#Knitting & Hosiery

Innovations of today for the generations of tomorrow

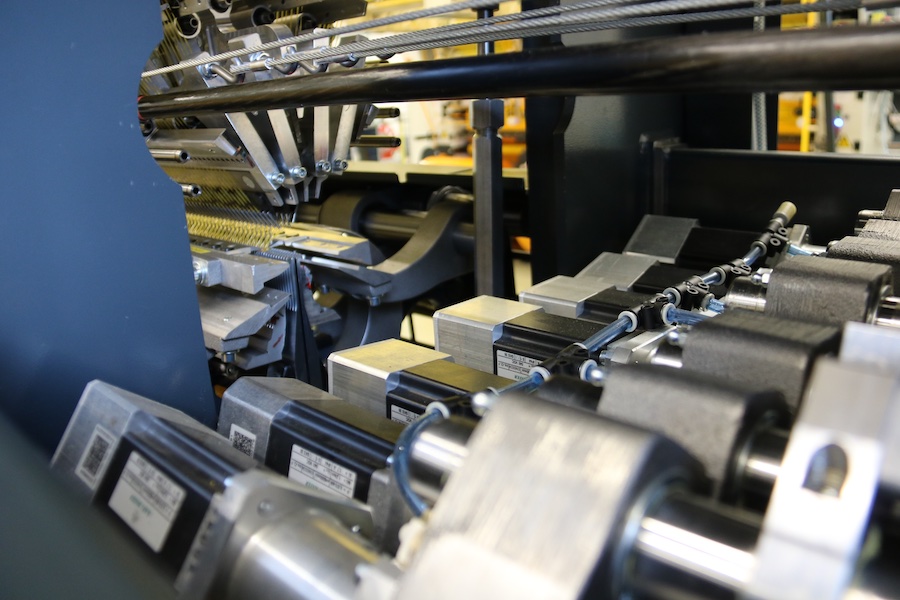

Short development cycles, frequent pattern changes, and maximum efficiency – even with small batch sizes: Today's global fashion and apparel market demands more flexibility than ever before. High-performance warp knitting machines with compound needles (HKS) and EL pattern drive are KARL MAYER's answer to this challenge.

KARL MAYER is celebrating an anniversary this year: on 30 November 1990, the first warp knitting machine with electronic guide bar control, the KS 4 EL, was delivered – another milestone for patterning. As early as 1980, the SU gearbox with the MRS42SU had initiated the transition from mechanical chains to digital data.

ITMA ASIA 2025 exceeded all expectations for KARL MAYER – above all thanks to the strong interest from India: around 30% of the qualified discussions were held with partners from this traditional textile country. The response underlines the growing importance of the Indian market, which could become the second largest sales region for KARL MAYER after China. The warp knitting industry in particular is developing dynamically.

Getzner Textil is one of KARL MAYER’s first customers to use PROSIZE with CASCADE. The innovative weaving specialist has tested the steam and condensation system by KARL MAYER and determined the energy savings it achieves. Karl-Heinz Vaaßen, Head of Textile Drying at KARL MAYER, assisted Getzner Textil’s production specialists both with the tests and with all questions relating to CASCADE. In a conversation with Werner Egger, Head of Weaving, and Thomas Rossi, Head of Warp Preparation at Getzner Textil, he learnt more about the system’s benefits for his customer.

Leading flat knitting solutions provider SHIMA SEIKI MFG., LTD. of Wakayama, Japan, together with its Hong Kong and Chinese market subsidiary SHIMA SEIKI (HONG KONG) LTD., will exhibit at the ShanghaiTex 2025 exhibition (Booth No.: Hall N3, Booth A20) held in Shanghai, China this month. This marks the return of SHIMA SEIKI to ShanghaiTex after a 14-year hiatus, its last exhibit at the show having been in 2011.

From December 16 to 19, 2025, the global textile industry will gather at ShanghaiTex at the Shanghai New International Expo Center (SNIEC), where Groz-Beckert will present its latest highlights and innovations across its five product areas – Knitting, Weaving, Nonwovens, Sewing, and Spinning – at Hall N3, Booth A05.

Mayer & Cie., the long-established German manufacturer of circular knitting and braiding machines, will cease operations after its international search for an investor ended without success. The company, based in Albstadt-Tailfingen, had been undergoing insolvency proceedings in self-administration since its filing on 23 September 2025. As Schwarzwälder Bote reports, the insolvency court has now formally opened the proceedings, triggering the decision to wind down the business in an orderly process.

ITMA ASIA in Singapore was a resounding success for KARL MAYER, exceeding all expectations. The company welcomed visitors from 39 countries and held around 570 expert discussions. Most guests came from India, followed by China, Indonesia and Pakistan. The exchange with them was both well-founded and targeted. Conversation topics ranged from investment projects and new technologies to opportunities for cooperation and business expansion.

The 38th International Cotton Conference Bremen, to be held on 25-27 March 2026 in Bremen’s parliament building on market square, once again sends a powerful signal for professional excellence and international dialogue. The focus is on the latest market trends and technical innovations throughout the entire value chain – from agriculture and quality assurance to processing and the circular economy. With its high-calibre speakers, the conference remains an indispensable forum for anyone involved in shaping the cotton industry scientifically, technically, or economically.

Since 2024, under new ownership and leadership, Circulose has set a renewed strategic direction focused on securing long-term commitments with partner brands to bring CIRCULOSE® back to market at scale. This strategy has proven successful.

When everyday materials are pulled, they stretch or elongate in the direction of the pull and become narrower in cross-section. We can also observe this property in two-dimensional textiles. Auxetic structures behave differently here. They have the striking property of not changing under tensile stress or even increasing their width or thickness. These properties are advantageous, for example, in protective textiles or textile filter media. The DITF are researching auxetic fabrics for various applications.

The process, which is both economically and environmentally sustainable, has enabled the production of an underwear set made from 100% recycled nylon and LYCRA® fibre in a closed-loop system.