#ITMA 2019

Marzoli “weaving” the future of intelligent spinning at ITMA 2019

“Textile Engineering” – also incorporated in the new institutional logo of Marzoli – perfectly expresses its ability to innovate and work in close contact with Customers, supporting them throughout all phases of the process: from preliminary studies to plant construction, including line start-up, optimisation, management and subsequent commissioning, regardless of whether it is a single machine or complete spinning mill. This evolved approach makes Marzoli, as a Global Partner for the creation of unique solutions exported worldwide, more and more synonymous with production efficiency, flexibility and quality.

Another Company strength is its expertise in developing and combining the most advanced digital technologies, using sensors and integrated diagnostic systems to create smart solutions for predictive maintenance, as well as remote control and management of the plants. More specifically, in collaboration with Camozzi Digital, Marzoli has developed MRM (Marzoli Remote Maintenance): the first patented software platform in the world that analyses the big data of machinery processes detected as mission critical, to continuously monitor operations. This means a reduction of machine downtime, a longer useful life of parts, and more effective and prompter maintenance. Remote control, on the other hand, is made possible by YarNet: a highly innovative software, thanks to which users can easily manage the entire Marzoli spinning process directly from their PC, quickly querying each single machine with ease – a real value-added technology for Customers aiming to maximise productivity and profitability.

The innovative products on show will also include Brain Box: the new patented Marzoli software with an integrated APP, developed entirely in-house, which significantly improves plant performance. In fact, the data emerging from the tests conducted shows a 5.5% increase in productivity, an 8% increase in efficiency, and 1.5% energy savings. Installation is fast and simple, with just four steps: apply the sensors to the individual machines, connect the sensors to Brain Box, download the APP, and activate the monitoring function for the detection of any issues.

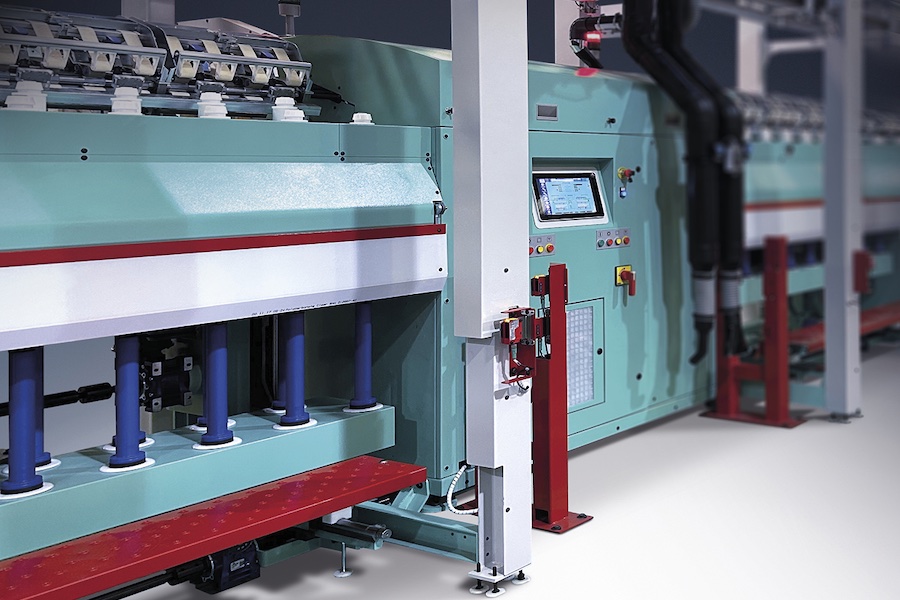

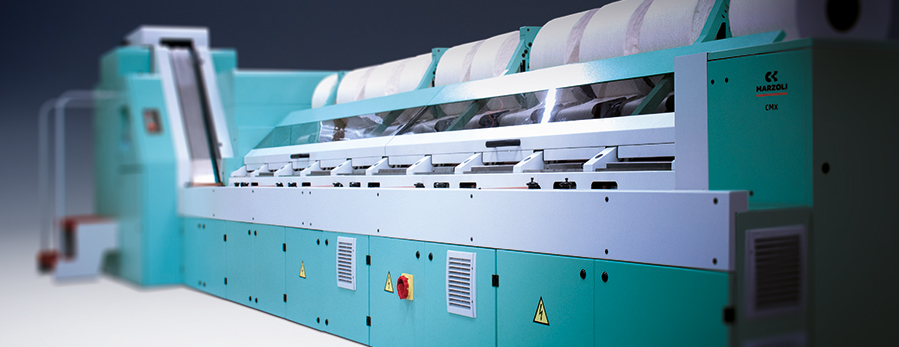

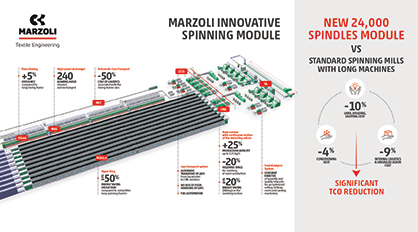

Another main attraction at ITMA will be the innovative 24,000 spinning module by Marzoli, which, compared to traditional spinning lines, enables Customers to achieve a significant reduction in TCO (Total Cost of Ownership) thanks to a 4% cost savings for conditioning, a 10% reduction in investments in the square footage of production sites and a 9% cost savings for internal logistics. At the stand, there will also be a space dedicated to virtual reality, where visitors can take a “tour” of a complete spinning mill. Throughout this unique experience, dedicated video previews will reveal all of the potential and advantages offered by the individual Marzoli machines and solutions, including two additional products being launched: the revolutionary CMX comber and the 2400 spindles MDS2.4 spinning frame.

“Our state-of-the-art CMX machine is a new 10-head combing system which, with a capacity of up to 115kg/hour, guarantees a level of productivity 25% higher than the previous model, along with energy savings equal to 20% kW/kg. Likewise, the 2400 spindles MDS2.4 Hyper Ring spinning frame reduces energy consumption by at least 50%, while ensuring maximum efficiency with reduced investments and low maintenance costs”, stated engineer Cristian Locatelli, General Manager of Marzoli & Camozzi Digital, concluding, “In fact, being a partner for our customers means applying all the expertise and technological know-how at our disposal, to ensure quality advice aimed at developing systems that always operate at peak performance.”

Lodovico Camozzi, President and Chief Executive Officer of the Camozzi Group, commented, “Participation in a prestigious event such as ITMA is crucial for our Group, as an occasion to compare with industry professionals and a precious opportunity to share the high value of Marzoli solutions for spinning of the future. Indeed, we are certain that our vision for constant improvement represents added value for Customers, who can thus aspire to meet new challenging goals and grow in their target markets.