#Research & Development

Textile daylight management when the winter sun is at an angle

Daylight enhances well-being and has many advantages over artificial lighting. Sensible daylight management can therefore increase the ability to perform and concentrate. As less artificial light is required and solar gains and losses are used for room air conditioning, daylight management also saves energy.

Textile daylight systems influence the incidence of light and are mainly designed to be movable. Internal systems include, for example, roller blinds, folding blinds and curtains. External systems are external venetian blinds, awnings and screens that are guided in front of the façade. The DITF can precisely measure daylight behavior in its light and dark laboratories - even beyond existing standardized test methods.

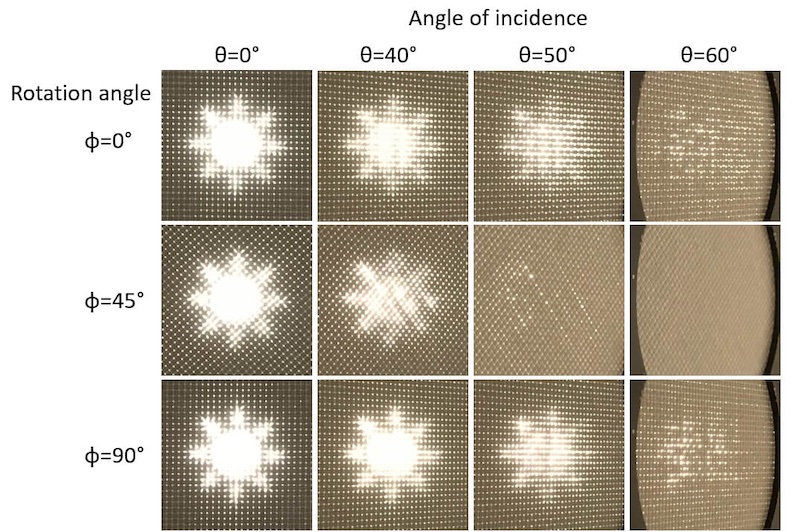

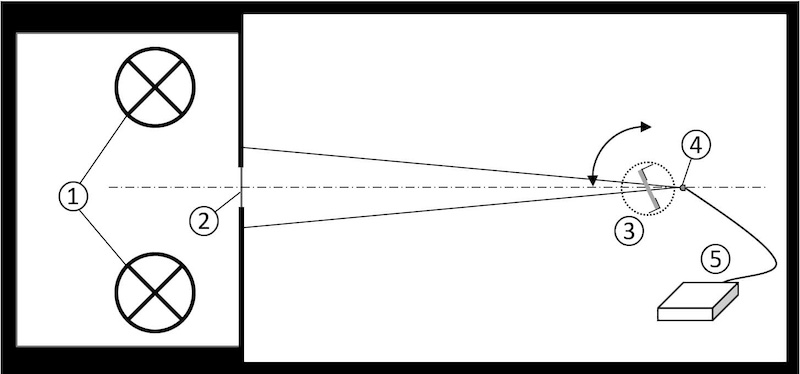

A test method developed in Denkendorf allows the glare control of solar protection devices to be re-evaluated and has been included in the standard to determine the cut-off angle. This cut-off angle describes the extent to which a solar protection device can block the transmission of direct light from a certain angle of incidence. In the currently valid standard, glare control is quantified using the two characteristics of normal and diffuse light transmittance. For solar protection devices with an openness coefficient of 1-3 %, a higher glare control class can be achieved. This applies to cut-off angles of 65° or less. The cut-off angle is determined by an angle-dependent measurement of the direct light transmittance. During the test, the solar protection textile is rotated in a modified test sample holder from the zero point until the direct light transmittance falls below a defined threshold value. This process is repeated after a gradual azimuthal rotation of the test sample, in other words a rotation of the textile in the test sample holder. Depending on the symmetry properties of the sample, up to 29 individual measurements may be required to determine the cut-off angle.

At the DITF, testing and development facilities for other photometric requirements such as incident light, self-luminous textiles and light-conducting textiles are available for industrial product developments.