#Smart Textiles

Epson invests in startup AI Silk, a developer and manufacturer of high-performance conductive textiles

Conductive textiles have been used as materials for automotive parts and wearable devices in applications such as biological measurement and EMS1. However, there have been a number of issues. Sensing accuracy can be affected by conductive resistance. The feel and changes in properties (rust) can affect comfort and safety. There have also been issues in terms of manufacturing cost and durability.

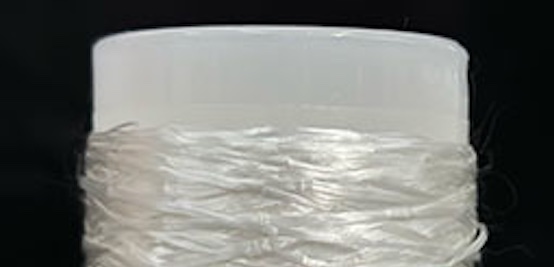

LEAD SKIN®, a high-performance conductive textile developed and manufactured by AI Silk, solves these issues. AI Silk has succeeded in making a variety of materials conductive, including silk, polyester, nonwoven fabrics, and suede. This was achieved by dramatically improving the manufacturing process by adopting a proprietary conductive polymer coating technology based on technology invented at Tohoku University. This technology improves sensing accuracy by reducing conductive resistance. It also improves the feel, texture, comfort, and durability of the textile while also reducing manufacturing costs.

AI Silk intends to use this third-party allotment of shares to expand volume production of LEAD SKIN®. The company plans to expand beyond Japan and to sell LEAD SILK® as a material to meet the growing global demand for automotive parts and wearable devices such as EMS products. It is also considering expanding into the medical field.

Epson aims to give people lifestyle choices and enable them to live enriched lifestyles founded on physical and mental well-being. Epson decided to invest in AI Silk because it sees LEAD SKIN® as an interface technology for converting biological data captured through daily life into new value.

Going forward, Epson will help to achieve a sustainable society by creating a variety of partnerships and synergies based on its proprietary technologies, products, and services.