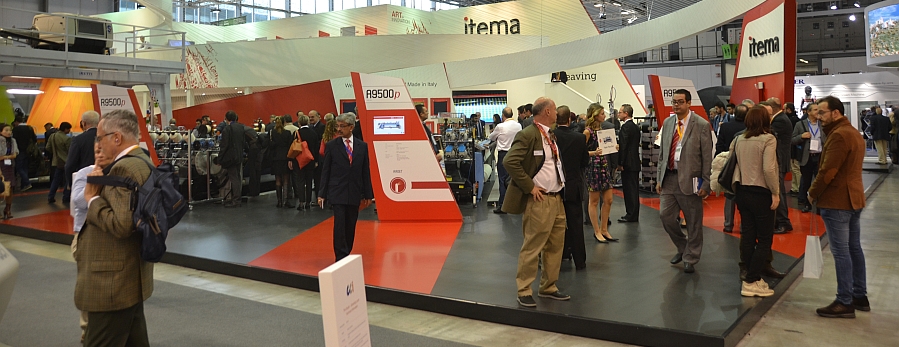

#Techtextil 2017

Itema offers excellent machines for weaving technical textiles

Technical textiles are going to take even more center stage and become ever-more ubiquitous in architecture and green buildings, automotives, smarter cities, intelligent and energy efficient devices, furnishing and athletic, workwear and fashion apparel. And we have yet to understand the full scale of the immense potential to be harnessed from the uber-connectivity of the all-enthralling phenomen of the so-called Internet of Things.

As a partner and weaving machinery supplier to textile manufacturers worldwide, Itema strongly believes in the endless opportunities and the growth potential of technical applications, and has therefore dedicated its twin R&D departments to develop the necessary technology to anticipate weavers’ requirements.

The textile machinery maker already derives a growing portion of the overall turnover from sales of weaving machines specialized in technical textiles applications. Asia, Europe and North America and just among some of the strategically important areas where the adoption of Itema’s technology for technical textiles is on the rise. A significant number of weaving machines by Itema are used for technical textiles, like geotextile, coating, filter fabrics to list just a few applications.

Itema is uniquely positioned to offer technical textile manufacturers the top three technologies for weft insertion: Rapier, Airjet and Projectile, in what is the most comprehensive portfolio on the market today for technical applications. Itema is the unique partner in the market providing dedicated best-in-class technological advancements and the strongest textile expertise. Let’s consider the matter and discover together which are the strongest advantages of the Itema weaving machines for the growing technical textile applications markets worldwide.

Projectile Weaving Machine P7300HP V8

For the projectile machine, the legendary and unique P7300HP, technical fabrics are its specialty due to the unparalleled versatility and reliability of its weft insertion system. The unmatchable uniqueness of the positive weft transfer consists in the single insertion driven by the projectile, which catches the weft and carries it directly with no exchanges, providing unparalleled efficiency.

The P7300HP V8 continues to harness great interest from projectile weaving aficionados and represents an unbeaten and unbeatable benchmark for those looking to weave the very widest fabrics (over 6 meters) and high-specialty materials, such as agrotextile, geotextile and carpet backing fabrics. Still today, when it comes to weave tape yarns, the Itema projectile weaving machine provides the highest performance compared to all the other technologies in the market.

Rapier Weaving Machine R9500

The R9500 loom is by far the most successful rapier loom in the recent history. The continuous roll-out of customized special versions tailored for technical applications, including OPW Airbag, Fiberglass, Bolting Cloth, among others, the wide weaving width up to 540 cm, as well as dedicated devices for each application make the R9500 by Itema the perfect machine for the manufacture of the full range of technical textiles, including ones with the finest monofilament yarn, multifilament yarn with high tenacity, and multiple pick insertion fabrics.

