#Techtextil 2017

DiloGroup looks back at a successful Techtextil 2017

Technical textiles – a dynamic high tech sector

New machine techniques and technologies, interesting products and spectacular visions of the future: During all 4 days of Techtextil, international visitors crowded the fairground to discover high-tech textiles used in applications like foldable textile floodlights, smart knee braces, warming or cooling fashion and clothes with integrated LED lights, incombustible fibres, bicycle frames made from carbon fibre and textile membranes for stadium roofs. Most Techtextil visitors came from Germany, Italy, France and Turkey and to the Texprocess from Italy, Romania and Portugal.

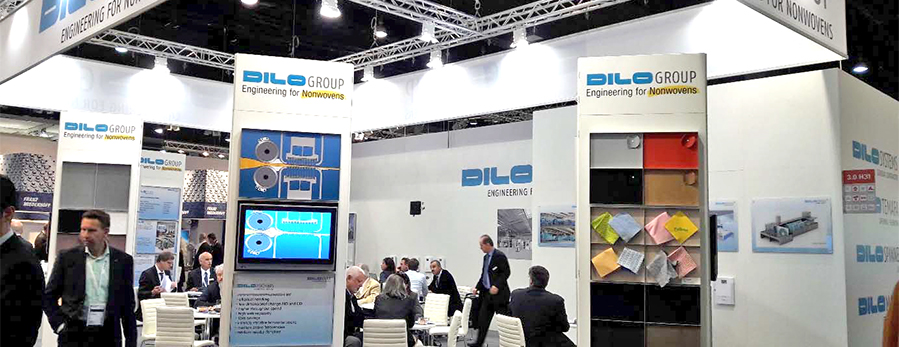

DiloGroup informed about interesting themes and topics and, a great number of customers and interested parties paid a visit to the DILO booth. DiloGroup, the leading group in the sector of staple fibre needling lines, who realized record turnovers in 2015 and 2016, took the chance to once again extensively inform about its equipment portfolio.

Staple fibre needling lines which consist of fibre preparation, i. e. opening and blending equipment, card feeding and cards as well as crosslappers and needle looms, were the main topic of discussion on the fair.

One important aspect for users is the joint drive and automatization technique which is used to interconnect the whole system and which complies with the demands of modern interlacing and smart production.

Customized production lines for each purpose and value are designed, manufactured, delivered and put into operation by DiloGroup. Service and high availability of spare parts support the high operational availability of DILO needling lines.

DiloGroup not only presented its standard universal lines at Techtextil 2017 but also the latest innovations of the DILO portfolio which provide increased manufacturing efficiency, improved endproduct quality and greater productivity aided by the degree of automation.

The machines of DiloGroup are used in all the most important sectors such as automotive, floor coverings, synthetic leather, geotextiles and filtration.

The new technology “HyperTex” using an inline yarn layer to produce multi-layer reinforced nonwovens has been developed especially for filter media, geotextiles and roofing material. This new approach has been acknowledged with great interest.

In the field of special fibres processing as used for carbon composite materials made from recycled fibres much headway has been made. Compact special lines for product development using recycled carbon fibres are now successfully operated.

In addition, DiloGroup informed about wide carding systems with high web speeds used in water entanglement lines. DiloSystems offers such special carding systems in working widths exceeding 5 m and web speeds of more than 400 m/min.

The great number of customers and interested parties showed once again that the development potential for technical textiles, especially for needled nonwovens and composites, has not yet been fully utilized.