#Spinning

Big contracts for Marzoli

Marzoli reports that their customers were greatly satisfied when they saw and were able to touch by hand all stages of transformation of raw cotton into quality yarn.

Industry professionals recognized Marzoli’s leading position for its technological advancements in all areas starting with the opening section, then with the card, draw frame, lap winder, roving frame, spinning frame, and last but not least the compact, as well as overall efficiency, quality and cost/quality ratio. During the show Marzoli negotiated contracts for 75 million euros for deliveries starting in June 2012 and accepted orders for 30 million euros. These contracts were made with market leaders and Marzoli feels honored that they choose the company ’s equipment: T.N. Platex, top textile group in Argentina 100,000 spindles for 2012 and 2013 delivery; Sara Spintex India, 25,000 spindles; roving sections in Turkey and India and combing sections in Turkmenistan, Syria and India. Marzoli’s attention to reduction in energy and air consumption was also appreciated, as well as the optimization of waste in the opening, carding and combing process, which creates savings in raw material consumption (<5% Uster Statistics) while producing high quality yarns.

The reputation of Made in Italy has contributed in establishing confidence that comes from the acknowledgement of the production and innovation capabilities that are strictly Italian.

In summary, the most exciting updates brought by Marzoli were:

- Opening section: production up to 1,600 Kg/hr with the introduction of three new machines, model B390L, B380L, B450L with revolutionary concepts of cotton cleaning.

- Card: new model C701 with working height of 1,500 mm and production up to 250 Kg/hr.

- Draw frame: new model DF1 and DFR1 with a production speed up to 1,100 mt/min.

- Lap Winder: new model LW3 with an average speed of 200 mt/min.

- Comber: new model CM7 at 600 c/min, capable of producing up to 100 Kh/hr.

- Roving frame: new models FT6, FT7, FT6D, FT7D with zoned spindle drive.

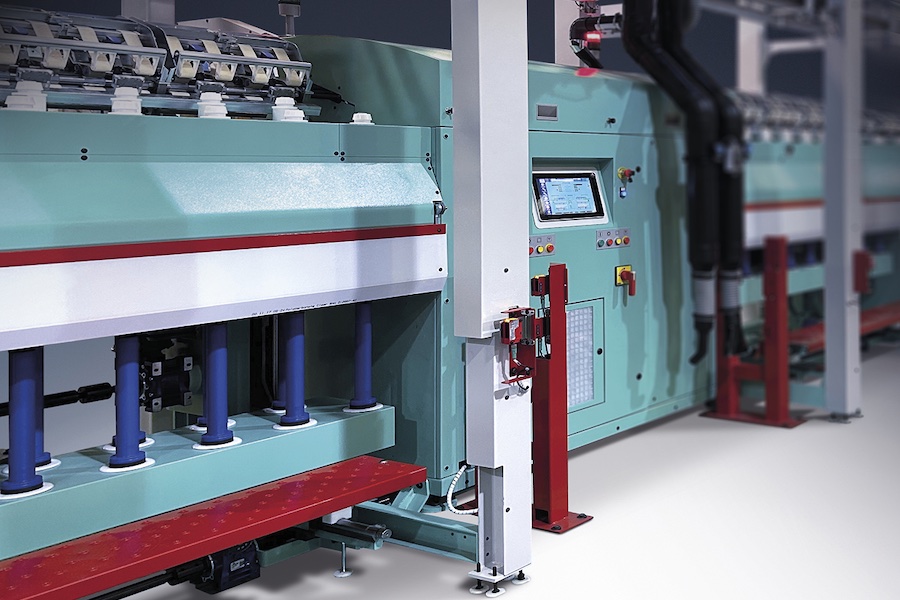

- Spinning frame: new Model MDS up to 1,824 spindles.

Options:

+ Fancy yarn device for longer slubs, large number of slubs and slub designed on a touch screen.

+ Arco Bridge: solution to control fibers during the drawing phase to improve yarn quality.

+ MAC 1: device to produce compact yarn.

Marzoli has a strong vision for the future of the textile industry.

Mr. Mario Bianchetti, Managing Director of Marzoli, gives the following outlook:

“The global economy is going through a radical transformation period. The forecast for the next ten years is for China, India, Mexico, Russia, Brasil and South Korea to generate half of the global economic growth. During the same period the emergent economies will grow at an annual average rate of 4.7%, which is more than double of the growth of advanced economies of 2.3%. In the countries with annual growth around 5%, the textile industry usually is strong and next to the powerhouses of China and India, there are also markets such as Indonesia, Uzbekistan, Turkmenistan, Turkey, Brazil, Bangladesh and Vietnam, where there are investment plans for new installations in the next 3 to 5 years.

Marzoli believes that innovation and globalization, though important, are not sufficient to lead the global market where customer needs and wants and the need to be close to the end users are becoming more and more important. The solution is to join ideas, innovative products and dynamic structures and decentralize them into the individual markets. “

For this reason during the meeting with customers on September 23 (about 200 clients from 20 countries) Marzoli announced the opening of new sales and service centers in the following countries, which are added to the existing service centers in USA and Turkey:

China: Marzoli (Dongtai) Textile Machinery, No. 36 Heduo Bei Road, Dongtai, Jiangsu. India: Bangalore, MTMM, Plot n. 31-C, 2nd Cross, Veerasandra Industrial Area, Hosur Road, Bangalore, Ceo Mr. Anand. Uzbekistan: Taskent, AMT, CEO Federico Fantin.

These are local structures capable of guaranteeing sales, technical, and spare parts support to their customers who are in the design and planning phase or the operation phase of their spinning plant.

The globalization of Marzoli is continuing with the opening of new service centers in other strategic countries, such as: Brazil, Argentina, and Pakistan.