-Eric Jordt introduce the myOerlikon service portal and e-commerce platform. With this solution, Oerlikon customers across the globe have access to all machine and sales documents, drawings and operating instructions via the Web-based portal. The team of speakers from both brands will demonstrate how to quickly and easily order spare parts and how e-learning offerings, videos and machine-accompanying information can be accessed.

Always by your side – with Oerlikon Remote Services

September 22, 2021: 2 – 2:45 p.m. CET

Professional service is relevant in all phases of a system’s life. And it also plays a decisive role above all with regards to unforeseen events and incidents. Within the context of a presentation by Thomas Arnold, Head of Technical Services at Oerlikon Barmag, and Jan Pauer, Technical Service Manager for Modifications at Oerlikon Neumag, attendees will discover how yarn producers can utilize the Manmade Fibers Solutions business unit’s Remote Service to avoid longer downtimes.

Better safe than sorry – maximize productivity and minimize downtimes with regular machine check-ups

September 29, 2021: 2 – 2:45 p.m. CET

Superlative performance is the result of the interaction of numerous factors. Preventative equipment maintenance work is a simple way of avoiding unplanned machine downtimes. Oerlikon Neumag Expert for Industrial Services Christopher Hansen and Michael Schwarz, Technical Sales Manager for Modifications at Oerlikon Nonwoven, explain how services can be improved, future-proof system concepts developed and cost potentials tapped into.