#Spinning

Strong results for Oerlikon Manmade Fibers Division in Q3

- Strong Group performance: >200 basis points improvement in operational EBITDA margin while sales declined 6% year-over-year; showing strength of portfolio and effective cost actions.

- Manmade Fibers on track to achieve over CHF 1 billion of orders and sales in 2020; margin performance ahead of target.

- Surface Solutions orders and sales improved sequentially with further positive trends in September. Automotive recovering faster than expected. Cost measures yielding results: operational EBITDA margin of 14.8%.

- Cost programs ahead of plan and delivering results: >650 of targeted 800+ headcount reduced as of end September 2020; annualized run-rate savings of CHF ~70 million expected.

- Further empowering operating businesses and increasing customer focus by appointing Division CEOs as members of the Executive Committee, effective January 1, 2021.

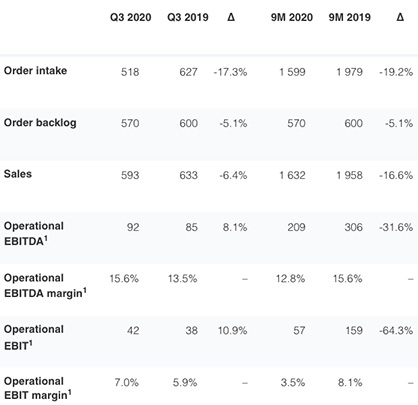

Key figures of the Oerlikon Group as of September 30, 2020 (in CHF million)

“Our Q3 results show the strength of our businesses and the impact of our decisive cost actions,” said Dr. Roland Fischer, CEO Oerlikon Group. “Our manmade fibers business is stable and on track for its targeted deliveries for 2020. In Surface Solutions, we are ahead of our schedule on executing structural cost-out measures and the benefits can already be clearly seen in our third quarter results.”

“In line with our plans to further empower our operational businesses and increase our customer focus, we have appointed Dr. Markus Tacke as Division CEO for Surface Solutions and have nominated both Division CEOs, Markus Tacke and Georg Stausberg, as members of the Executive Committee,” added Dr. Fischer. “We are excited that Markus has joined the team. He has over 25 years of experience in the energy sector and a track record of successfully transforming industrial businesses to generate profitable growth. Georg has been leading Manmade Fibers since 2015. He is responsible for successfully turning around the business and will continue driving its future growth. As recovery in our surface solutions markets continues to be highly uncertain, our focus remains on steering Oerlikon toward becoming a more cost- and capital-efficient company, delivering sustainable mid-term profitability.”

Group performance in Q3 2020

Group order intake declined by 17.3% year-over-year to CHF 518 million and Group sales decreased by 6.4% to CHF 593 million, partly due to adverse currency movements. At constant exchange rates, Group sales were CHF 619 million. In the challenging environment, Group sequential sales improved by 16.4% (Q2 2020: CHF 510 million) in the third quarter, driven by sales growth in Manmade Fibers and the recovery in automotive for Surface Solutions.

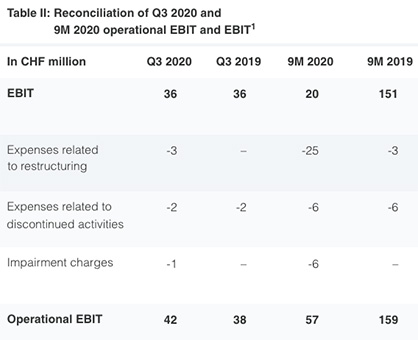

Operational Q3 EBITDA was CHF 92 million, or 15.6% of sales, representing a year-over-year improvement of 210 basis points. Compared to Q2 2020 (CHF 57 million), operational EBITDA in the third-quarter of 2020 improved by 63.6%. Q3 operational EBIT was CHF 42 million, or 7.0% of sales (Q3 2019: CHF 38 million; 5.9%). The margin improvements are attributed to the benefits from the restructuring and cost actions consequently executed by the Group.

