#Sustainability

Lindauer DORNIER continues to rely on solar power

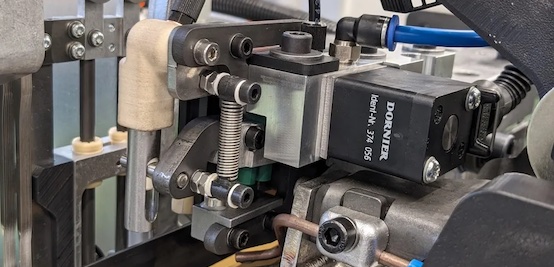

With a maximum output of up to 880 kWp (kilowatt peak), the new photovoltaic system can generate up to 880,000 kWh of solar power per year under optimal conditions. This amount could supply around 220 average four-person households with electricity for a year. Spread over six roofs and with a total area of around 4,000 m², the new system is the largest rooftop system in the district of Lindau, according to Energie-Atlas Bayern. ‘The project was a bit tricky because the feed-in points are spread across the entire factory premises, some of which are listed buildings – but the high planning effort paid off,’ says Franz-Peter Matheis, CFO at DORNIER. DORNIER uses the majority of the solar power generated for the production of its air-jet and rapier weaving machines. The surplus electricity is fed into the public power grid and thus also supplies private households in the region with environmentally friendly solar energy. ‘Our thanks go above all to Stadtwerke Lindau, who have supported us at all times, especially with the fast processing and certification of the system,’ says Matheis. If the company's own electricity supply is not sufficient, it obtains 100% green electricity from hydropower by cooperating with Stadtwerke Lindau as a regional electricity provider.

Aim: to cover energy needs entirely from renewables

The new photovoltaic system is part of large investments that DORNIER has recently made to strengthen sustainability and secure the future of its two production sites in Lindau and Esseratsweiler. In addition to the photovoltaic system on the roof of the film stretching system production hall in Esseratsweiler, which was commissioned in 2022, this also includes investments in the modernisation of the machinery, the expansion of digitisation, the self-supply of nitrogen (which eliminates CO2-intensive transport) and the construction of a new training centre for up to 75 trainees and dual students in Lindau.