#Techtextil 2017

More sustainability in agriculture with Lenzing™ fibers

The Lenzing AG is investing approximately EUR 15 mn to expand its production capacity for premium viscose fibers at its site in Lenzing, Austria. This strategic investment is part of the recently announced investment program of EUR 100 mn in total to secure the long-term competitiveness of Lenzing’s Austrian production sites. The capacity expansion reinforces the company’s commitment to providing sustainable solutions to the global hygiene market. It also strengthens the company's role as a trusted provider of high-quality fibers for feminine care applications.

In the first nine months of 2025, Lenzing AG recorded revenue growth and higher EBITDA, but a market-driven volatile third quarter. This performance reflects the effects of ongoing market volatility, tariffs and geopolitical uncertainties. Nevertheless, the medium to long-term outlook remains positive.

Lenzing AG has once again taken first place in this year's Hot Button Report published by the Canadian non-profit organization Canopy. With 34.5 out of 40 points and no known risk of sourcing from ancient and endangered forests, Lenzing remains one of the most sustainable companies in regenerated cellulose fiber production – setting a benchmark for responsible business practices in the textile and nonwovens industries.

Lenzing AG, a leading provider of regenerated cellulosic fibers, refined its strategy to strengthen its global positioning and competitiveness. With this step, the company responds to the ongoing challenges in the global textile and nonwovens markets as well as geopolitical changes. Cornerstones of the refined strategy include focusing on high-performance fibers, enhancing operational efficiency and asset footprint optimization, which should further unlock the company’s full value creation potential.

The Advanced Recycling Conference (ARC) 2025 brought together nearly 220 experts from 28 countries to spotlight pioneering advancements and foster industry collaboration in recycling across diverse waste streams including plastics, textiles, automotive and other materials.

Navis TubeTex, a global leader in advanced dyeing and finishing machinery solutions, is pleased to announce a new partnership with Icomatex (www.icomatex.com), a respected European manufacturer of high-quality stenters and textile finishing equipment. Under this agreement, Navis TubeTex will exclusively represent the Icomatex stenter line in the United States.

ADVANSA has introduced ADVA®tex, a new filling fibre made entirely from recycled pre-consumer textile waste, positioning the material as a significant step forward in textile-to-textile (T2T) recycling. The fibre is designed for use in duvets, pillows, mattresses, and furniture applications and is available in three versions.

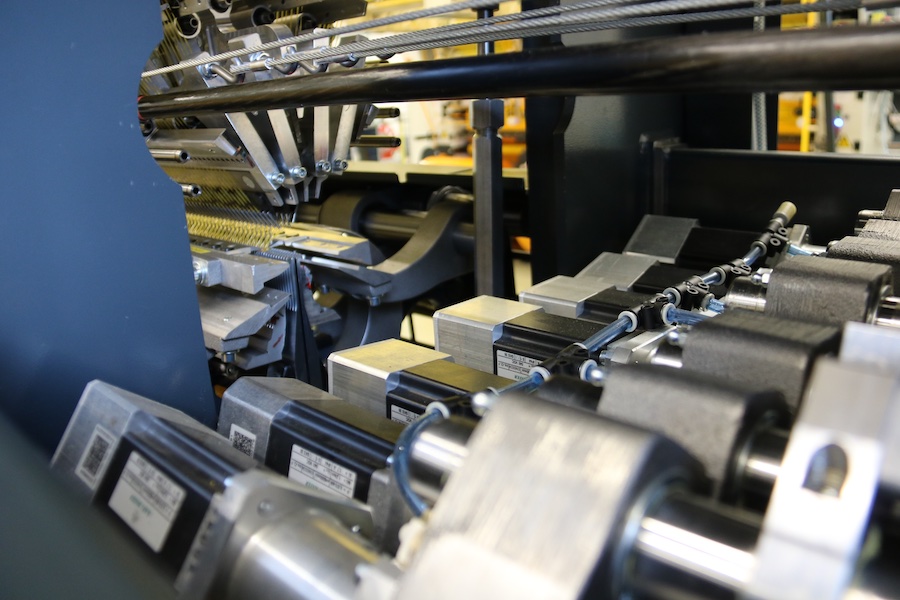

KARL MAYER is celebrating an anniversary this year: on 30 November 1990, the first warp knitting machine with electronic guide bar control, the KS 4 EL, was delivered – another milestone for patterning. As early as 1980, the SU gearbox with the MRS42SU had initiated the transition from mechanical chains to digital data.