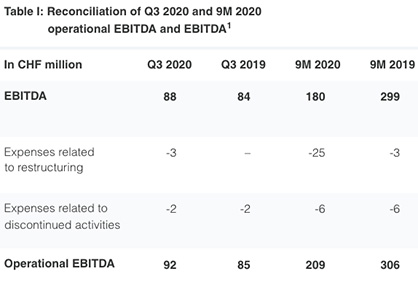

Group Q3 EBITDA was CHF 88 million, or 14.8% of sales (Q3 2019: CHF 84 million, 13.3%), and EBIT was CHF 36 million, or 6.0% (Q3 2019: CHF 36 million, 5.7%). The reconciliation of the operational and unadjusted figures can be seen in the tables below.

Successfully delivering on restructuring and productivity programs

Oerlikon has consistently implemented the structural and productivity programs and is ahead in executing the plan. The structural and cost out programs are focused on streamlining headquarters and support functions globally, restructuring Surface Solutions and rightsizing the additive manufacturing business. As of the end of the third quarter, more than 650 of the targeted 800 headcount has been reduced, of which around 40 are based in Switzerland and Liechtenstein.

In the first nine months of 2020, operating expenses in the surface solutions business were reduced by more than CHF 165 million and capital expenditure was reduced by CHF 26 million, compared to the preceding year.

Committed to mid-term EBITDA margin target

The development in end markets remains highly uncertain, exacerbated by the pandemic and geopolitical factors. Oerlikon will continue to execute its programs consistently to strengthen its core and competitive position. The Group expects the structural programs to deliver an annual run-rate of savings of around CHF 70 million, which will drive operating profitability toward the Group’s committed mid-term EBITDA margin target of 16% to 18% when markets recover.

Further empowering operational businesses: Division CEOs become members of the EC

Effective January 1, 2021, the Group’s Executive Committee (EC) will be strengthened by the appointment of two new members: Georg Stausberg and Dr. Markus Tacke, who are both Division CEOs.

Georg Stausberg is CEO of the Manmade Fibers Division and has held this role since 2015. Between 2012 and 2014, he served as CTO and COO of the Division. From 2008 to 2012, Mr. Stausberg was CEO of the Business Unit Oerlikon Neumag. Mr. Stausberg graduated from the RWTH Aachen University, Germany, with a degree in Mechanical Engineering (Dipl.-Ing.).

Dr. Markus Tacke has been appointed CEO of the Surface Solutions Division, effective October 1, 2020. Dr. Tacke has over 25 years of leadership experience in the renewable energy and gas turbine industries and is highly recognized for his ability to reposition and develop businesses. Before joining Oerlikon, he was CEO of Siemens Gamesa Renewable Energy S.A. from 2017 to 2020. Prior to that, Dr. Tacke held a number of leadership positions within Siemens’ energy businesses, the last of which being CEO of their Wind Power and Renewables Division. Dr. Tacke holds a Mechanical Engineering Degree from the Technical University of Darmstadt, Germany, a Master’s Degree in Engineering from Cornell University, USA, and a PhD from the Technical University of Darmstadt, Germany.

Manmade Fibers Division

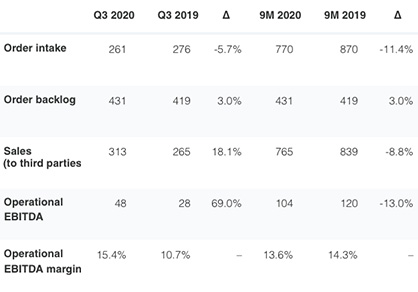

Key figures of Manmade Fibers Division as of September 30, 2020 (in CHF million)

The Manmade Fibers Division delivered another quarter of strong and stable results. Sales increased by 18.1% year-over-year. Order intake was sustained at a high level of more than CHF 250 million. These strong orders and sales figures are driven by the notable recovery in the filament equipment business in China and the continued pick-up in demand for meltblown nonwoven solutions used in face mask production. The Division is on track to fulfil its planned 2020 deliveries.

The Q3 operational EBITDA margin improved by 470 basis point year-over-year to 15.4% as a result of higher sales. Operational EBIT was CHF 40 million or 12.9% of sales. The Division’s unadjusted Q3 EBITDA was CHF 48 million, or 15.4% of sales (Q3 2019: CHF 28 million, 10.7%), and EBIT was CHF 41 million or 13.0% of sales (Q3 2019: CHF 22 million, 8.4%).