#Research & Development

DITF produce nonwovens for certified FFP 2 protective masks

Research pilot plant was converted for production

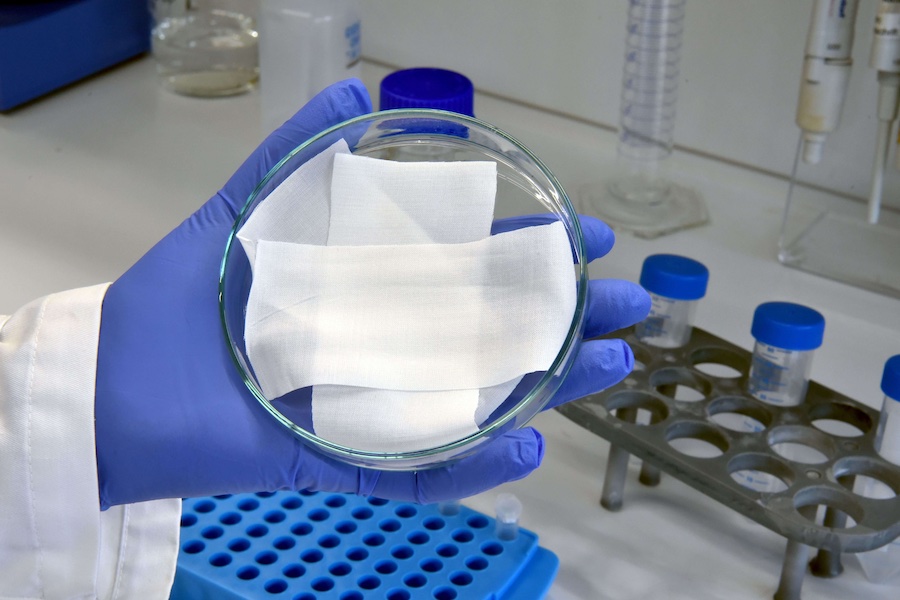

The technical center of the textile research center in Denkendorf is not actually designed for the production of nonwovens for FFP 2 masks. Nevertheless, the team from the Nonwoven Technology Division managed to convert the plant in two weeks so that the material produced could achieve a separation efficiency of FFP 2 level. This material will be used to produce masks that will be worn by doctors and nurses, but also by firefighters and police during the corona pandemic.

The technical equipment is not the only difficulty the team has to master. For example, the scientists are still waiting for the delivery of spunbonded fabric in which the meltblown will be embedded. "We were lucky, however, with the starting material polypropylene for the meltblown, which is not only delivered quickly, but is even donated to us by the company Borealis," explains Professor Götz T. Gresser, board member at the DITF.

The protective masks are assembled by the Junker company and then tested and certified by DEKRA. After successful certification, they are delivered to the Ministry for Social Affairs and Integration of Baden-Württemberg, which coordinates the supply of protective equipment. "As a research institute we cannot produce large quantities, but any quantity helps", emphasizes Professor Michael R. Buchmeiser, Chairman of the Board of Directors of the DITF.

This is why the DITF is not only entering into production, but has been advising companies and organizations in their search for suitable filter media for textile masks since February. The scientists provide information on the normative requirements that the materials must meet and where they can be tested and certified. The DITF were also able to put the Ministry of Social Affairs in touch with one of their network partners who will supply further four million mouth and nose protection masks (MNS).

The DITF also use their procurement infrastructure to support institutions that are currently unable to purchase protective clothing on the market. In this way, 1,000 MNS masks could be passed on to the Denkendorf community.