#Sustainability

OEKO-TEX® launches ORGANIC COTTON certification

For verification of organic origin, OEKO-TEX®’s GMO quantification method differentiates between contamination and purposeful mixing of conventional cotton. The new certification works in compliance with several global regulations including EU REACH Annex XIV and XVII, US CPSIA (lead), EU POP regulation.

OEKO-TEX® has been testing and certifying organic cotton since the launch of OEKO-TEX® STANDARD 100 over 30 years ago. As the use of organic cotton in fashion and textiles has increased, so have the requests to call out organic cotton in OEKO-TEX® STANDARD 100 certificates. “Our response to this development is a comprehensive, independent and objective testing and certification system for textile products made of organic cotton throughout the whole production chain”, says Georg Dieners, OEKO- TEX® General Secretary. “Our goal is to enable everyone to make responsible decisions and protect natural resources. Therefore, OEKO-TEX® ORGANIC COTTON offers targeted support for companies along the supply chain. It allows them to protect human health based on a scientifically proven criteria catalogue and neutral laboratory tests. End consumers receive a reliable, manufacturer-independent product label. This means safer, organic cotton products that have been tested along the whole chain of custody - a valuable contribution to effective consumer protection.”

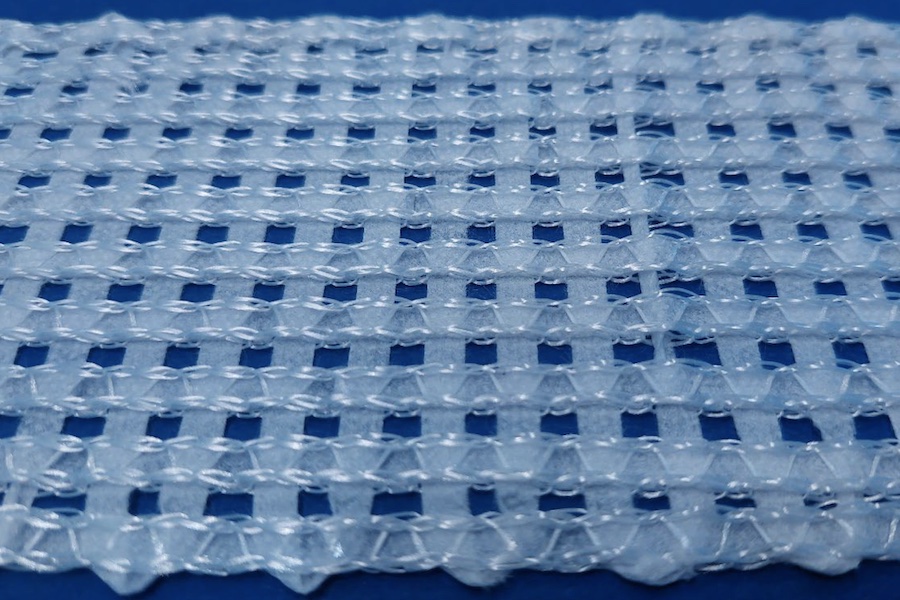

To ensure clear consumer communication, OEKO-TEX® has created a label and sub label: “ORGANIC COTTON” certifies articles and materials made of 100% organic cotton, whereas “ORGANIC COTTON Blended” certified articles must be made of at least 70% organic cotton. With proof of origin, any article containing organic cotton can still be tested for harmful substances and certified with OEKO-TEX® STANDARD 100. The certification can be communicated with the OEKO-TEX® STANDARD 100 label, with organic cotton stated in the certificate text. Mixtures of organic and conventional cotton are forbidden in all three certificates.

The OEKO-TEX® quantitative GMO testing method is the first method able to differentiate between intentional mixing versus unavoidable contamination (e.g. from fibre flight) with conventional cotton. For the launch of ORGANIC COTTON, OEKO-TEX® has set a limit of <10% GMOs. The intention is to gather knowledge and experience through incoming data, then adapt the limit value to further develop and improve the certification.

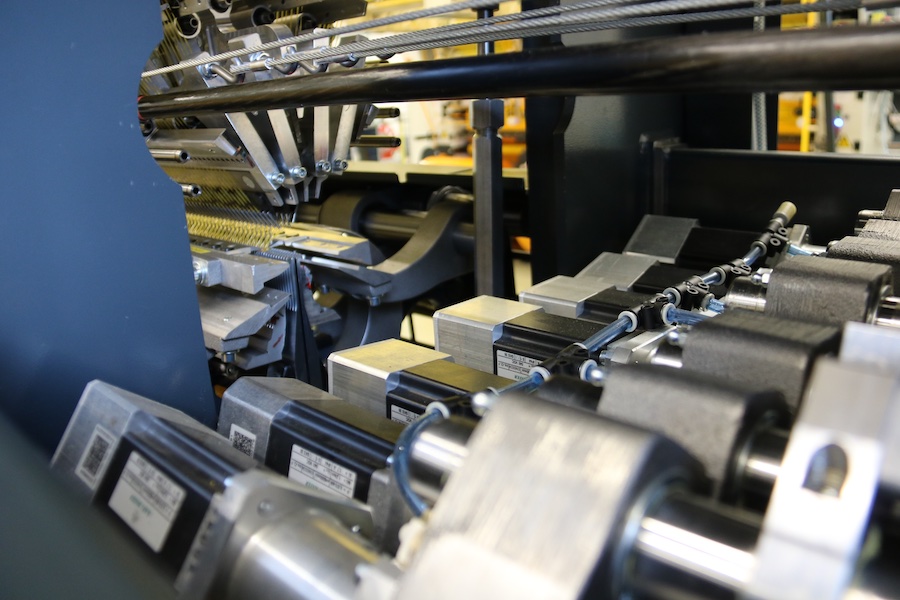

To ensure organic farming practices at the farm level, OEKO-TEX® ORGANIC COTTON requires a certification according to the IFOAM (International Federation of Organic Agriculture Movements) family of standards. The full test program of the OEKO-TEX® STANDARD 100 is carried out to ensure product safety. Additional tests for GMOs and pesticides are carried out to prove organic farming. In case of a failed qualitative GMO test, the quantitative GMO test checks if the failure was due to contamination or intentional mixing. In addition to verification of all documents and laboratory testing of samples, the responsible OEKO-TEX® testing institutes conduct on-site visits prior to issuing the certificate.

Starting with the ginning phase, each change of ownership requires an OEKO-TEX® ORGANIC COTTON transaction certificate. Along with the transaction certificate, documentation proving the transaction, such as relevant invoices and delivery slips, plus all ORGANIC COTTON certificates, must be submitted. These steps are repeated annually with a focus on traceability. To prevent fraud, OEKO-TEX® maintains a secure database with all transactions.

The OEKO-TEX® modular system offers multiple synergies for manufactures and brands, e.g., using OEKO-TEX® ECO PASSPORT certified chemicals can reduce the testing effort for an OEKO-TEX® ORGANIC COTTON certification. The focus of ORGANIC COTTON is to ensure organic origin via GMO and pesticide testing, as well as the chain-of-custody through transaction certificates and consumer safety via testing for harmful substances. All OEKO-TEX® customers must comply with fundamental social criteria as part of the OEKO-TEX® Code of Conduct. To cover social criteria in the full extent, OEKO-TEX® ORGANIC COTTON can be combined with OEKO-TEX® STeP facility certification, which is also part of OEKO-TEX® MADE IN GREEN product label. The latter enables full supply chain transparency for end-consumers via QR code, which guides consumers to the OEKO-TEX® label check.