#Spinning

Great interest in the new Marzoli machines at ITMA

One of them was the Marzoli C701 card, the carding machine with an active surface of 3.74 sqm and with an innovative geometry that allows to reach high production levels with low peripheral speed of the main cylinder for lower stress on the fibers and less wear of the carding flats.

Another the new Marzoli CM7 LP Comber which, thanks to a completely revised kinematics and lighter materials (e.g. aluminum and titanium), can reach a mechanical speed of 600 nips per minute and production levels up to 85 Kg/h. Circular and top combs, thanks to their highly advanced technology and the auto-cleaning system of the top comb, guarantee leading quality performance with a substantial reduction of IPI values. The CM7 LP comber can also be equipped with a cutting-edge automatic lap piecing technology that allows to reliably substitute the empty tubes with the new laps, to piece them and to restart the machine in less than 2 and a half minutes without any human intervention.

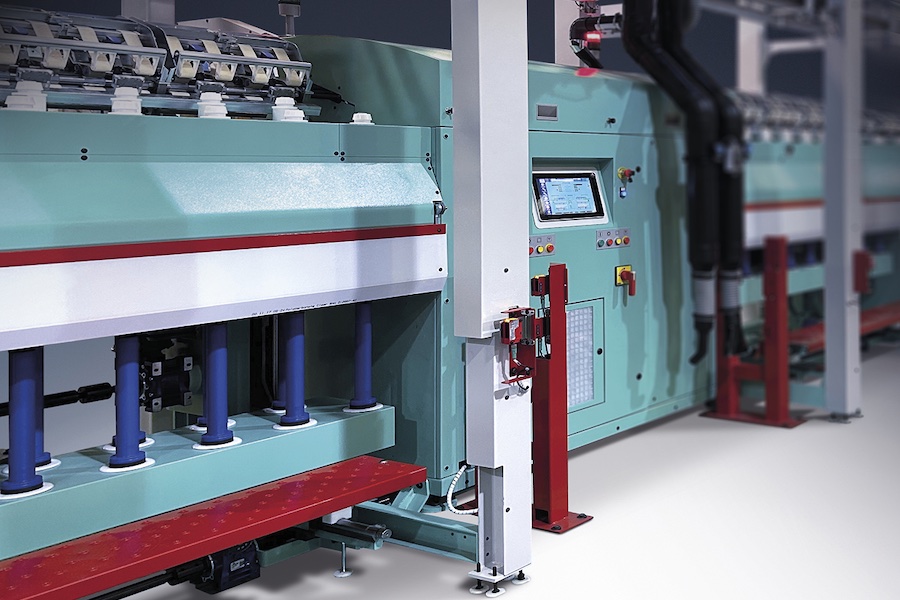

One more highlieght for visitors was the evolution of Marzoli FT6 roving frame of which hereafter are listed some highlights:

- Number of spindles up to 224.

- Multi-motor drive for the flyers to reduce energy consumption.

- New design of head and rear stocks for the reduction of required space.

- Individual sensors, one for each spinning position, to always guarantee the immediate stop of the machine in case of roving breakage.

Also a great interest at ITMA was shown towards the innovative Integrated Bobbin Cleaner placed on the exchanger, the IBC (Marzoli patented). This innovation cleans the dirty tubes before changing them with full bobbins and discloses the following benefits:

- No need of a separate cleaner.

- Fewer chain stops and less chain downtime for a regular supply of full bobbins to the spinning frames, less energy consumption and less stress on the chain components. In traditional transport systems the chain stops for two reasons: because there is a dirty tube in front of the cleaner, because there is an empty tube in front of the exchanger. With the new IBC the chain stops only for one reason, because there is an empty tube in front of the exchanger, and if the tube is dirty then the IBC cleans it.

Marzoli Remote Maintenance (the MRM) also has got a lot of attention. The MRM is the innovative platform that draws on the data gathered by processors and additional sensors installed in critical parts of the machines to continuously monitor the state of health of the machinery. The data regarding temperatures, power consumption and vibrations are sent to an IoT platform, provided by Microsoft, where they are analyzed through special algorithms developed by Marzoli. These algorithms verify that the monitored parameters are inside the machine nominal operating ranges according to the machine working parameters and room condition: if they are not, the client is immediately alerted.

This innovation guarantees several advantages: prevention of machine failures, longer running life of the machine components, more effective maintenance of the mill.