#Market Analysis & Forecasts

Specialty polymers market to grow 7.4% CAGR, reaching $153.6 billion by 2030

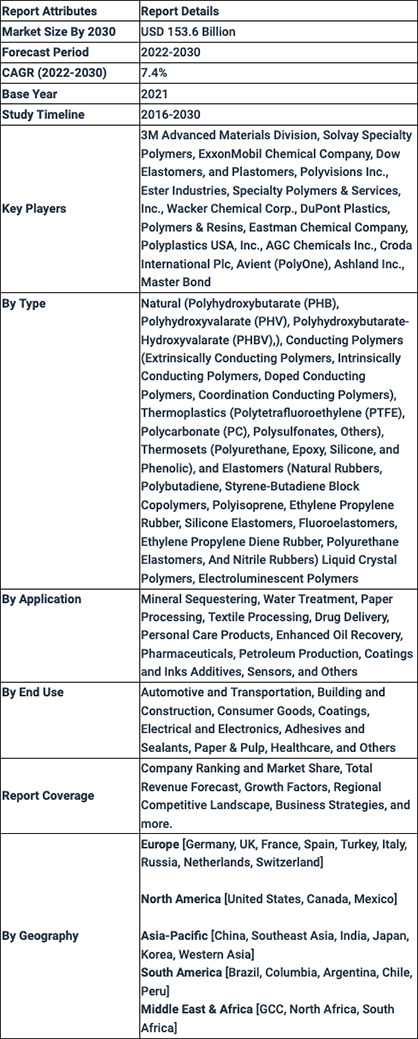

The market is expected to register a CAGR of 7.4% during the forecast period 2022-2030, reaching USD 153.6 Billion by the end of 2030, Major specialty polymers market participant are 3M Advanced Materials Division, Solvay Specialty Polymers, ExxonMobil Chemical Company, Dow Elastomers, and Plastomers, Polyvisions Inc., Ester Industries, Specialty Polymers & Services, Inc., Wacker Chemical Corp., DuPont Plastics, Polymers & Resins, and Others

As per the research report Specialty Polymers Market published by Reports Insights, the market was valued at USD 86.8 Billion in 2022 and is estimated to reach over USD 153.6 Billion by the year 2030, growing at a CAGR of 7.4%.

Specialty Polymers Market By Type (Natural, Conducting Polymers, Thermoplastics, Thermosets, Elastomers, Liquid Crystal Polymers, and Electroluminescent Polymers), By Application (Mineral Sequestering, Water Treatment, Paper Processing, Textile Processing, Drug Delivery, Personal Care Products, Enhanced Oil Recovery, Pharmaceuticals, Petroleum Production, Coatings and Inks Additives, Sensors, and Others), By End Use (Automotive and Transportation, Building and Construction, Consumer Goods, Coatings, Electrical and Electronics, Adhesives and Sealants, Paper & Pulp, Healthcare, and Others), By Region and Segment, Forecast Period 2022 – 2030. Specialty polymers include natural, conducting, thermoplastics, thermosets, elastomers, liquid crystal, and electroluminescent polymers and are used in applications such as mineral sequestering, water treatment, paper processing, textile processing, drug delivery, personal care, enhanced oil recovery, pharmaceuticals, petroleum production, coatings and inks additives, sensors, and others. The market is segmented by end-use industry, including automotive and transportation, building and construction, consumer goods, coatings, electrical and electronics, adhesives and sealants, paper & pulp, healthcare, and others. The Asia-Pacific region is expected to be the largest market for specialty polymers, due to the presence of numerous end-use industries and growing demand for high-performance materials in countries like China and India.

Get Sample Report@ https://www.reportsinsights.com/sample/673724

Specialty polymers are a type of polymer with unique physical and chemical properties, designed for specific applications. These polymers offer enhanced properties such as high strength, temperature resistance, optical clarity, biocompatibility, flame resistance, conductivity, and others. Specialty polymers are used in various industries including electronics, medical devices, automotive, packaging, and construction. For instance, specialty polymers include polyphenylene oxide (also known as polyphenylene ether (PPE)), polyvinylidene fluoride, polyether ether ketone, and silicone rubber.

Further, the versatility and customized properties of specialty polymers make them an important part of modern manufacturing and product development. In the electronics industry, specialty polymers are used to produce high-performance electrical and electronic components. However, in the medical field, these polymers are used to produce implantable devices and disposable products. In the automotive industry, they are used to produce lightweight and durable components, while in the packaging, they are used for food packaging, containers, and labels.

Moreover, specialty polymers offer enhanced physical and chemical properties, which result in improved product performance and quality. Thus, such capability of producing high-performance products offers a competitive advantage specifically for manufacturers and a positive brand reputation for the products they produce. Also, specialty polymers offer opportunities to be tailored as per specific applications that help manufacturers gain the ability to create custom-made products for meeting the specific needs of their target customers. Such customization offers the chance to market players in terms of improved product differentiation and increased market appeal.

Specialty Polymers Market Report Scope:-

Key Market Highlights

- The global specialty polymers market size is estimated to surpass USD 153.6 billion by 2030 and grow at a CAGR of 7.4% during the forecast period (2022-2030).

- Globally, specialty polymers are divided based on the type into natural, conducting polymers, thermosets, thermoplastics, elastomers, liquid crystal polymers, and electroluminescent polymers.

- In the context of the application, the market is separated into mineral sequestering, water treatment, paper processing, textile processing, drug delivery, personal care products, enhanced oil recovery, pharmaceuticals, petroleum production, coatings and ink additives, sensors, and others.

