#Recycling / Circular Economy

Advanced Recycling Conference 2025: From industry crossroads to circularity

On 19-20 November 2025, the Advanced Recycling Conference (ARC) in Cologne, Germany, once more unites industry leaders, technology providers, researchers, innovators, and policy-makers to address urgent recycling challenges in various waste-streams. Alongside core-topics like plastics and polymer recycling, this year’s event places strong emphasis on pollution-intensive sectors like textile and automotive, that pose significant environmental problems due to their complex material streams. While textile recycling rates in the EU remain below 20 %, hindered by difficult fibre blends, automotive plastics und rubbers face regulatory pressure and material complexity under the End-of-Life Vehicle Directive.

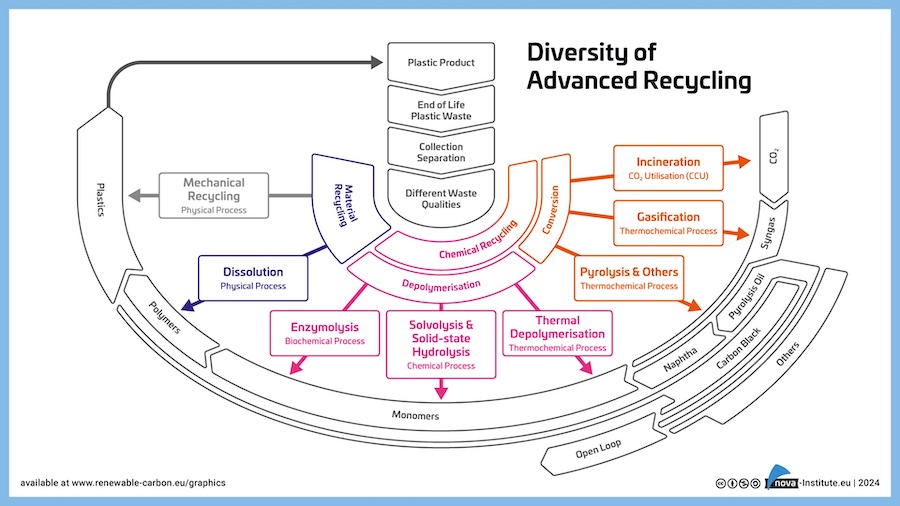

To address these challenges, ARC 2025 spotlights four new focus areas: biochemical recycling, textile and automotive recycling, and advanced digital tools such as AI-enabled sorting, traceability systems, and process optimisation for scale up. These solutions complement established recycling methods across physical processes (extrusion, dissolution), chemical recycling (solvolysis), and thermochemical techniques (pyrolysis, thermal depolymerisation, gasification), as well as carbon capture and utilisation (CCU), that remain key-elements of the ARC program.

At ARC 2025, attendees will gain valuable insights into the latest technological developments, regulatory frameworks, and market conditions shaping the future of advanced recycling and the circular economy. Putting partnership at centre, the event facilitates collaboration and informed decision-making across sectors and industries, proving that sometimes success is only a handshake away.

Responding to EU recycling targets and industry needs

The conference comes at a critical time when significant changes in recycling target across several legislations are taking place. For example, the Packaging and Packaging Waste Regulation introduced quotas for 2030 of recycled post-consumer plastic ranging from 10% to 35% for different packaging plastics which should be increased by 2040. Moreover, the End-of-Life Vehicle Proposal includes a mandate for a minimum of 25% recycled plastic in new vehicles, which, if approved, can considerably increase the demand of recycled post-consumer plastic. Meeting these targets demands the deployment and implementation of innovative recycling technologies and expansion of necessary infrastructure. The event will therefore also address regulatory impacts, market dynamics, and environmental considerations.

Full conference programme now available

Packed with international expertise, ARC 2025 features experts from a broad range of sectors and industries, e.g., BASF, Covestro, Evonik, Fluor, Green Dot, ISCC, LEGO, LyondellBasell, NFIA, Siemens, Sulzer, Trinseo, Vaude, but also research and academic institutions like Chalmers University of Technology, Fraunhofer IVV, Research Centre Jülich, Recycario Data Science – Institut for Economic Plastics Recycling and TU Bergakademie Freiberg (Institute of Energy Process Engineering and Chemical Engineering).

While putting a focus on plastics and polymers, the programme provides a comprehensive overview in different focus-sessions:

+ Advanced Recycling as a Pillar of Renewable Carbon and its Challenges

+ Thermochemical Recycling

+ Biochemical Recycling

+ Textile Sorting and Recycling

+ From Py-Oil Quality to Valuable Resources and the Chain of Custody in Advanced Recycling

+ Recycling Solutions for End-of-Life Vehicles (ELV)

+ Sustainable Polymers

+ Thermochemical Solutions for the Recovery of Valuable Resources and Energy

+ Physical Recycling via Dissolution

The full conference program is available at https://advanced-recycling.eu/program/

The Advanced Recycling Conference provides a unique platform for technology providers, waste management companies, brands, investors, policymakers, and scientists to exchange knowledge, build partnerships, and advance towards circular value chains.

ARC 2025 is supported by visionary sponsors, dedicated to advancing circular solutions. nova-Institute thanks Gold Sponsor Siemens and Bronze sponsors BUSS ChemTech, Erema Group and Starlinger.

The Advanced Recycling Conference is supported by industry and trade associations, non- profit organisations, research institutions and interest groups that are thematically linked to the conference: BCNP Consultants (DE), C.A.R.M.E.N. (DE), ChemCologne (DE), Chemical Recycling Europe (EU), Chemie-Cluster Bayern (DE), CLIB (DE), IBB Netzwerk (DE), ITA - International Centre for Sustainable Textiles (DE), kunststoffland.NRW (DE), Plastics Europe (DE), Renewable Carbon Initiative (International).

For detailed information and registration, visit https://advanced-recycling.eu/