#ITMA-Asia + CITME-2016

DORNIER weaving machines for “green technologies” and high fashion clothing at the ITMA Asia + CITME 2016

Apart from the production of textile fabrics, focus will be on weaving high-quality materials for clothing. Chinese and Asian textile manufacturers will also be able to see how they can manufacture reliable prime quality, combined with high productivity, in the fast growing clothing market segment. DORNIER weaving machines show unique performance and process reliability, especially in these production segments with the highest demands on the fabrics. This results from consequent exchange of ideas with customers, the imagination of DORNIER engineers as well as the quality of the production in Germany. After presenting the rapier weaving machine P2 type TGS at the ITMA 2015 in Milan, DORNIER will now present a further new type of rapier weaving machine at the ITMA Asia + CITME 2016 for the first time. The new P2 type TGV combines the reliability of the previous P1 PTV model with the future-oriented modular P2 machine concept. Apart from that, DORNIER will show an air-jet weaving machine of the latest generation A1 type AWS. An air-jet weaving machine in Jacquard version can be seen on Stäubli’s exhibition stand. Each of these machines will prove its performance capability through the production of especially demanding fabrics in compliance with DORNIER’s basic principle “Quality creates value”. Peter D. Dornier, chairman of the executive board, on the participation at the ITMA Asia + CITME: “We are now looking forward to the ITMA Asia + CITME after a very successful ITMA 2015. The 13th Chinese FYP (Five Year Plan, 2016 - 2020) has ambitious goals for the textile industry. The target is an industrial transformation to cutting-edge technology. And it demands “green technologies”, which means environmental protection is becoming more and more importance. This fits perfectly to DORNIER since our special strengths lie in these areas. We want to support Chinese weavers with our weaving machines, our know-how and reliability as a German family company to reach their ambitious goals and to help them success- fully master the transformation. Our weaving machines stand for technological leadership and we have been first choice and very reliable partners for growth and success for many years now, and will continue as such during the Chinese structural change with, for example, “green technologies”, higher productivity and highest quality fabrics”. DORNIER will present the following machines and applications at the ITMA Asia:

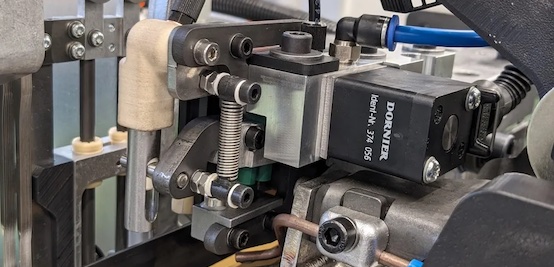

The demands of the Chinese consumer-oriented middle class for high-quality clothing have risen strongly over the last years. Various studies prophecy that this trend will grow further. This opens up large opportunities for Chinese weavers to produce superior quality for the clothing market and to be successful in this segment. The special challenge here is to produce a fabric with this quality whilst meeting the most demanding requirements with high productivity. The DORNIER air-jet weaving machine achieves this with a gentle filling insertion (“senza pelosità”, i.e. no fabric hairiness) combined with automatic filling break clearance. But DORNIER would not be DORNIER if productivity and quality were not continuously driven on. In industrial use, this has already been successful in the unique DORNIER quality by promi- nent Italian wool weavers with a speed of up to 1,000 rpm. The heart of the DORNIER “weave-by-wire” technology is the patented drive concept DORNIER SyncroDrive®. It is a very low maintenance weaving machine drive based on servomotors without clutch-brake unit. The close of shed is adjustable electroni- cally during weaving via DORNIER ErgoWeave®, style data are archived and therefore reproducible.The newly developed nozzle concept that allows a gentle acceleration of the filling thread and the high-performance carbon shafts further more reduce vibrations during shedding.

Pic: DORNIER air-jet weaving machine A1 type AWS 4/J G with a nominal width of 280 cm in combination with Stäubli Jacquard machine LXLArticle: Airbag fabric (Stäubli stand: Halle 3, stand B111)

At the Stäubli stand, an air-jet weaving machine type A1 produces an airbag fabric “one piece woven” as a hollow body. This very special demand is mastered optimally by the Jacquard weaving machine with its very high flexibility. 12,228 lifting hooks are used here. The machine has the patented DORNIER SyncroDrive® fitted as standard.During Jacquard weaving with the DORNIER SyncroDrive®, the weaving machine and Jacquard machine have separate drives and servomotors whereby the cardan shaft is not required. The connection runs via an electronic shaft. The very rigid and low vibration drive concept reduces the mechanical load as well as wear in the complete shedding area. The forces acting on the system as well as the energy consumption are drastically reduced.This type of airbag with small packing size is used, for example, as protection against side impacts. Protection of limb and life are the most important aspects of sustainability. A lot more can be done for passenger protection in lower and middle class vehicles, even in Europe and the USA. This is the reason why airbags remain a growth market, especially for the Asian market. Here, the A1 in Jacquard version with its high productivity and extreme process reliability offers optimum possibilities. Airbags of top-quality are produced in series while meeting economic and ecological criteria. DORNIER SyncroDrive® The patented DORNIER SyncroDrive® is a particularly low maintenance drive.The basis are servomotors with direct controlling but without a clutch-brake unit. This drive concept permits to change the close of shed timepoint during weaving. The very rigid and low vibration drive concept reduces mechanical load as well as attrition in the whole shedding motion and in this way ensures fewer warp breaks.Systems equipped with DORNIER SyncroDrive® insert the yarns very gently. Service life is prolonged and operating costs reduced. Lower costs, highest functional reliability and an outstanding fabric quality raise weaving with DORNIER SyncroDrive® to a high level.