#Spinning

Savio customer days across Asia

SOLO Seminar has been attended by 80 people, representing about 25 spinning mills equal to 2,3 Mio ring spinning spindles. Central Java in the recent years has became an investment destination for the textile industry, with its lively textile areas like Solo, Semarang and Pakalongan.

The symposium has been characterized by a great interest on the new winding concept of ECO PULSARS machine. During the open discussion, following the presentation of SAVIO Group and product range made by Mr. Mario Puppi, Regional Sales Vice President, the customers focused their questions mainly to fully automatic machines and to the link version.

BANDUNG seminar has been attended by 90 people, representing about 40 spinning mills equal to 3 Mio ring spinning spindles, with participants also from Jakarta area. Bandung is the largest textile spinning area in Java, followed by Jakarta and Central Java (Solo). The symposium had as its main objective the presentation of the new SAVIO automatic winder named ECO PULSARS, following the official launch in Milan. Extraordinary interest aroused among the entrepreneurs and technical people. The new concept of winding developed by SAVIO satisfies the most sensitive market demand that is energy saving. Most of the questions raised by the audience were focused to the technical solutions and software adopted by SAVIO in the new ECO PULSARS machine, in comparison to the actual winding technology.

VIETNAM Saigon, March 1st 2016 Hanoi, March 3rd 2016

SAIGON seminar has been attended by 100 people, representing about 30 spinning mills equal to 2 Mio ring spinning spindles. VINATEX delegation from Ho Chi Minh City was also present, together with several customers arrived from all South area of Vietnam. The data shown about the relevant performances of the running ECO PULSARS machines in different market of the South East Asia area, have attracted great interest on the competent audience.

HANOI seminar has been attended by over 100 people, representing 35 spinning mills equal to 2,5 Mio ring spinning spindles, with participants also from Hue and Nha Trang area.Vietnam has become in the latest few years one of the most important textile market in the world, mainly due to foreign investments from China,Taiwan and South Korea. The Seminar had the main target to launch to Vietnamese market the new SAVIO automatic winder model ECO PULSARS.The energy saving up to 30% on the new machine Eco PulsarS machine, has created a lively interest on the present customers.

Savio took the opportunity to refresh and update Pakistani customers on the developments and new implementations at SAVIO through two Symposiums in the two major cities. The response from customers has been overwhelming, in Karachi 180 people attended the presentation, while in Lahore 300 people came to be highlighted about latest innovations.

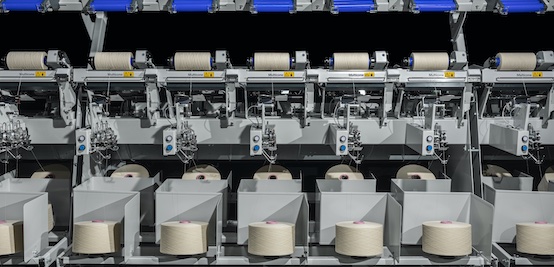

Mauro Moro, Commercial Director, presented the major winding innovation, Eco PulsarS automatic winder. He explained the technical advantages of the machine to the participants: Eco PulsarS is designed for optimum productivity, unprecedent power savings, high quality packages and utmost flexibility.

Davide Mercuri, Regional Sales Vice-President, during his presentation talked about the Two-for-One Twister generation, SIRIUS, especially focusing on model type Sirius Electronic Drive System. This version allows to set all working parameters via machine PC, thus reducing the machine set-up time and introducing a simple and direct way to change any setting.

INDIA Ahmedabad, April 26th 2016 Rajkot, April 27th 2016 Coimbatore, April 30th 2016

Savio Macchine Tessili and A.T.E. organized a series of Customer Days across India to announce tie-up between the two companies. A.T.E. has become the sole selling agent for Savio's automatic winders and two-for-one twisters in India from April 1st, 2016. Mr. G.V. Aras, ATE Director, welcomed the guests with an opening speech.

Mr. Franco Bonello, Managing Director of Savio India Ltd, outlined the activities at the Savio's Coimbatore factory, and the latest developments in Savio India's best-sellers TFOs - Sirius and Cosmos. A key highlight of the events was the presentation made by Mr. Valter De Carli, Regional Sales Vice President of Savio, on the recently launched automatic winder Eco PulsarS. The presentation also highlighted the state-of-the-art TFO model Sirius with EDS technology (Electronic Drive System) and the new energy efficient family of spindles. The Q&A session at the end of each event showed the keen interest of the participants in the Savio product range.

The first three events saw a participation of almost a thousand guests.