- Further, the end-use segment comprises nine aspects: automotive and transportation, building and construction, consumer goods, coatings, electrical and electronics, adhesives and sealants, paper & pulp, healthcare, and others.

- The market is geographically segregated into five regions: Europe, North America, the Asia-Pacific, South America, and the Middle East and Africa.

- Asia Pacific and North America are expected to support industry growth in terms of the growing requirement for high-performance products in multiple sectors such as electronics, automotive, and construction to support the growing population demand.

Specialty Polymers Market Segmentation Details:

Based on type, the elastomers segment is anticipated to support the market growth in terms of the largest share contribution. Elastomers are further sub-segmented into natural rubbers, polybutadiene, styrene-butadiene block copolymers, polyisoprene, ethylene propylene rubber, silicone elastomers, fluoroelastomers, ethylene propylene diene rubber, polyurethane elastomers, and nitrile rubbers. These elastomers are Injection moldable, extrudable, and thermoformable along with capabilities of blow moldable processing. Further, they are primarily preferred by manufacturers due to their high resistance to physical impact and chemical cleaners.

Based on application, the other segment is projected to contribute major shares to the market growth in terms of volume. Other applications comprise floor coverings, clothing, packaging, and garbage disposal bags, along with automobile parts, pipes, windshields for fighter planes, tanks, insulation additives, packing materials, adhesives, wood substitutes, infrared heaters, and matrix for composites. Such applications demand wide usage of specialty polymers, especially low-density polyethylene (LDPE), high-density polyethylene (HDPE), polyvinyl chloride (PVC), and polypropylene (PP)

Based on end use, the automotive and transportation segment is expected to contribute substantial shares to the market growth in terms of value. Specifically, specialty elastomers are mainly used in manufacturing several automotive applications. Such elastomers offer high freedom in terms of designing interior as well as exterior parts. Further, they also aid in improving overall durability by offering great haptic properties, and resistance to abrasion and vibration. For instance, polypropylene is largely used in automotive components that range from bumpers to carpet fibers and cable insulation due to durability and chemical resistance

Based on region, Asia Pacific is anticipated to contribute substantial shares in terms of value. A large proportion of consumer goods, specialty chemicals, and other manufactured products are mainly manufactured in Asia Pacific. Thus, the increased exports and imports of such products are expected to propel market growth in this region. Moreover, the growing initiatives and expenditures by market players to improve the market growth also propel the market statistics especially in developing economies such as India, Japan, and Indonesia.

Browse Full Report @

https://www.reportsinsights.com/industry-forecast/global-specialty-polymers-market-statistical-analysis-673724

Recent Developments

- In January 2022, a chemical manufacturing firm based in Saudi named SABIC introduced the latest portfolio of specialty polymers named the LNP™ ELCRIN™ CRX7416UB and LNP™ ELCRIN™ CRX7412UB.

- In March 2022, Avient (formerly known as PolyOne) developed Nymax™ BIO Formulations, which are a cost-effective and durable product range of bio-based polyamides (PA) with the major property as a flame-retardant.

- In June of 2022, BASF introduced a specially optimized resin called Ultramid A3EM8 OP, which is designed for key painting purposes.

- In October 2022, NOVA Chemicals launched the latest EX-PCR-NC4 resin that is entirely created from recycled polyethylene post-consumer usage.

List of Major Specialty Polymers Market Players

The market research report examines several market factors to analyze the key market dynamics which include drivers, restraints, and opportunities of the market circumstances. Additionally, a detailed regional analysis is also offered to identify growth opportunities across various countries. Multiple factors such as product applications, innovative technologies, the latest product launches, and business strategies are also taken into consideration to gain an in-detailed evaluation of the overall industry. The following are key players that comprise the market circumstances—

3M Advanced Materials Division

Solvay Specialty Polymers

ExxonMobil Chemical Company

Dow Elastomers and Plastomers

Polyvisions Inc.

Ester Industries

Specialty Polymers & Services, Inc.

Wacker Chemical Corp.

DuPont Plastics, Polymers & Resins

Eastman Chemical Company

Polyplastics USA, Inc.

AGC Chemicals Inc.

Croda International Plc

Avient (PolyOne)

Ashland Inc.

Master Bond

Global Specialty Polymers Market Segmentation:

By Type

Natural

Polyhydroxybutarate (PHB)

Polyhydroxybutarate-Hydroxyvalarate (PHBV)

Polyhydroxyvalarate (PHV)

Conducting Polymers

Extrinsically Conducting Polymers

Intrinsically Conducting Polymers

Doped Conducting Polymers

Coordination Conducting Polymers

Thermoplastics

Polytetrafluoroethylene (PTFE)

Polycarbonate (PC)

Polysulfonates

Others

Thermosets

Polyurethane

Epoxy

Silicone

Phenolic

Elastomers

Natural Rubbers

Polybutadiene

Styrene-Butadiene Block Copolymers

Polyisoprene

Ethylene Propylene Rubber

Silicone Elastomers

Fluoroelastomers

Ethylene Propylene Diene Rubber

Polyurethane Elastomers

Nitrile Rubbers

Liquid Crystal Polymers

Electroluminescent Polymers

By Application

Mineral Sequestering

Water Treatment

Paper Processing

Textile Processing

Drug Delivery

Personal Care Products

Enhanced Oil Recovery

Pharmaceuticals

Petroleum Production

Coatings and Inks Additives

Sensors

Others

By End Use

Automotive and Transportation

Building and Construction

Consumer Goods

Coatings

Electrical and Electronics

Adhesives and Sealants

Paper & Pulp

Healthcare

Others