Thanks to extensive in-house trials, led by the most experienced and skilled Itema technicians in cooperation with one of the European leading weavers of fiberglass, allowed the Company to develop an advanced, high-performance version of R9500 to weave this demanding fabric. Used in many electronic and industrial applications, fiberglass needs to be woven on a sensitive and, at the same time, sturdy weaving machine. The rapier R9500 designed to weave fiberglass features a brand-new Light Weight Back-Rest Roller ensuring high reactivity, able to compensate the lack of elasticity characteristic of this specific yarn. Furthermore, specific to weave fiberglass is the Rotary Fabric Bar, designed for open construction patterns to avoid fabric distortion.

Flexibility and versatility are guaranteed by the rapier weft transfer system FPA - Free Positive Approach with no guiding elements in the shed, which merges reliability with the possibility to weave the most demanding and delicate yarns. Flexibility is further increased due to the Motorized Weft Cutter, which allows to adjust the cutting time weft by weft, thus leading also to a minimized weft waste. Moreover, the innovative ELD - Electronic Leno Device, unique in the industry, provides a complete leno binding at fabric sides.

The mentioned weaving features perfectly meet the requirements of other high performances fabrics: aramid and nomex, widely used in aerospace and military applications. Further optimized to weave aramid, the Itema R9500 can be also equipped with special surface weft feeders and electronic brake.

In the wide world of technical textiles, a special mention goes to automotive and mattress ticking fabrics, which demand for production is particularly growing. The Itema R9500, thanks to the FPA weft transfer coupled with the Motorized Weft Cutter, guarantees unparalleled machine performances and superior fabric Quality.

Airjet Weaving Machine A9500

The airjet A9500 inspires the curiosity and sparks the interest from real technology buffs, especially in sophisticated and demanding markets, and has already amassed important references, especially in medical applications and automotive fabrics.

Looking at specific technical applications which are growing exponentially in north-eastern Countries, the Itema airjet A9500 provides undeniable benefits, matching unparalleled performances and the highest productivity with superior textile efficiency.

When it comes to weave very high density fabrics, such as the decatizing satin fabric, dedicated devices ensure best-in-class results. The reinforced whip roller eliminates friction allowing an improved warp tension control and reducing warp stops, whilst the left and right waste selvedge assures the correct tension of the weft leading to an excellent fabric quality. Moreover, the longer dwell of the cam sley drive allows a longer weft insertion time, leading to a more efficient weft filling insertion. The Itema patented ELD - Electronic Leno Device, is the ideal solution for leno binding on high speed machines guaranteeing a perfect leno binding whilst significantly reducing operational costs thanks to its innovative design.

Itema is registering an increasing demand in airjet technology to weave fabrics for the automotive industry. Customers who chose the Itema A9500 to weave these type fabrics, reported that in this particular field what makes the Itema airjet extremely successful is again the longer dwell of the cam sley drive and, a brand-new innovation featured on A9500, the double tandem nozzles which allow to weave even the most coarse yarns at high speed.

Parachute fabrics is another main application for airjet technology, and the Itema A9500 exceeds weaver’s expectations with its elastic whip roller, a dedicated device for warp tension compensation. The double pick insertion ensures to weaving ripstop and, furthermore, the Polito nozzle guarantees high speed weft insertion and ensures unparalleled productivity.

There is a strong, undeniable momentum around technical textiles destined for growth, and it will become an increasingly important segment predicted to reach around USD 315B by 2020 (source: Gherzi). Textile manufacturers are on the verge of a big change of the technical textiles world. Only the bravest and the most forward-thinking will know how to fully embrace the full spectrum of opportunities and turn them into competitive advantages.

ITEMA is excited to be a big and growing part of this dynamic and promising market, with the right technology for all the below applications and many more in the development pipeline:

- Agrotextiles and Geotextiles

- Medical

- Furnishing

- Civil engineering and Building

- Industry

- Transports

- Apparel and footwear

- Sport and leisure time

- Automotive incl. Airbag

- Mattresses

- Carpet Backing (primary and secondary

- Protective Wear

- Conveyor Belt

- Filter Cloth

- Parachute

- Coating

- Fiberglass

- Polypropylene

- Glass fabrics

- PP-Bags and big bags

- Sails cloth / Canvas

- Awnings