#Knitting & Hosiery

Movement without gears. Patterning without limits.

KARL MAYER celebrates 35 years of EL pattern drive

SU drive: cassette instead of chain

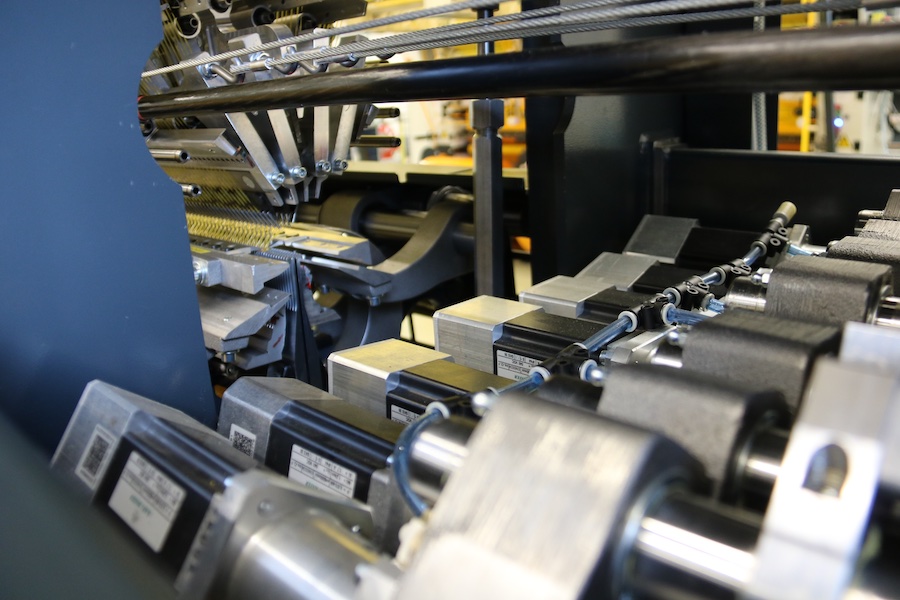

The SU drive – first introduced in Multibar Raschel machines – controlled the shogging movement of the guide bars magneto-mechanically via actuators and a microcomputer. The advantages were virtually unlimited repeat lengths, higher production speeds, less handling and shorter set-up times. Patterns could be changed in minutes instead of hours without changing chains.

Thanks to an SU drive with integrated overlap device developed in 1985, the pattern chains and discs for the guide bar control on tricot machines could also be replaced – paving the way for further electronic solutions.

EL guide bar control: motor instead of mechanics

In order to overcome the mechanical limitations of the SU drive for tricot machines, KARL MAYER developed a system with electric motors, thereby performing pioneering work.

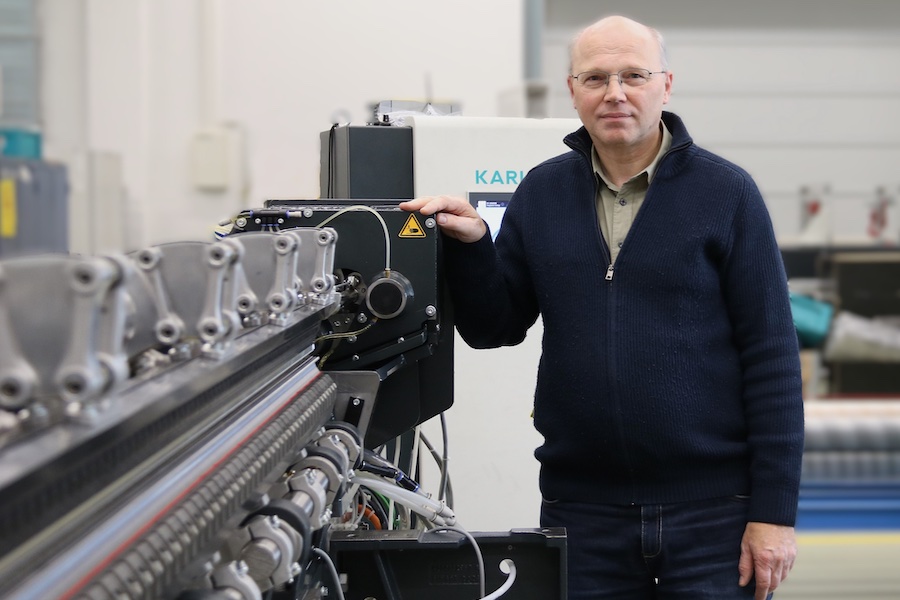

“We wanted to use electric motors to move the bars. That was completely new territory,” recalls Georg Kraus, Senior Expert Technology Development and EL pattern drive activist from the very beginning.

A test rig with asynchronous motors and ball screws showed that the new principle worked quickly, precisely and reliably.

The prototype led to the development of electronic guide bar control, and a new era began. The first KS 4 EL was up to 37% faster than the version with SU drive and offered completely free patterning via data transfer without pattern discs and without mechanical limitations. It also required less maintenance and space.

Expansion to further machine types

Subsequently, NIPPON MAYER's double raschel machines and machines for the production of technical textiles were converted to the EL system.

The lace raschel machines followed later. Thanks to an upgrade for use in high-bar models, the first Multibar Raschel machine with electronic control of all guide bars – a TL 66 – was launched in 2002. The models in this series also had an additional advantage: the compact design of the mechanics allowed the integration of more guide bars and a higher maximum shogging distance for the pattern bars, thus offering greater patterning potential compared to the variants with SU equipment.

Extension to other machine components

At the same time, the price-performance ratio of the EL system was improved, but above all its potential was also exploited for other sub-processes of warp knitting, such as yarn feeding.

Based on EL technology for the tension rail, Advanced Feeding Control (AFC) was developed, which ensures maximum machine performance even with complex patterns involving highly variable yarn consumption. Equipped with the AFC system, the fastest three-bar tricot machine with electronic guide bar control on the market was introduced at ITMA 2023. The newcomer produced a pleated fabric at a speed of 2,900 rpm in front of an astonished audience at the trade fair.

There was also a quantum leap in the field of technical textiles: the warp knitting machine with weft insertion WEFTTRONIC® II G with the new VARIO WEFT laying system was also introduced at ITMA 2023. The weft insertion system does not require any mechanical intervention regarding the threading for weft patterning, has no repeat limitation and reduces edge waste. This is also based on EL technology.

For technology pioneer Georg Kraus, the potential of the EL drive is far from exhausted. In the medium term, he expects it to completely replace the N pattern drive. He also has many ideas for further electronic applications in the warp knitting machine sector.