#Nonwovens / Technical Textiles

Energy efficiency in spunlacing

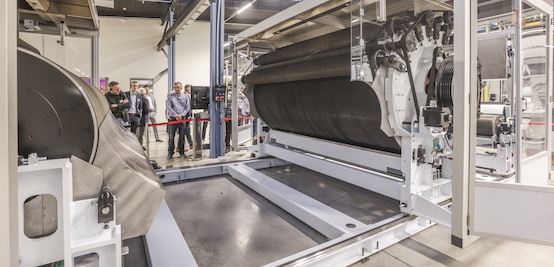

The first MPD installation was erected at Lentex’ site in Lubliniec, Poland in December 2024. Since then, the drying capacity of the line has been significantly increased, while the drying efficiency has been improved by about 30% for Lentex, compared to the previous dryer model. This also helps to cut CO2 emissions, while enabling Lentex to protect the profit margin for its spunlaced materials – against the backdrop of high energy prices in Europe, through improved energy efficiency. On top of this, the new drying equipment was installed without any changes to the company’s production line.

Smooth operators

Trützschler’s team visited Lentex in Lubliniec to conduct extensive tests. Together, they identified the optimal positioning and calibration for their MPD. A seamless integration process was then planned based on Lentex’s production calendar. This process was boosted by open communication and close collaboration, as well as training for Lentex’s staff to ensure smooth integration and operation. The production line was down for approximately one week before operations resumed.

Stronger together

The successful installation of this MPD is the latest milestone in the long and trust-based partnership between Trützschler and Lentex that began in 1999. Lentex operates three spunlace lines and mainly produces sanitary nonwovens using cotton, viscose, polyester, polypropylene fibers, as well as other common man-made fiber types. The close business relationship makes it possible for Trützschler to anticipate the customer’s needs and deliver value-adding solutions – like the MPD.

“Lentex has trusted Trützschler for more than 25 years and this MPD is another valueadding innovation that increases production, cuts costs, supports sustainability and ensures quality for our company.” - Rafal Grabowski, Head of Maintenance at Lentex

The first of many

By switching to the MPD for drying nonwovens, companies like Lentex can mitigate the impact of rising energy prices while positioning themselves as leaders on the journey to sustainability. Importantly, they can make that switch without time-consuming or expensive investments in new production lines. The engineers are celebrating the first successful MPD installation. And they’re excited about more installations as textile producers recognize the advantages of this next-generation dryer.