#Man-Made Fibers

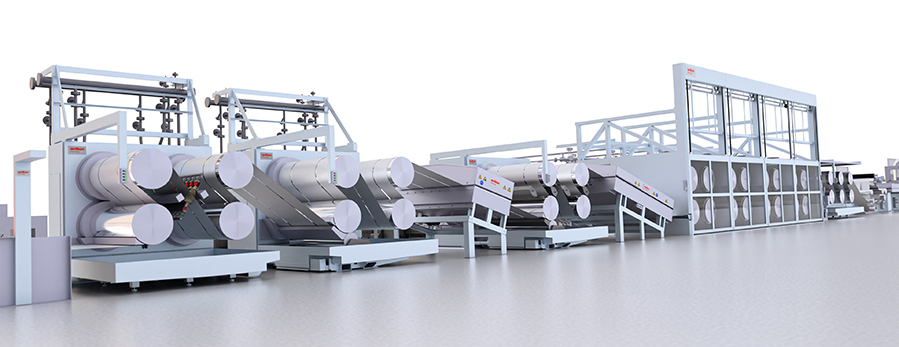

EvoSteam staple fiber process from Oerlikon Neumag bluesign® verified

All relevant process data was compared with the conventional drawing process and analysed. The results are impressive: "I am delighted that, following intensive development work on the new EvoS-team process, we have been able to reduce the total energy consumption for steam and electricity by up to 8%. In addition to reducing production waste by up to 50%, we expect to save around 3.2 million litres of water per year. For the operators of our plants, these are considerable cost savings while at the same time reducing impact on the environment by reducing the CO2 footprint by around 6%," says Dr Friedrich Lennemann, Head of Technology Development at Oerlikon Neumag, summarising the result. By receiving the bluesign® VERIFIED DATA label, Oerlikon Neumag is not only emphasising its commitment to sustainability. All polyester staple fibers produced with the EvoSteam process will actively contribute to the bluesign® SYSTEM in the future.

bluesign® VERIFIED DATA

For the EvoSteam process, Oerlikon Neumag received the bluesign® VERIFIED DATA label for the first time. The label includes the verification of impact data such as water, spinning preparations, thermal and electrical energy as well as the CO2 footprint by means of a plausibility check of the supporting records for the EvoSteam draw line, the central element in the EvoSteam process. The reported data was assessed as 2.1 - fair - in accordance with the defined methodology.

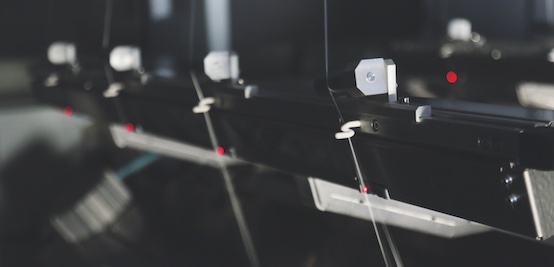

EvoSteam process for sustainable staple fiber production

The EvoSteam process was presented to the global public for the first time at ITMA 2023 in Milan. Visitors to the trade fair spoke of a major development step, as the EvoSteam process dispenses with liquid baths. The function of the immersion bath is assumed by a carefully-coordinated setup of godets and pulsed spray nozzles. With this, the moisture is metered precisely and added according to the needs of the process. This completely dispensing with liquid baths generates significant savings in terms of water, energy and finishes, while also increasing occupational safety and cleanliness at the production line.