#Nonwovens / Technical Textiles

Toray launches LIVMOA™ 4500AS disposable personal protective clothing conforming with Japanese standard for Chemical Spray Resistance

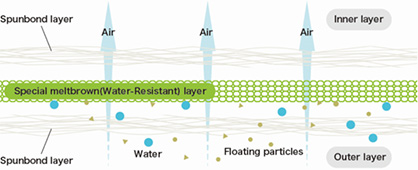

Cross-section of LIVMOA™ 4500AS fabric

Toray developed the fabric for this product in 2021. It employs a highly durable SMS (spunbond + dense, water-resistant meltblown + spunbond) nonwoven, antistatic fabric. This fabric protects against dust and can withstand a water pressure of 1,000mm H2O (where the water pressure resistance at seams is less than 1,000 mm H2O), which is hard to achieve with regular SMS fabric. Toray believes that LIVMOA™ 4500AS is the world's first clothing to be Type 4-compliant while delivering an air permeability of around 7 cc/cm2 per second.

This new product can provide protection in a variety of tasks in which water resistance is vital. They include controlling dioxin levels at waste incineration facilities and performing major regular factory repairs. They also encompass work at chemical plants, maintenance, working in dirty areas, or removing asbestos.

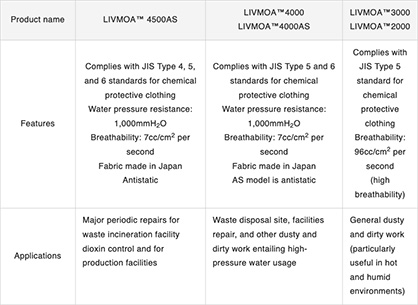

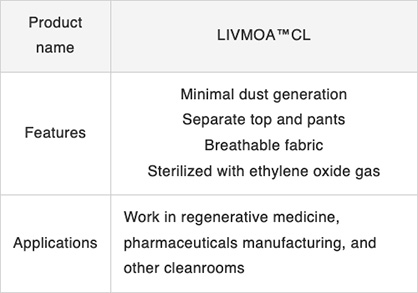

Since debuting the LIVMOA™ series in 2017, Toray has broadened the lineup to cater to diverse applications, including dust protection, infection control, and clean rooms. It will keep developing offerings that combine comfort and functionality for various needs.

Key goals of Toray Group Sustainability Vision are to help enhance medical care and public health by leveraging innovative technologies and advanced materials. Toray will keep drawing on its advanced materials technologies to develop high-value-added materials that will contribute to the environment, health, safety, and disaster prevention. It will thereby realize its corporate philosophy of contributing to social progress by delivering new value while attaining sustainable growth.

LIVMOA™ 4500AS details

1. Features

(1) Proprietary SMS fabric withstands water pressure of 1,000mm H2O (using JIS L 1092 A method)

(2) Seam tape applied on back

(3) Breathability (around 7 cc/cm2 per second) reduces stuffiness inside clothing (using JIS L 1096 A method)

(4) Chemical protective clothing compliance

JIS T 8115 :2015 Type 4 (“Spray-tight” chemical protective clothing )

JIS T 8115:2015 Type 5 (Chemical protective clothing providing protection against airborne solid chemicals)

JIS T 8115:2015 Type 6 (Chemical protective clothing with “limited protective performance against liquid chemicals”)

(5) Fabric produced at domestic Toray plant

2.Sizes : XS, S, M, L, XL, 2XL

3. Applications : Dusty and dirty work requiring water protection

4. Launch timing : May 2022

5. Distributor : Sunrich Mode Inc. (available from tool, uniform, health and sanitary product, and other suppliers)

6. Retail price : Discretionary

7. Availability : From tool, uniform, health and sanitary product, and other suppliers

LIVMOA™ website:

https://www.livmoa.toray/

LIVMOA™ Series Lineup

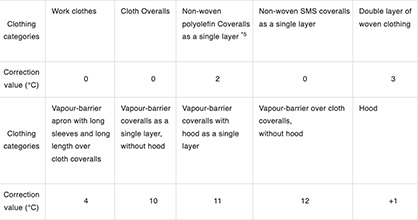

WBGT Clothing adjustment values for LIVMOA™

Personal Protective clothing is important to keep safe and hygiene for workers from harmful substances, but heat stroke prevention measures are also important because it is difficult to donning and doffing at the wearer's own discretion.

The Ministry of Health, Labor and Welfare, the Prefectural Labour Bureau, and the Labor Standards Inspection Office launched a campaign encompassing a range of measures to prevent occupational heat stroke. They include monitoring Wet Bulb Globe Temperature (WGBT) index values and providing breathable work clothing. The campaign also accords top priority to protective clothing materials choices.

The WBGT heat index aims to prevent heat stroke by tracking heat exchanges between the human body and the surrounding air. It takes into account key factors in these disorders. Among them are temperature, humidity, wind speed, radiant heat, physical work intensity, and the heat characteristics of work apparel.

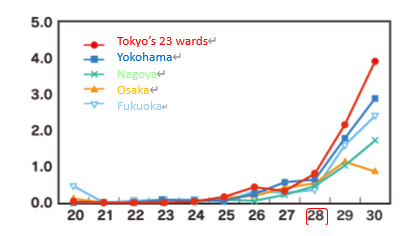

Daily heat stroke case per million people

The chart shows that that heat stroke cases surge significantly when WBGT index exceeds 28°C (heightened alert).

Depending on fabrics of protective clothing worn, an example being items made with non-breathable fabrics, WBGT values at work sites may need adding to clothing adjusting values in the table below. Typical fabrics of protective clothing is in the category of “Non-woven polyolefin Coveralls as a single layer” with a clothing adjusting value of +2°C. Excluding LIVMOA™ 5000, LIVMOA™ fabrics are in the category with a clothing adjusting value of 0°C and suitable for using hot work sites.

Clothing adjustment values added to WBGT values according to clothing combinations (based on Outline of Basic Measures to Prevent Heat Disorders in Workplaces by Ministry of Health, Labour and Welfare).